Sulfur and selenium compound coated with conducting polymer and oxidized graphene and preparation and application thereof

A conductive polymer and selenium compound technology, applied in the field of electrochemistry, can solve the problems of poor electrochemical performance, achieve high conductivity, improve electrochemical performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

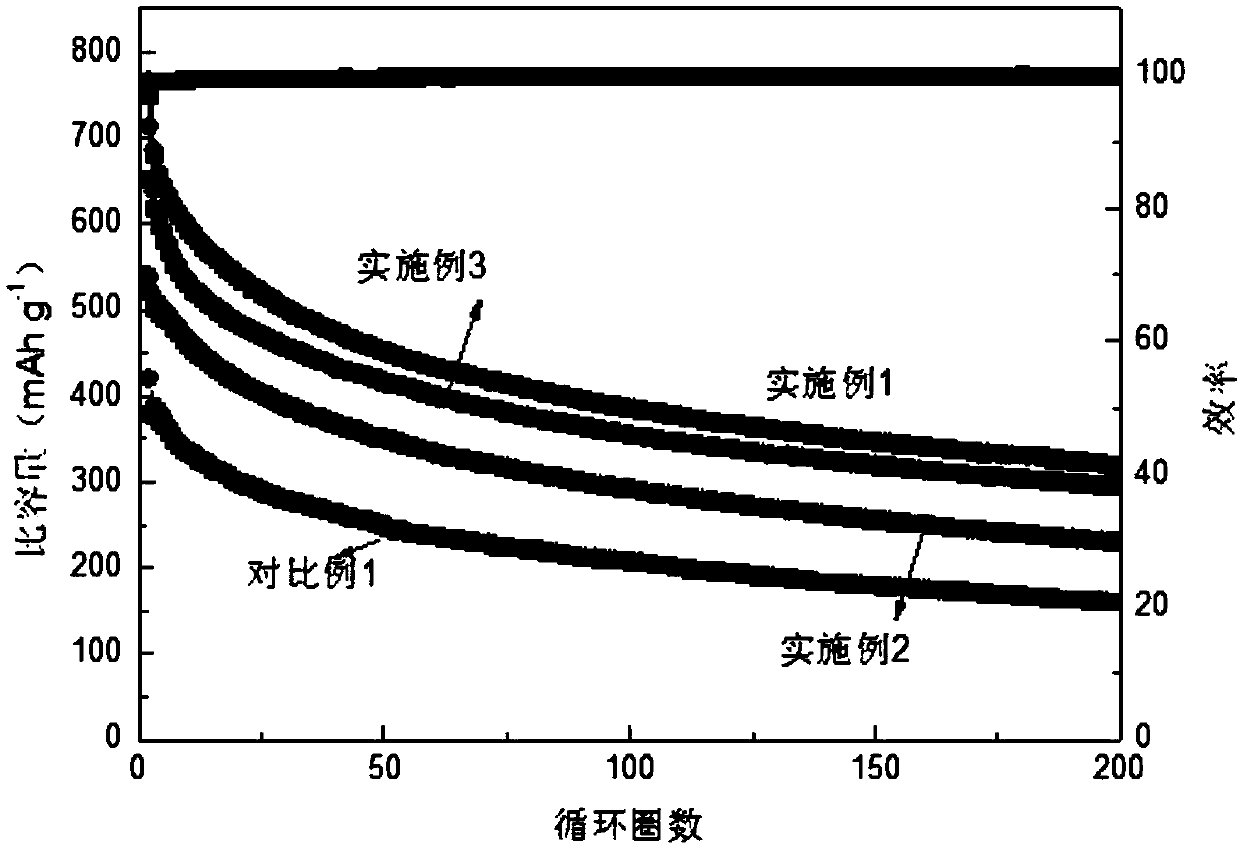

[0029] Preparation of double-layer coated positive electrode materials for selenium sulfide batteries: 2g of polyvinylpyrrolidone (surfactant) and 0.346g of sodium selenite were dissolved in 50mL of water, and 0.96g of sodium sulfide was ultrasonically dissolved in 30mL of water and added To the above solution, then add 2mol / L HCl dropwise until the pH reaches 2. React for 12 hours, centrifuge and wash.

[0030] Then dissolve the sample after centrifugation in 100mL water, add 120uL 3,4-ethylenedioxythiophene, 0.12g camphorsulfonic acid, and 0.6g ammonium persulfate in sequence, and change to dark green after coating for 12 hours. After centrifugation, dissolve it in 100mL water. At the same time, 0.1 mg / mL graphene oxide aqueous solution was added, stirred and coated for 2 hours, centrifuged, dried at 80°C, and the sample was dried to obtain a composite material of selenium sulfide / polythiophene / graphene oxide. Then the composite material, acetylene black, and polyvinylidene...

Embodiment 2

[0033] Preparation of double-coated positive electrode materials for selenium sulfide batteries: 2 g of polyvinylpyrrolidone and 0.346 g of sodium selenite were dissolved in 50 mL of water, and 0.96 g of sodium sulfide was ultrasonically dissolved in 30 mL of water and added to the above solution. Then add 2mol / L HCl dropwise until the pH reaches 2. React overnight, centrifuge and wash.

[0034] Then dissolve the centrifuged sample in 100mL water, add 120uL aniline, 240uL concentrated hydrochloric acid, and 0.2g ammonium persulfate in sequence, and change to dark green after coating for 12 hours. After centrifugation, dissolve it in 100mL water, and add 0.1mg / mL graphene oxide at the same time The aqueous solution was stirred and coated for 2 hours, centrifuged, dried at 80° C., and the sample was dried to obtain a composite material of selenium sulfide / polyaniline / graphene oxide. Then the composite material, acetylene black, and polyvinylidene fluoride were uniformly mixed a...

Embodiment 3

[0037] Preparation of double-coated positive electrode materials for selenium sulfide batteries: 2 g of polyvinylpyrrolidone and 0.346 g of sodium selenite were dissolved in 50 mL of water, and 0.96 g of sodium sulfide was ultrasonically dissolved in 30 mL of water and added to the above solution. Then add 2mol / L HCl dropwise until the pH reaches 3. React overnight, centrifuge and wash.

[0038] Then, the centrifuged sample was dissolved in 100mL water, and 100uL pyrrole, 0.15g FeCl 3 , 0.02g sodium lauryl sulfate, coated for 12h to turn dark green, dissolved in 100mL water after centrifugation, and added 0.1mg / mL graphene oxide aqueous solution at the same time, stirred and coated for two hours, centrifuged, dried at 80°C The sample was obtained to obtain a composite material of selenium sulfide / polypyrrole / graphene oxide. Then the composite material, acetylene black, and polyvinylidene fluoride were uniformly mixed at a mass ratio of 7:2:1, and ball milled to obtain a unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com