Steel/polyurethane sandwich board and preparation method and application thereof

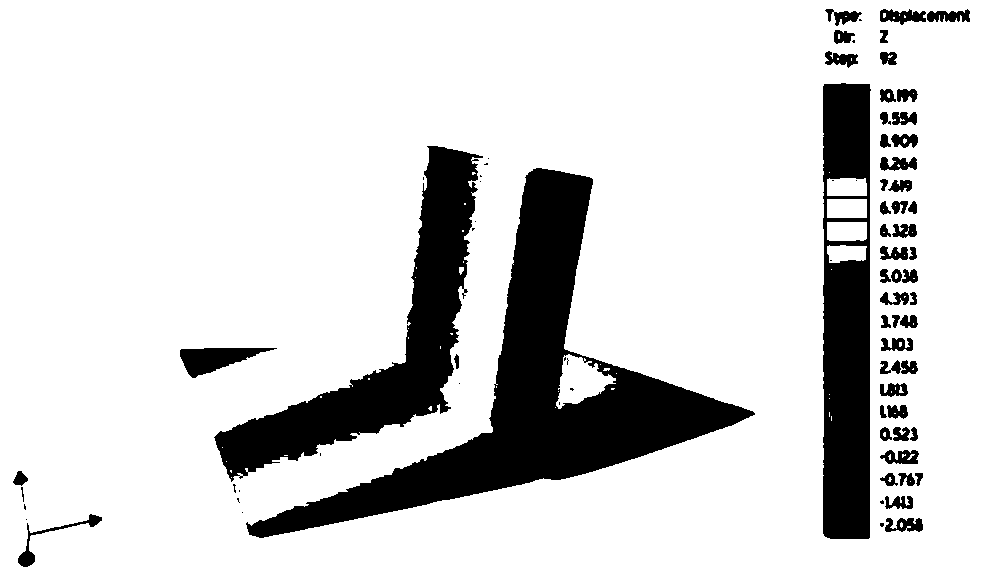

A technology of polyurethane and sandwich panels, applied in chemical instruments and methods, lamination, layered products, etc., can solve the complex preparation process, process problems have not been properly solved, and steel/polyurethane sandwich panels rarely have engineering fields, etc. problems, achieve high quality, optimize the production line, and avoid irregular deformation of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The polyurethane core material includes by mass fraction: hard segment material diphenylmethane diisocyanate 30%, soft segment material polypropylene diol with a molecular weight of 400 62.7%, chain extender 1,4-butanediol 2%, catalyst dibutyltin diol Laurate 0.3% and curing agent 3,3'-dichloro-4,4'-diaminodiphenylmethane 5%.

[0032] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0033] (1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and 3,3'-dichloro-4,4'-diaminodiphenylmethane into the barrel of casting machine B, and mix at normal temperature and pressure to obtain a polyurethane core material;

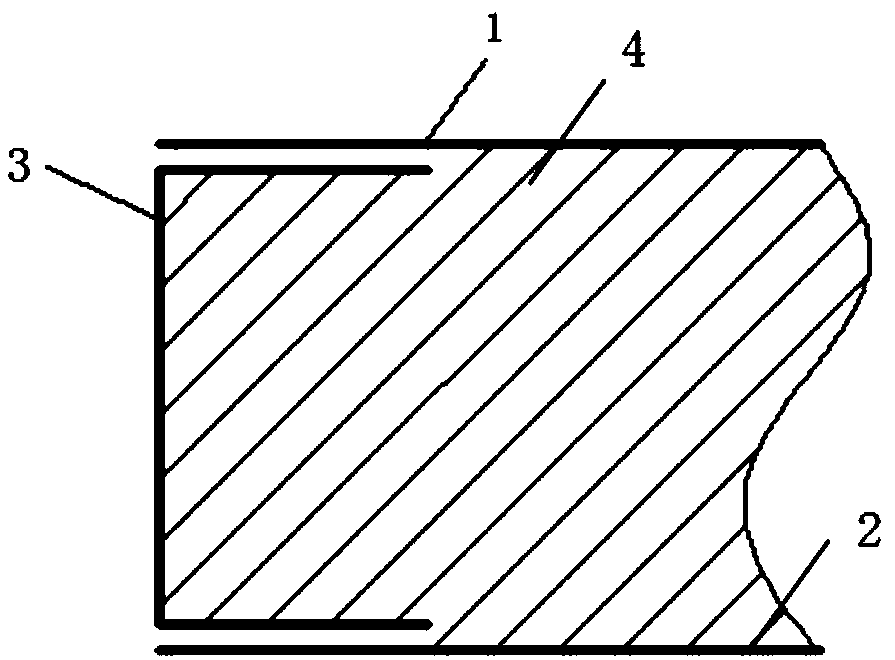

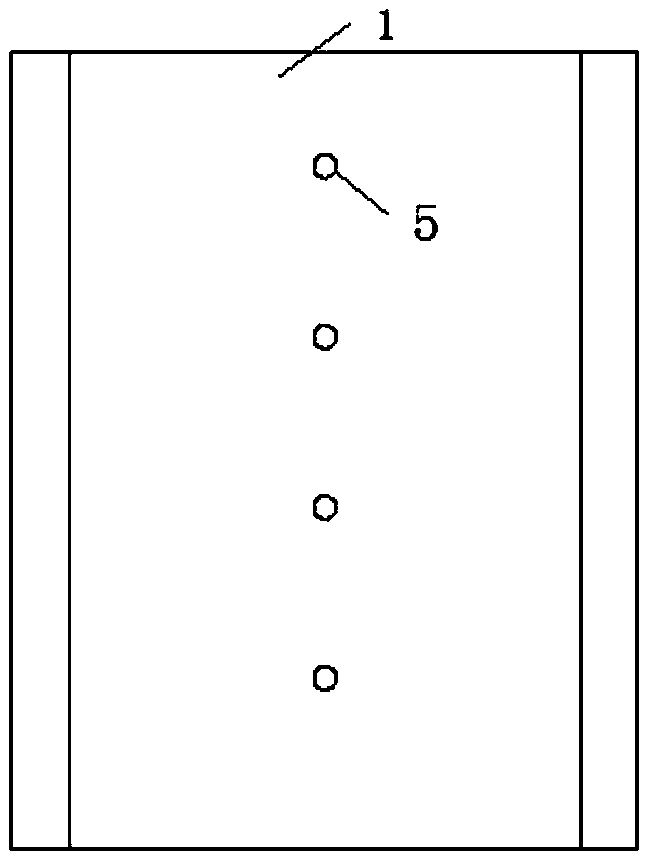

[0034] (2) Cavity preparation: first, the upper and lower steel pan...

Embodiment 2

[0038] The polyurethane core material includes: 20% diphenylmethane diisocyanate as a hard segment material, 77.4% polypropylene glycol with a molecular weight of 400 as a soft segment material, 0.5% chain extender 1,4-butanediol, and dibutyltin diol as a catalyst. Laurate 0.1% and curing agent dimethylthiotoluenediamine 2%.

[0039] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0040](1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and dimethylthiotoluenediamine into the B barrel of the pouring machine, and mix at normal temperature and pressure to obtain a polyurethane core material;

[0041] (2) Cavity preparation: first, the upper and lower steel panels are treated, that...

Embodiment 3

[0045] The polyurethane core material includes by mass fraction: hard segment material diphenylmethane diisocyanate 50%, soft segment material polypropylene diol with a molecular weight of 400 47.4%, chain extender 1,4-butanediol 0.5%, catalyst dibutyltin diol Laurate 0.1% and curing agent dimethylthiotoluenediamine 2%.

[0046] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0047] (1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and dimethylthiotoluenediamine into the B barrel of the pouring machine, and mix at normal temperature and pressure to obtain a polyurethane core material;

[0048] (2) Cavity preparation: firstly, the upper steel panel and the lower steel panel are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com