Preparation method and application method of phosphor-based modified charcoal

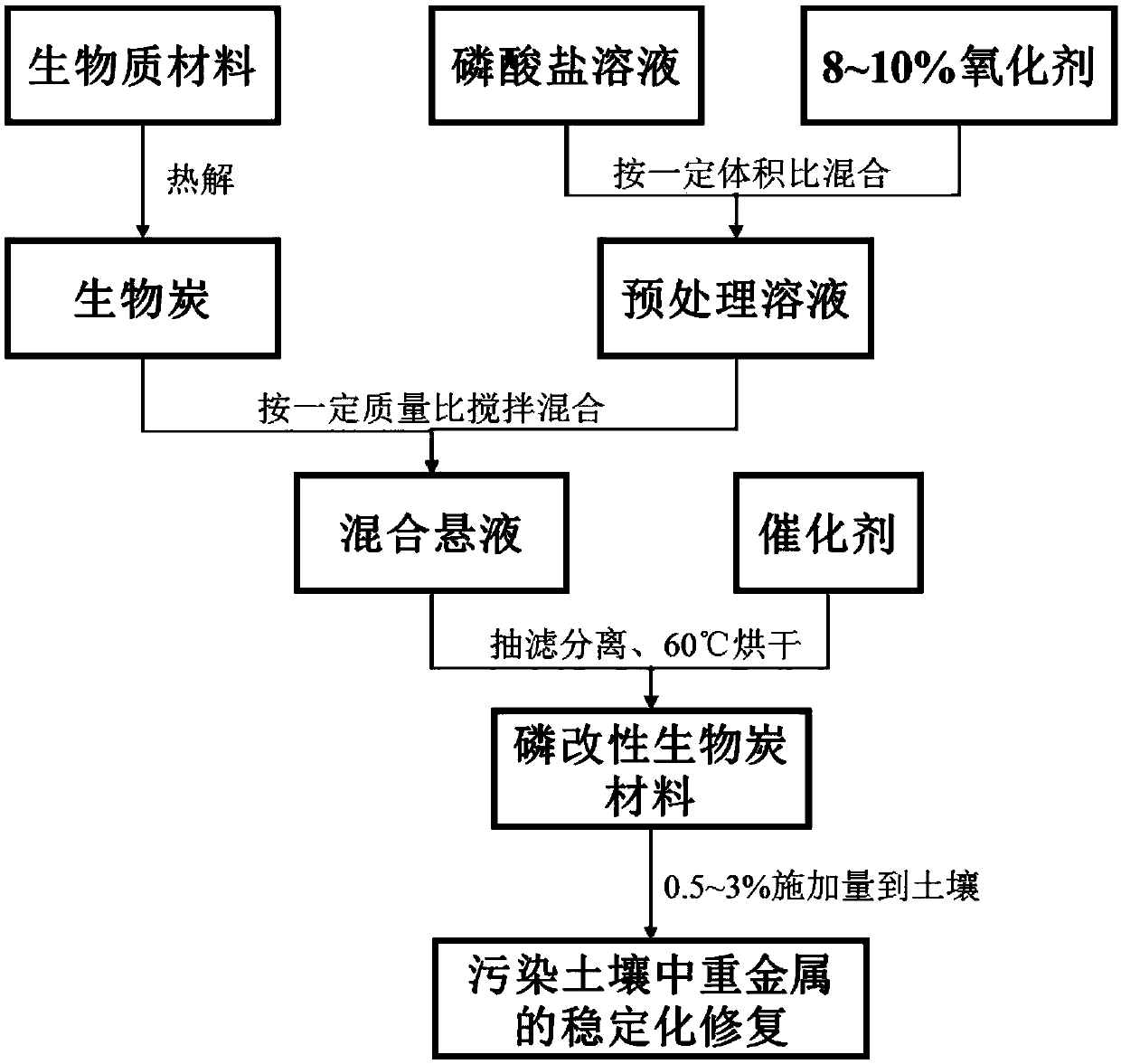

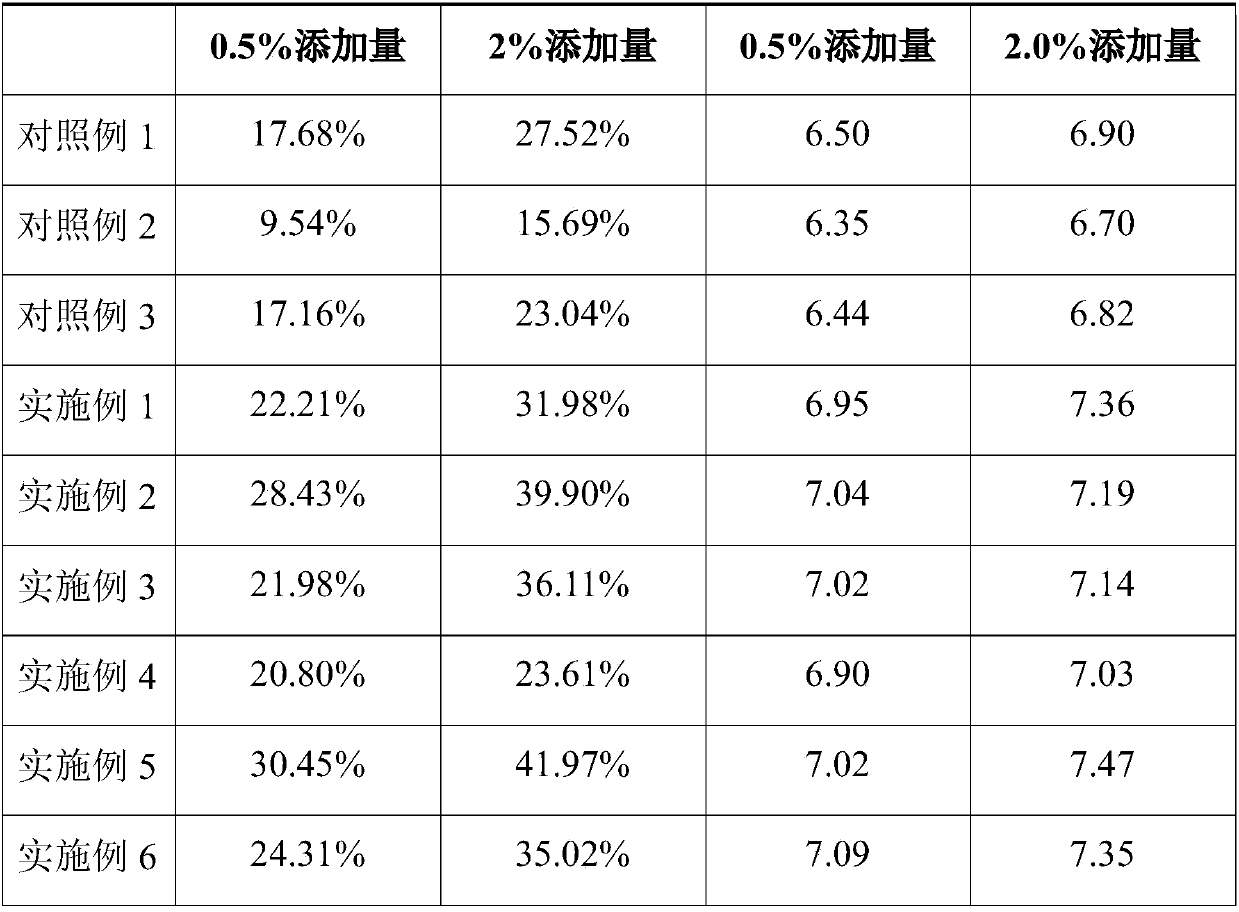

A biochar, modified technology, applied in the application, chemical instruments and methods, fertilizer mixtures and other directions, can solve the problems affecting the fertility effect of the preparation material, the stabilization ability of heavy metals, the effectiveness and reduction of the loss of phosphorus bases, and achieve stability. Chemical repair, simple use process, preparation method and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a phosphorus-based modified biochar material, which is mainly prepared by the following steps:

[0031] (1) Wash the agricultural surplus wheat straw material with deionized water, then dry it at 80°C for 24 hours, put it into a tube furnace for pyrolysis and firing after crushing, and inject N into the tube at a flow rate of 400mL / min. 2 Under anaerobic and 400°C conditions, pyrolyze for 6 hours to prepare the biochar, and then grind the biochar through a 60-mesh sieve to form a powder for later use;

[0032] (2) The preparation concentration is 10g / L potassium dihydrogen phosphate solution, and the mass fraction of hydrogen peroxide solution is diluted to 8%; the above potassium dihydrogen phosphate solution and hydrogen peroxide solution are mixed in a volume ratio of 2.5:1 to obtain a pretreatment solution;

[0033] (3) Fully mix the pretreatment solution obtained in (2) with the ground powdery biochar obtained in (1) according to a mass rat...

Embodiment 2

[0036] This embodiment provides a phosphorus-based modified biochar material, which is mainly prepared by the following steps:

[0037] (1) Wash the agricultural surplus wheat straw material with deionized water, then dry it at 80°C for 24 hours, put it into a tube furnace for pyrolysis and firing after crushing, and inject N into the tube at a flow rate of 400mL / min. 2 Under anaerobic and 300°C conditions, pyrolyze for 8 hours to prepare the biochar, and then grind the biochar through a 60-mesh sieve to form a powder for later use;

[0038] (2) The preparation concentration is 15g / L dipotassium hydrogen phosphate solution, and the mass fraction of hydrogen peroxide solution is diluted to 8.5%; the above dipotassium hydrogen phosphate solution and hydrogen peroxide solution are mixed in a volume ratio of 3:1 to obtain a pretreatment solution;

[0039] (3) Fully mix the pretreatment solution obtained in (2) with the ground powdered biochar obtained in (1) according to a mass ra...

Embodiment 3

[0042] This embodiment provides a phosphorus-based modified biochar material, which is mainly prepared by the following steps:

[0043] (1) Wash the agricultural surplus corn stalks with deionized water, then dry them at 80°C for 24 hours, put them into a tube furnace for pyrolysis and firing after crushing, and inject N into the tube at a flow rate of 400mL / min. 2 Under anaerobic and 600°C conditions, pyrolyze for 3 hours to prepare the biochar, and then grind the biochar through a 60-mesh sieve to form a powder for later use;

[0044] (2) The preparation concentration is 20g / L sodium dihydrogen phosphate solution, and the mass fraction of hydrogen peroxide solution is diluted to 9.0%; the above sodium dihydrogen phosphate solution and hydrogen peroxide solution are mixed in a volume ratio of 4:1 to obtain a pretreatment solution;

[0045] (3) Fully mix the pretreatment solution obtained in (2) with the ground powdered biochar obtained in (1) according to a mass ratio of 4:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com