Preparation method of major yolk proteins of sea urchins

A technology of yolk protein and sea urchin eggs, which is applied in the field of preparation of main yolk protein of sea urchins, can solve the problems of single processed products and low high-value utilization, and achieve high productivity, improved processing utilization, and simple and effective preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1. Sea urchin egg yolk degreasing treatment: under the condition of 4°C, crack the shell of Dalian purple sea urchin, take the egg yolk, and homogenize the egg yolk homogenate to a yolk homogenate without particles. The ratio of n-hexane / absolute ethanol mixture (V 正己烷 :V 乙醇 =3:1) mixed, magnetically stirred for 6h, removed the organic reagent by suction filtration, and obtained a filter cake; the gained filter cake was mixed with n-hexane / dehydrated ethanol mixed solution (V 正己烷 :V 乙醇 = 3:1) mixed, magnetically stirred for 6 hours, and suction filtered to remove the organic reagent to obtain a filter cake; the resulting filter cake was washed with n-hexane / absolute ethanol mixture, dispersed, placed in normal temperature and naturally air-dried to obtain Dalian Purple Sea Urchin Egg yolk defatted powder; the content of protein in the obtained Dalian purple sea urchin egg yolk defatted powder measured by Kjeldahl method is 62.24% (by dry weight);

[0036] S2. Alkali...

Embodiment 2

[0042] S1. Sea urchin egg yolk degreasing treatment: under the condition of 4°C, the yellow sea urchin was broken, the egg yolk was taken, and the egg yolk homogenate was homogenized to a yolk homogenate without particles, and the egg yolk homogenate was mixed at a ratio of 1:10 (m / v). Ratio and n-hexane / absolute ethanol mixture (V 正己烷 :V 乙醇 =3:1) mixed, magnetically stirred for 6h, removed the organic reagent by suction filtration, and obtained a filter cake; the gained filter cake was mixed with n-hexane / dehydrated ethanol mixed solution (V 正己烷 :V 乙醇 = 3:1) mixed, magnetically stirred for 6 hours, and the organic reagent was removed by suction filtration to obtain a filter cake; the resulting filter cake was washed with n-hexane / absolute ethanol mixture, dispersed, and naturally air-dried at room temperature to obtain yellow sea urchin yolk Defatting powder; adopting the Kjeldahl method to measure the protein content in the obtained yellow sea urchin egg yolk defatting pow...

Embodiment 3

[0049] S1. Sea urchin egg yolk degreasing treatment: under the condition of 4°C, break the shell of Ezoma manure sea urchin, take the egg yolk, and homogenize the egg yolk homogenate to a yolk homogenate without particles, and prepare the egg yolk homogenate at a ratio of 1:10 (m / The ratio of v) and n-hexane / absolute ethanol mixed solution (V 正己烷 :V 乙醇 =3:1) mixed, magnetically stirred for 6h, removed the organic reagent by suction filtration, and obtained a filter cake; the gained filter cake was mixed with n-hexane / dehydrated ethanol mixed solution (V 正己烷 :V 乙醇 = 3:1) mixed, magnetically stirred for 6h, and the organic reagent was removed by suction filtration to obtain a filter cake; the obtained filter cake was washed with n-hexane / absolute ethanol mixture and dispersed, and then naturally air-dried at room temperature to obtain Ezoma Dung sea urchin egg yolk defatted powder; the content of protein in the obtained Ezoma dung sea urchin egg yolk defatted powder measured ...

PUM

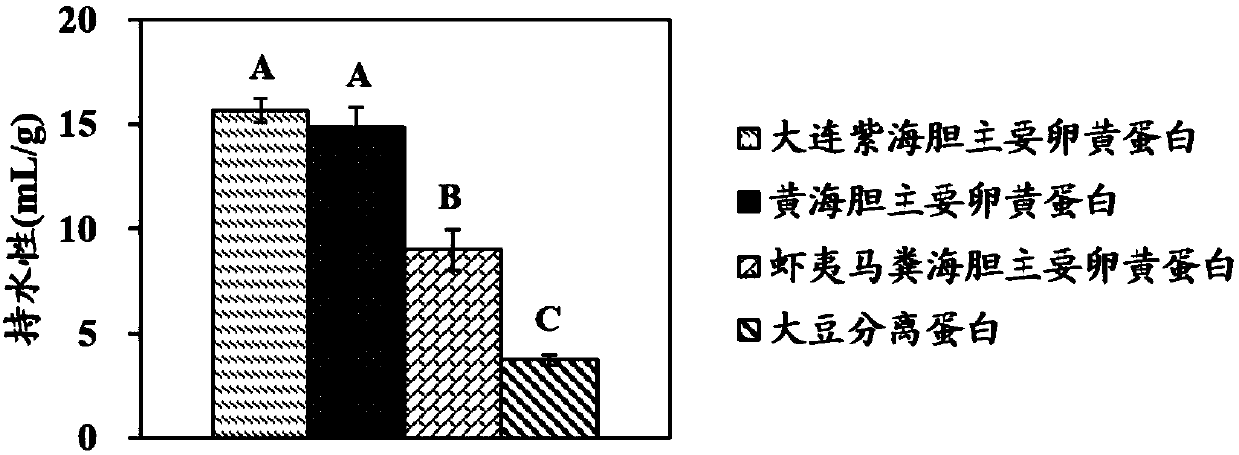

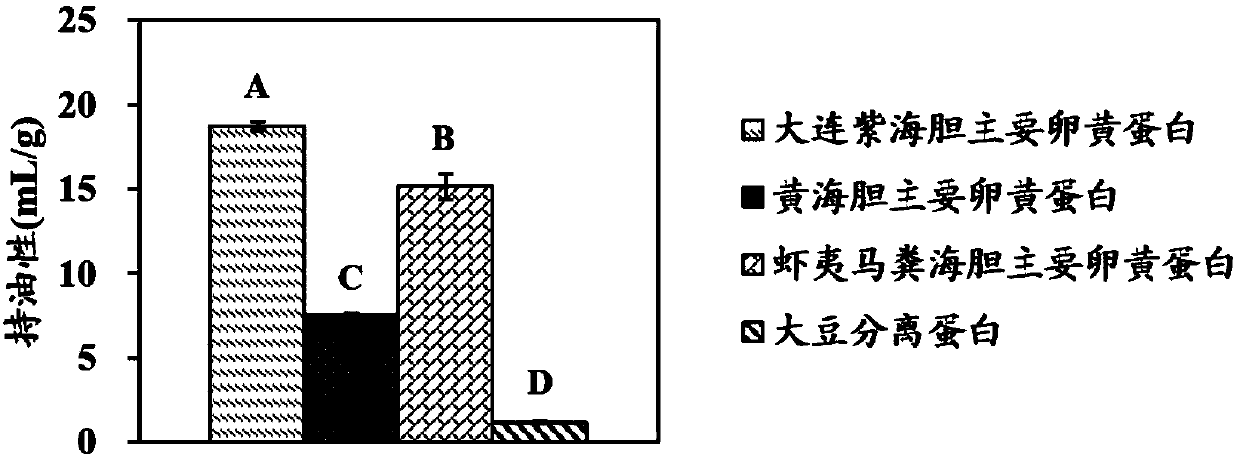

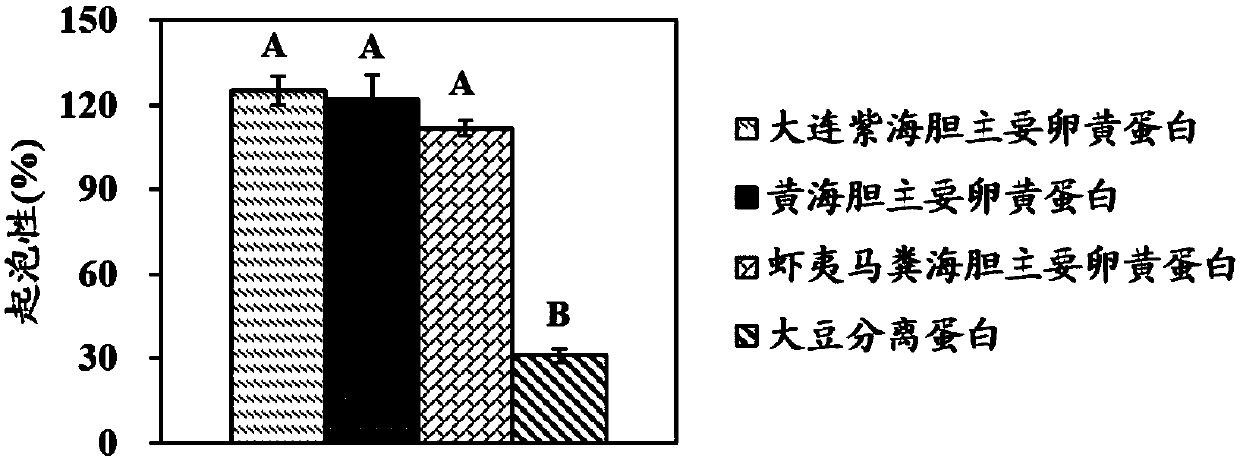

| Property | Measurement | Unit |

|---|---|---|

| water holding capacity | aaaaa | aaaaa |

| water holding capacity | aaaaa | aaaaa |

| water holding capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com