Photothermal Seawater Desalination Membrane with Metal Organic Framework

A metal-organic framework and photothermal technology, applied in the field of solar seawater desalination, can solve environmental pollution and other problems, and achieve the effects of high thermal conductivity, low production cost, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

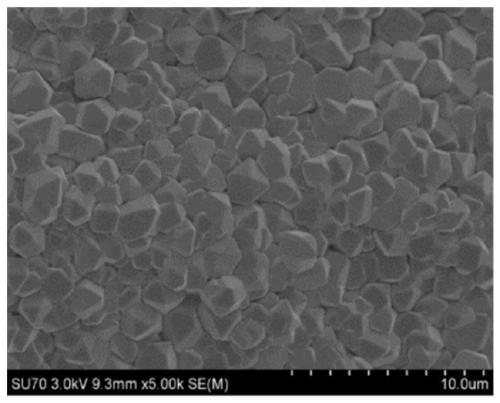

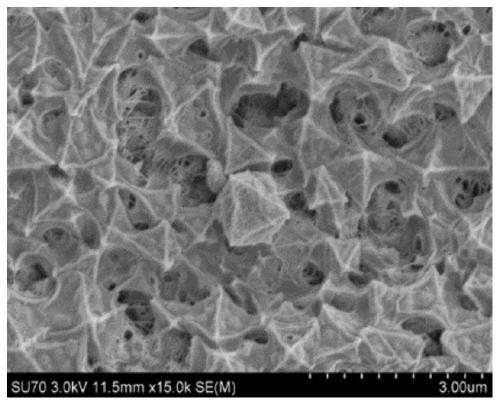

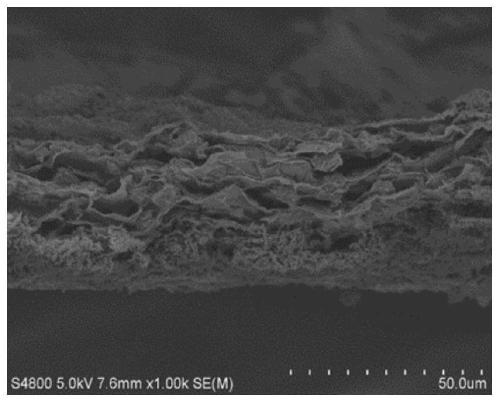

Image

Examples

Embodiment 1

[0064] 1) 400ml copper hydroxide nanowire solution was mixed with 1.07ml concentration of 0.75mg / L single-walled carbon nanotube aqueous solution and 0.76ml concentration of 0.03wt% sodium polystyrene sulfonate solution, and after magnetic stirring for 10 minutes, Vacuum filtration on the polycarbonate porous membrane, after the polycarbonate porous membrane is peeled off with an ethanol solution, a self-supporting composite membrane of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate is obtained, The polycarbonate porous membrane has a diameter of 4.7 cm and a pore size of 1 micron.

[0065] 2) Put the composite film of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate into 20ml concentration of 10mM trimesic acid solution (the volume of ethanol and water is 1:1) , reacted at room temperature for 12 hours.

[0066] After the reaction, wash 3 times with the mixed solvent of the ...

Embodiment 2

[0069] 1) 400ml copper hydroxide nanowire solution was mixed with 1.42ml concentration of 0.75mg / L single-walled carbon nanotube aqueous solution and 0.76ml concentration of 0.03wt% sodium polystyrene sulfonate solution, and after magnetic stirring for 10 minutes, Vacuum filtration on the polycarbonate porous membrane, after the polycarbonate porous membrane is peeled off with an ethanol solution, a self-supporting composite membrane of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate is obtained, The polycarbonate porous membrane has a diameter of 4.7 cm and a pore size of 1 micron.

[0070] 2) Put the composite film of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate into 20ml concentration of 10mM trimesic acid solution (the volume of ethanol and water is 1:1) , reacted at room temperature for 12 hours.

[0071] After the reaction, wash 3 times with the mixed solvent of the ...

Embodiment 3

[0074] 1) 400ml copper hydroxide nanowire solution was mixed with 2.13ml concentration of 0.75mg / L single-walled carbon nanotube aqueous solution and 0.76ml concentration of 0.03wt% sodium polystyrene sulfonate solution, and after magnetic stirring for 10 minutes, Vacuum filtration on the polycarbonate porous membrane, after the polycarbonate porous membrane is peeled off with an ethanol solution, a self-supporting composite membrane of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate is obtained, The polycarbonate porous membrane has a diameter of 4.7 cm and a pore size of 1 micron.

[0075] 2) Put the composite film of copper hydroxide nanowires / single-walled carbon nanotubes modified by sodium polystyrene sulfonate into 20ml concentration of 10mM trimesic acid solution (the volume of ethanol and water is 1:1) , reacted at room temperature for 12 hours.

[0076] After the reaction, wash 3 times with the mixed solvent of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com