Method and system for recovering magnesium salt from desulfurization wastewater

A technology for desulfurization wastewater and magnesium salts, applied in magnesium sulfate and other directions, can solve the problems of rapid electrode consumption, impure crystalline salt, pollution of ultrafiltration and nanofiltration systems, etc., to achieve simple pretreatment, advanced process technology, and shortened process route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

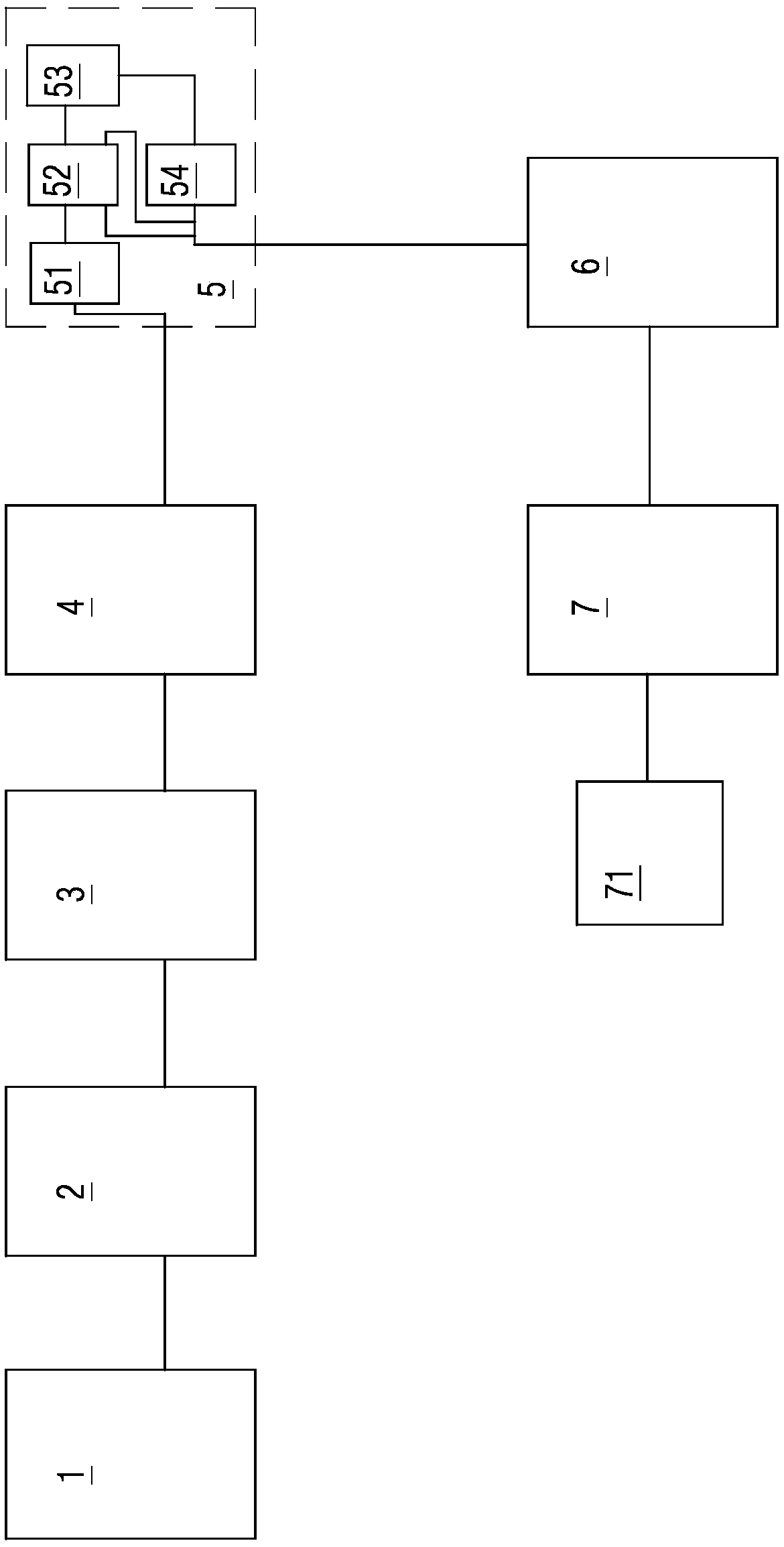

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0028] The invention aims at desulfurization waste water with high magnesium content, and provides a zero-discharge technology and method for recovering magnesium resource waste water with advanced technology, simple pretreatment and shortened overall process route.

[0029] A kind of method that magnesium salt is reclaimed from desulfurization waste water provided by the present invention, it comprises the steps:

[0030] Step A is to remove heavy metals from the desulfurization wastewater. This process step technology is relatively mature. For example, a commonly used triple box pretreatment process can be used. For details, please refer to the detailed description of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com