Metal oxide-sulfide composite oxygen evolution electrocatalyst, preparation method and applications thereof

A technology of electrocatalysts and oxides, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low activity, high cost and poor stability of oxygen evolution electrocatalysts, and achieve catalytic activity High, the synthesis method is simple and controllable, and the effect of reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of metal oxide-sulfide composite oxygen evolution electrocatalyst of the present invention

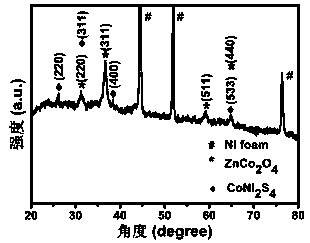

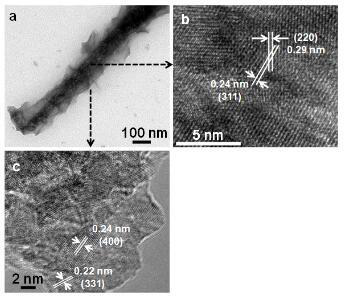

[0059] (1) Prepare 30 mL of a mixed aqueous solution of 0.02 mol / L zinc nitrate, 0.04 mol / L cobalt nitrate, 0.04 mol / L ammonium fluoride and 0.1 mol / L urea, transfer it to a 40 mL Teflon-lined In the stainless steel hydrothermal reaction kettle, add a piece of clean nickel foam, the area of the foam nickel is 4 cm 2 . The hydrothermal reaction kettle was placed in an oven and heated at 120° C. for 5 hours. The nickel foam with the precursor was taken out, washed and dried, and then heat-treated at 400° C. for 2 hours in the air to obtain the nickel foam with zinc cobaltate nanowires grown.

[0060] (2) In a three-electrode system, nickel-cobalt sulfide nanosheets were electrochemically deposited by cyclic voltammetry: nickel foam with zinc cobaltate nanowires was used as the working electrode, graphite rods were used as auxiliary electrodes, and silver / silver ...

Embodiment 2

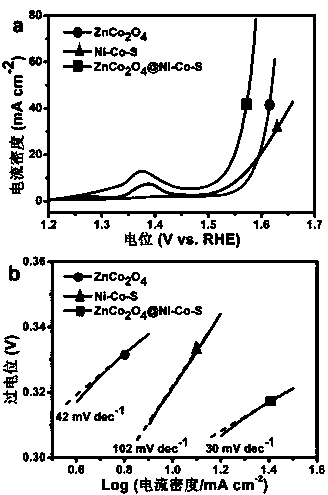

[0075] The preparation method is basically the same as in Example 1, except that the number of turns of the electrochemically deposited nickel-cobalt sulfide nanosheets is changed from 15 turns to 20 turns, and the composition of the obtained composite catalyst is basically the same as that in the example. at 10mA / cm 2 The overpotential required to measure the oxygen evolution reaction at a current density of 320 mV is 320 mV.

Embodiment 3

[0077] The preparation method is basically the same as in Example 1, except that the number of turns of the electrochemically deposited nickel-cobalt sulfide nanosheets is changed from 15 turns to 10 turns, and the composition of the obtained composite catalyst is basically the same as that in the example. at 10mA / cm 2 The overpotential required to measure the oxygen evolution reaction at a current density of 335 mV is 335 mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com