Ultra-small vanadium carbide embedded carbon atom layer material and preparation method thereof

A technology of carbon atoms and ultra-small carbons, applied in chemical instruments and methods, carbon compounds, nanotechnology for materials and surface science, etc., can solve the problems of difficult to meet the requirements of electrocatalysts, easy agglomeration, and difficult to refine the particle size, etc. problems, to achieve excellent hydrogen production activity, high stability, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: get 1.625g of dicyandiamide, 0.025g of ammonium metavanadate and 0.225g of cobalt nitrate hexahydrate, mix and fully grind to obtain reactant raw materials;

[0025] Step 2: Put the raw material of the reactant in a porcelain boat, place it in a tube furnace under an argon atmosphere, and raise the temperature from room temperature to 800°C at a heating rate of 5°C / min, and keep it warm for 4 hours to obtain a black powder;

[0026] Step 3: Put the black powder in 0.5mol / L H 2 SO 4 After vacuum drying for 10 h, the ultra-small vanadium carbide intercalated carbon atomic layer material (VC@CL hydrogen-producing electrocatalyst) was obtained.

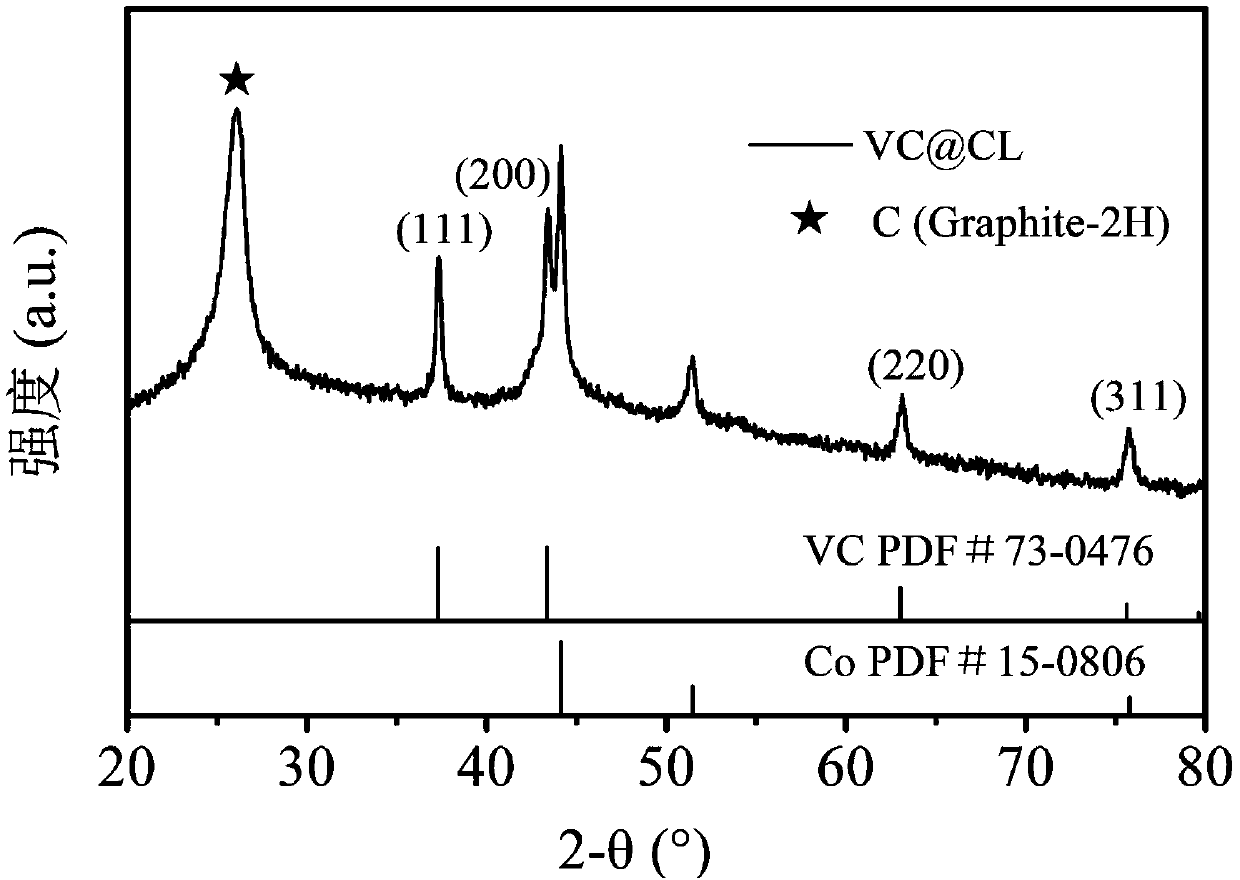

[0027] Depend on figure 1 It can be seen that the prepared ultra-small vanadium carbide embedded carbon atomic layer material (VC@CL hydrogen production electrocatalyst) corresponds to the VC standard PDF card number 73-0476, and the four diffraction peaks correspond to the crystal planes (111), (200) , (220) and (311), ...

Embodiment 2

[0029] Step 1: get 1.625g of dicyandiamide, 0.025g of ammonium metavanadate and 0.3g of cobalt nitrate hexahydrate, mix and fully grind to obtain reactant raw materials;

[0030] Step 2: Put the raw material of the reactant in a porcelain boat, place it in a tube furnace under an argon atmosphere, raise the temperature from room temperature to 500°C at a rate of 5°C / min, and keep it warm for 2 hours to obtain a black powder;

[0031] Step 3: Put the black powder in 0.5mol / L H 2 SO 4 After 15 hours in the vacuum, the ultra-small vanadium carbide intercalated carbon atomic layer material (VC@CL hydrogen production electrocatalyst) was obtained after vacuum drying.

Embodiment 3

[0033] Step 1: get 2g of dicyandiamide, 0.025g of ammonium metavanadate and 0.25g of cobalt nitrate hexahydrate, mix and fully grind to obtain reactant raw materials;

[0034] Step 2: Put the raw material of the reactant in a porcelain boat, place it in a tube furnace under a nitrogen atmosphere, and raise the temperature from room temperature to 1000°C at a heating rate of 7°C / min, and keep it warm for 1 hour to obtain a black powder;

[0035] Step 3: Put the black powder in 0.5mol / L H 2 SO 4 After vacuum drying for 20 h, the ultra-small vanadium carbide intercalated carbon atomic layer material (VC@CL hydrogen-producing electrocatalyst) was obtained.

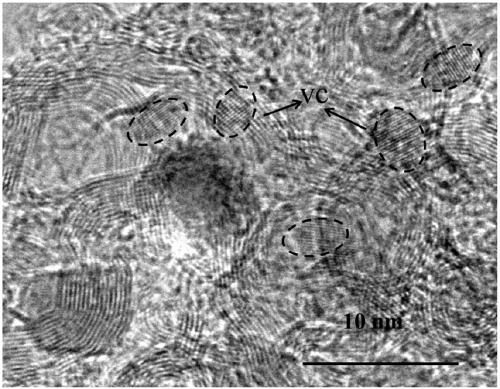

[0036] Depend on figure 2 It can be seen that the microstructure of the prepared ultra-small vanadium carbide embedded carbon atomic layer material (VC@CL hydrogen production electrocatalyst) is vanadium carbide coated with carbon atomic layer, and the particle size of vanadium carbide is less than 3nm. The crystal plane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com