Liquid chromatography tandem mass spectrometry detection method for measuring phthalates plasticizer in aquatic processing product

A medium phthalate, liquid chromatography technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to meet the rapid and advanced analysis technology, hinder the census of phthalate pollutants, consume large organic solvents, etc. High extraction efficiency and target yield, low equipment requirements, and simple and easy-to-control operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

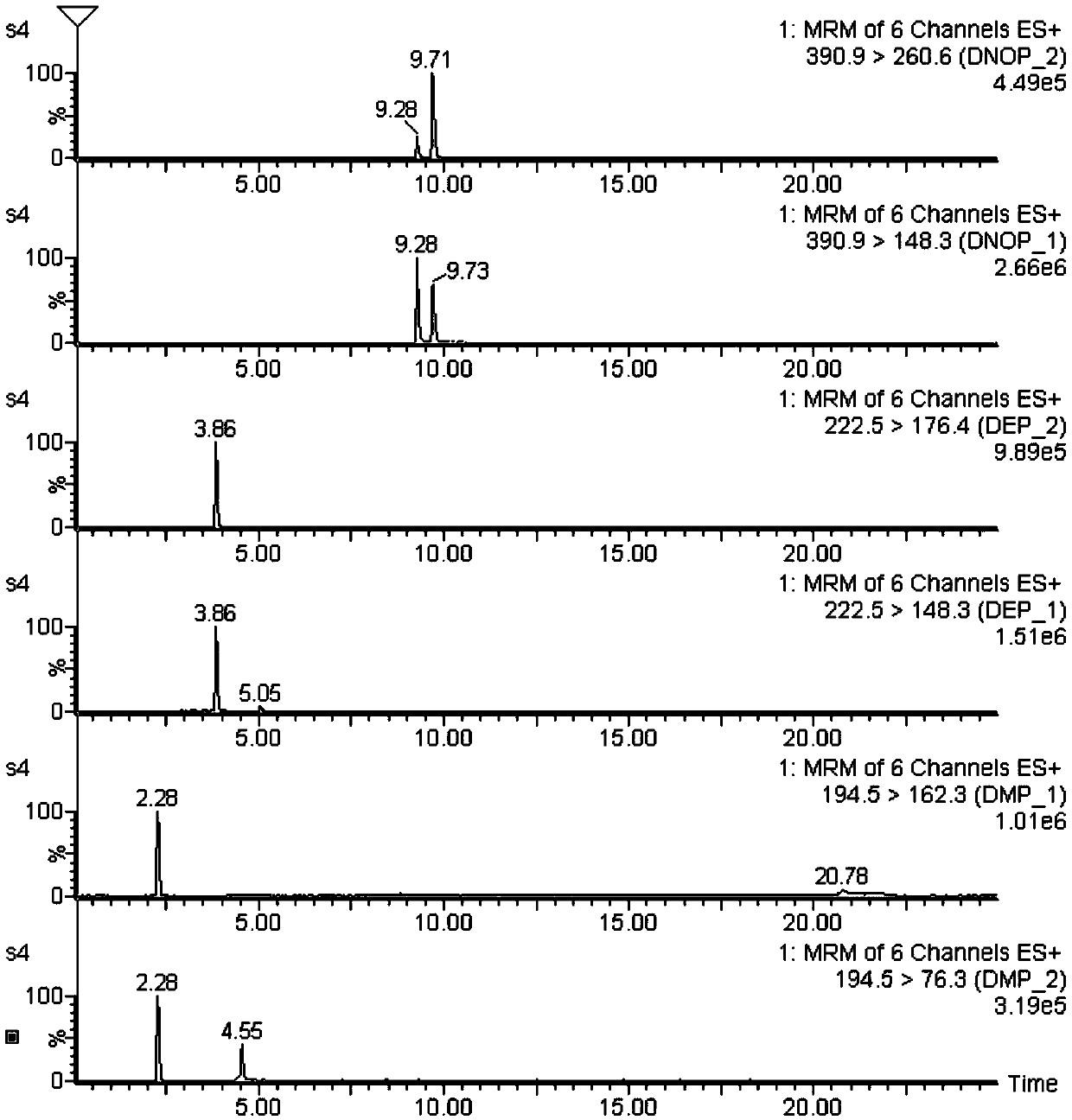

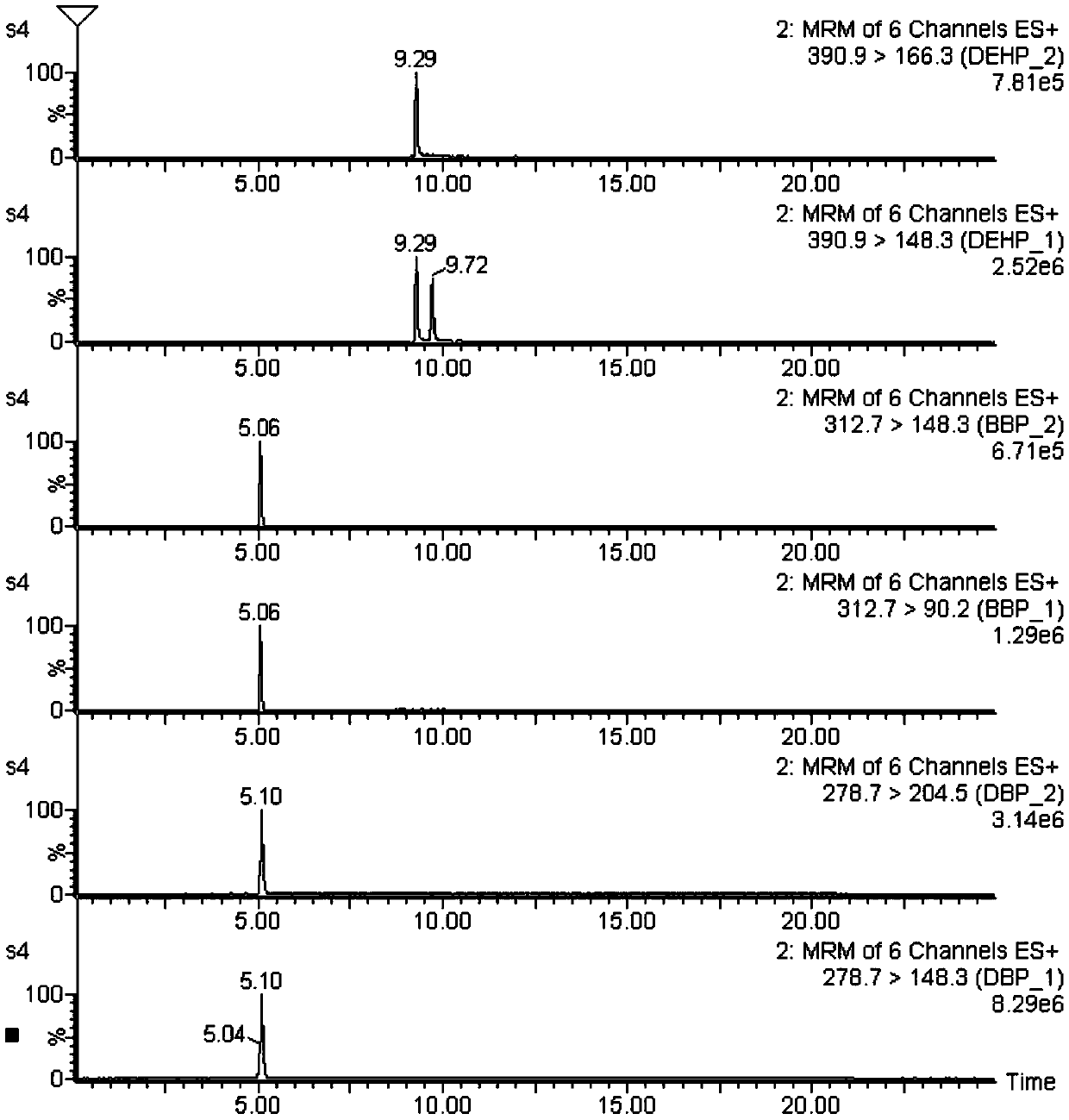

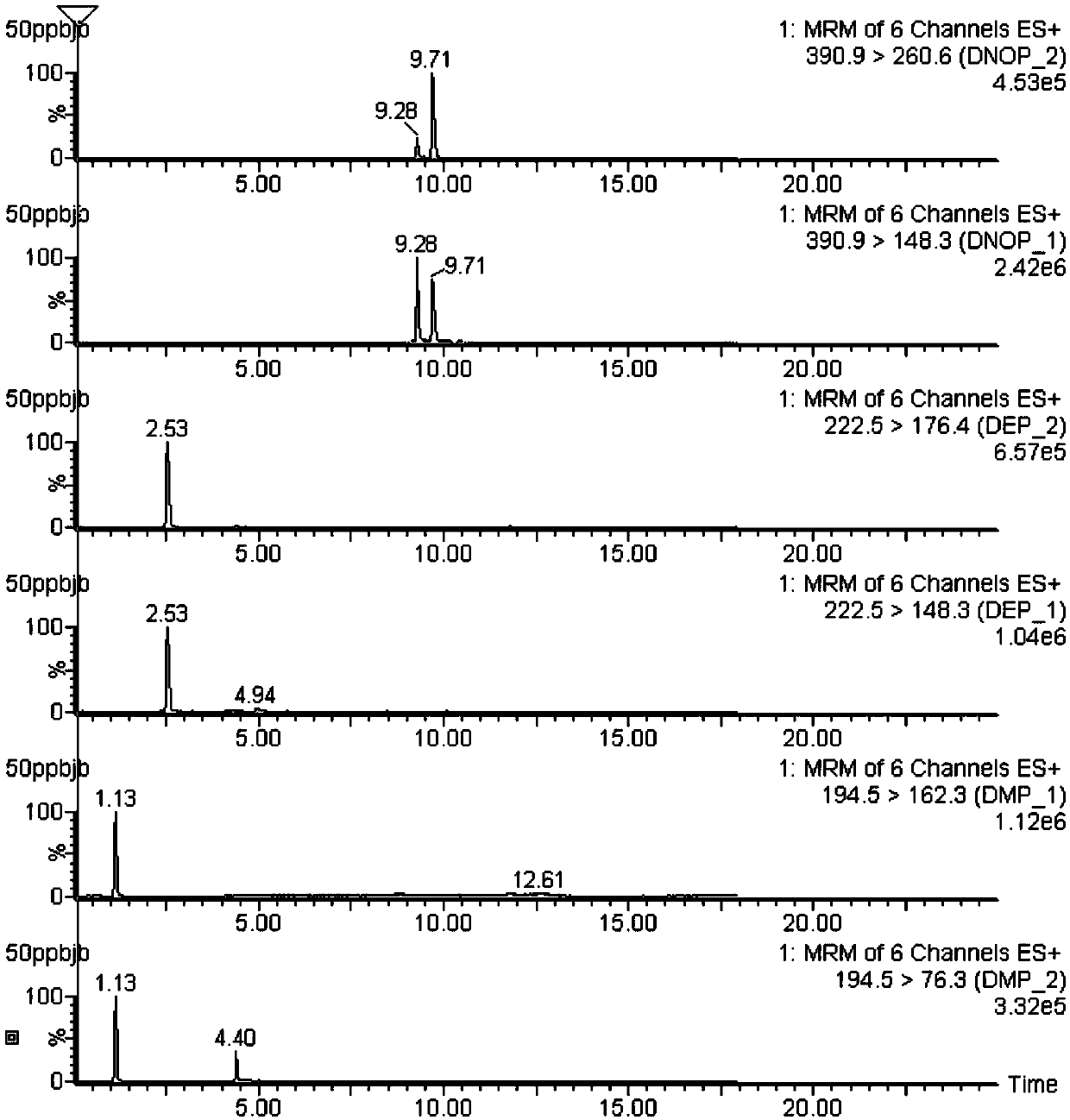

[0030] A liquid chromatography tandem mass spectrometry detection method for the determination of phthalate plasticizers in processed aquatic products, including organic extraction, chromatographic purification, detection and analysis, in which the phthalic acid in processed aquatic products is extracted through the combination of extractant and dispersant Ester plasticizer, the above dispersant is tetrabutylammonium chloride and 4-hexyl resorcinol. This method is based on ultra-high performance liquid chromatography-mass spectrometry to detect and quantitatively analyze phthalate plasticizers extracted from processed aquatic products. This method has high sensitivity, high accuracy, and high throughput, and can be used in aquatic processing. Detection of phthalate plasticizers in products.

[0031] The organic extraction steps are as follows: take the dried edible part of the aquatic product processed Antarctic krill to make meat emulsion, add the extractant and the dispersant t...

Embodiment 2

[0041] A liquid chromatography tandem mass spectrometry detection method for determining phthalate plasticizers in processed aquatic products includes the following specific steps:

[0042] 1) Organic extraction: After the dried edible part of the processed aquatic product Antarctic krill is made into meat emulsion, the extractant is 1.2 times the weight of the processed aquatic product and the dispersant is 0.18 times the weight of the processed aquatic product. The mixture is vortexed for 4 minutes, and then the power is 200W. Under the conditions of ultrasonic extraction for 8 minutes, centrifuge at a rate of 8000r / min for 5 minutes to take the supernatant. After repeated extractions twice, the extract was evaporated and concentrated to 1 / 3 times the volume at 40°C to obtain the sample solution. The agent is a dichloromethane-n-hexane (1:1) mixed solvent, and the weight ratio of tetrabutylammonium chloride and 4-hexylresorcinol in the above dispersant is 2:4.3;

[0043] 2) Chrom...

Embodiment 3

[0046] A liquid chromatography tandem mass spectrometry detection method for the determination of phthalate plasticizers in processed aquatic products. The chromatographic purification steps are optimized. The specific optimization measures are as follows: the glass is chromatographed and the weight ratio is 1:1. Packed with neutral alumina and anhydrous sodium sulfate. After rinsing with n-hexane, transfer the sample solution to the chromatography column at a flow rate of 1.5 mL / min, and then use the same amount of dichloromethane-n-hexane mixed solution and acetic acid Elute with ethyl acetate-n-hexane mixed solution at a flow rate of 2.5mL / min. Collect the sample effluent and the target eluate, rotate and evaporate at 35~45℃ to obtain the solid phase, and then dissolve it with methanol to a constant volume. 1~2mL, pass through a 0.22μm microporous membrane for use. The volume ratio of the components in the methylene chloride-n-hexane mixed solution is dichloromethane: n-hexan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com