Metal and nitrogen codoped ultrathin carbon nanosheet catalyst and preparation method and application thereof

A catalyst and co-doping technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of limiting the catalytic activity of oxygen reduction reaction and reducing the utilization rate of active sites, so as to achieve excellent catalytic performance, improve utilization rate, To achieve the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

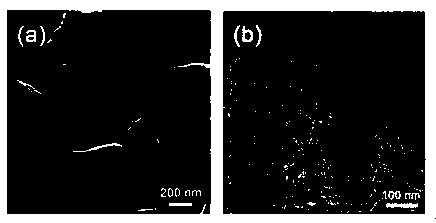

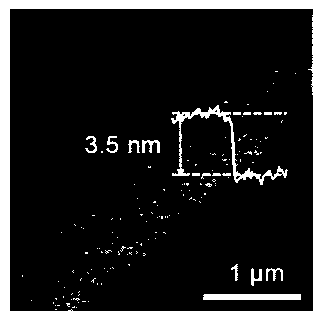

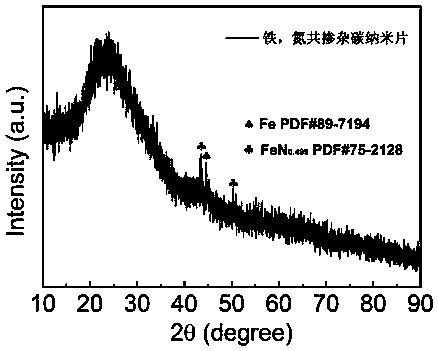

[0034] Preparation of iron, nitrogen co-doped ultra-thin carbon nanosheet catalyst, the steps are as follows:

[0035] (1) Add 121 mg of Tris to 100 mL of deionized water to obtain 0.01 mol L -1 buffer solution, pH 7.4, add 100 mg tetracarboxyphenyl porphyrin iron, ultrasonic 30 min, stir until completely dissolved, add 10 g potassium chloride to the above solution, stir until completely dissolved.

[0036] (2) The solution was placed in a lyophilizer, frozen at -50 °C for 6 h, and then lyophilized in a vacuum environment for 48 h.

[0037] (3) The freeze-dried product was placed in a tube furnace for carbonization under an Ar atmosphere with a heating rate of 5 °C min -1 , the holding temperature was 800 °C, and the holding time was 2 h. After cooling to room temperature, it was washed with deionized water to remove potassium chloride.

[0038] (4) The product was placed in a tube furnace, in NH 3 Heat treatment was carried out under atmosphere at a heating rate of 5 °C mi...

Embodiment 2

[0041] The preparation process of Example 1 is adopted, except that the inorganic salt used is replaced by potassium bromide or potassium sulfate. After freeze-drying, the mixture of inorganic salt and porphyrin iron still maintains a two-dimensional sheet structure, such as Figure 5 shown. It shows that the method has wide applicability for different inorganic salts.

Embodiment 3

[0043] Adopt the preparation process of embodiment 1, its difference is that the addition of potassium chloride is reduced to 5 g, and the catalyst specific surface area of making is about 400 m 2 g -1 , the morphology basically maintains a sheet-like structure, and its SEM image is shown in Figure 6 , indicating that changing the amount of potassium chloride added will affect the pore structure on the basis of maintaining the sheet structure, thereby changing the specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com