Litter for pets and preparation method thereof

A pet and mineral technology, applied in applications, animal houses, animal husbandry, etc., can solve problems affecting pets and people's living environment, and achieve the effect of reducing the probability of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

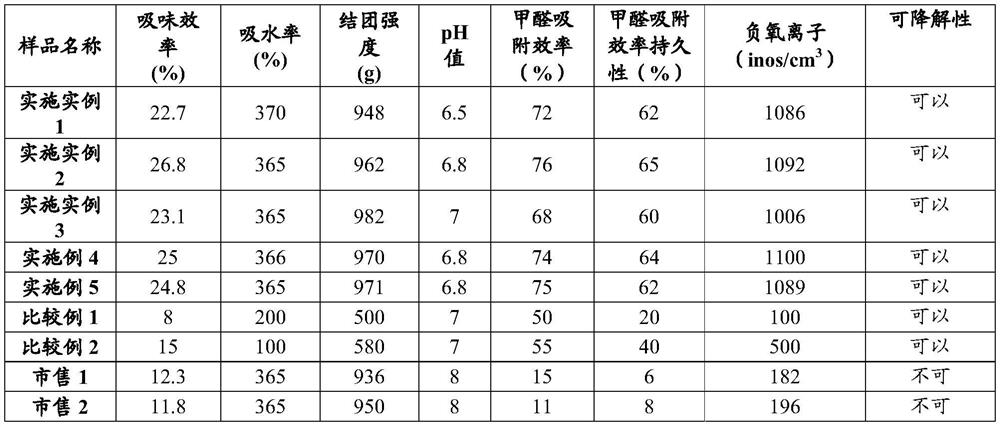

Examples

preparation example Construction

[0037] In the preparation method of the illite powder, the natural illite mineral is used as a raw material, and the powder is firstly processed through crushing and grinding. Preferably, the particle size distribution D97 of the powder is 40 μm˜500 μm.

[0038] Preferably, the mass percentage of illite in the natural illite mineral is greater than or equal to 20%.

[0039] After obtaining the powder, activate the powder at 300-500°C, preferably at 410-500°C; then, attach the solution containing lanthanide rare earth elements to the activated On the powder, illite functional powder is obtained. The solution containing lanthanide rare earth elements is attached to the surface or inside of the activated powder.

[0040] Preferably, the solution containing lanthanide rare earth elements is attached to the activated powder by spraying or spraying. The lanthanide rare earth element is one or more selected from lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadol...

Embodiment 1

[0064] The natural illite mineral, whose mineral composition is 37.8% illite, is crushed, ground, classified to D97=56 μm, and activated at 300° C. for 2 hours.

[0065] Prepare 800ml of a solution containing rare earth elements scandium, yttrium, lanthanum, cerium, praseodymium and neodymium with a concentration of 10mg / ml, 400ml of a solution with a concentration of 10mg / ml containing samarium, europium and gadolinium, and 100ml of a solution with a concentration of 10mg / ml. ml solution containing rare earth element terbium.

[0066] The above solution is sprayed into the activated illite powder, and stirred, so that the rare earth element is coated on the surface of the illite powder, and the illite functional powder is obtained.

[0067] Bentonite ore (montmorillonite content is 68%) is crushed and ground to obtain bentonite powder;

[0068] Sodium carbide was added to the bentonite powder, stirred evenly, and sodiumized for 48 hours to obtain sodium bentonite; the mass o...

Embodiment 2

[0071] The natural illite mineral, whose mineral composition is 35% illite, is crushed, ground, classified to D97=100 μm, and activated at 350° C. for 1.5 hours.

[0072] Prepare 400 ml of a solution containing rare earth elements samarium, europium and gadolinium with a concentration of 10 mg / ml.

[0073] The above solution is sprayed into the activated illite powder, and stirred, so that the rare earth element is coated on the surface of the illite powder, and the illite functional powder is obtained.

[0074] Bentonite ore (montmorillonite content is 60%) is crushed and ground to obtain bentonite powder;

[0075] Add sodium chloride to the bentonite powder, stir evenly, and sodiumize for 55 hours to obtain sodium bentonite; the quality of the sodium carbide is 0.2% of the mass of the bentonite powder.

[0076] Get 45 parts of illite functional powder, diatomaceous earth (SiO 2 The content is 60.2%) 8 parts, 40 parts of sodium bentonite, 12 parts of water, fully stir in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com