Device and method for short-cut nitrification of swine farm biogas slurry in artificial wetland based on zeolite filler

A technology of artificial wetland and short-range nitrification, which is applied in chemical instruments and methods, sustainable biological treatment, animal husbandry wastewater treatment, etc., can solve the problem of low hydraulic load of nitrite nitrogen, and achieve increased hydraulic load, stable short-range nitrification, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

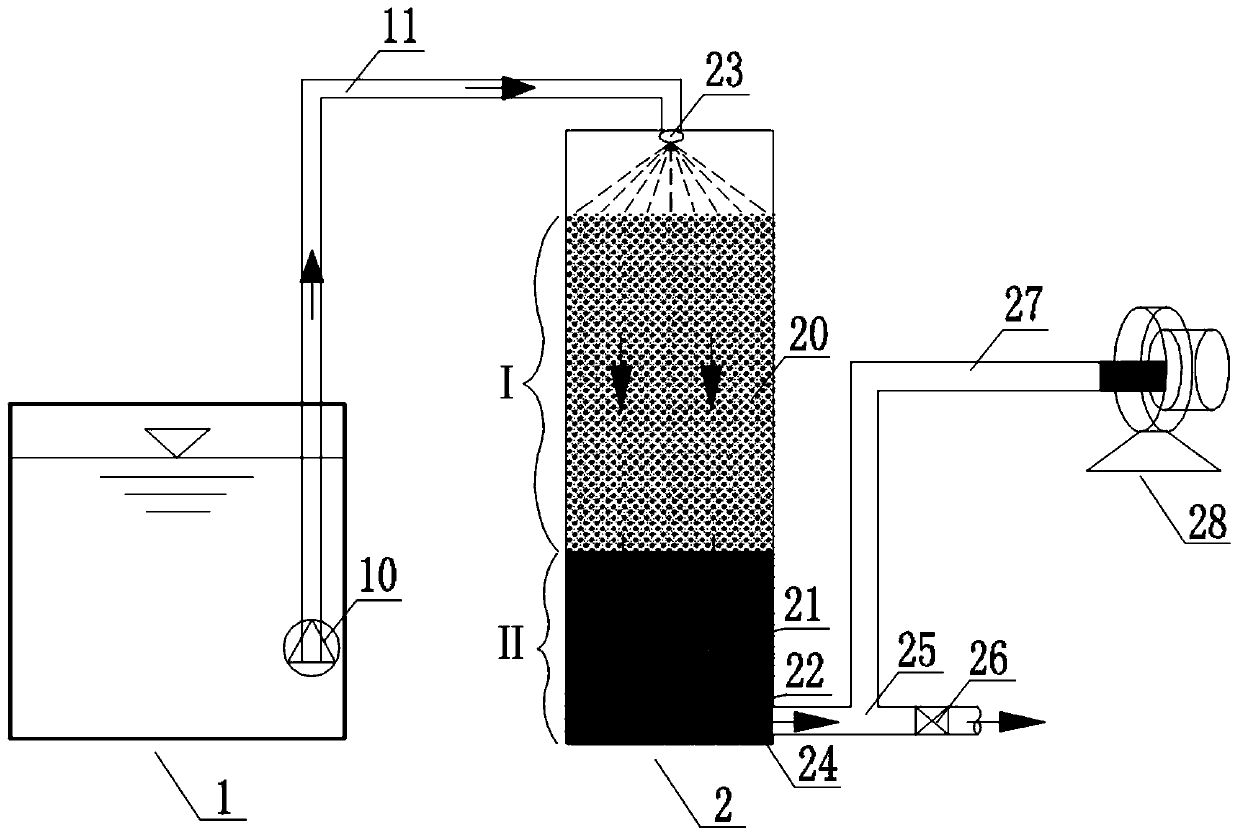

[0044] The hydraulic load of this embodiment is 0.64m 3 / (m 2 d). The structure of the device is as figure 1 shown. In this embodiment, the heights of wetland I and wetland II are 1.40m and 0.20m respectively, and the height ratio is 7:1. The water distribution device 23 sprays the waste water evenly on the surface of the wetland I, and the percolated waste water enters the wetland II. Because the electric valve 26 is closed, the water level in the wetland II keeps rising. When the water inflow ends, the water level rises to the interface between Wetland I and Wetland II. A drainage-ventilation pipe 24 is arranged in the gravel layer 22 for discharging the treated waste water out of the system and supplying the system with ventilation and oxygen when it dries up. Drainage-ventilation pipe 24 is equipped with tee 25 at the outer part of the pond, and its two ends are connected air inlet pipe 27 and electric valve 26 respectively. The equipment is controlled by a time con...

Embodiment 2

[0050] The hydraulic load of this embodiment is 0.64m 3 / (m 2 d), the same as in Example 1. The structure of the device is as figure 1 shown. The arrangement sequence of the filler layers in this embodiment is exactly the same as that in Embodiment 1, the main difference is that the first zeolite functional layer 20 and the second zeolite functional layer 21 are filled with mixed fillers of zeolite and crushed stone, and the volume ratio of zeolite to crushed stone is 1.5:1.

[0051] The test also used biogas slurry from a pig farm as raw water. The specific water quality is as follows: pH is 7.35-7.77, COD is 725-1100mg / L, ammonia nitrogen is 680-1232mg / L, nitrate nitrogen is <1mg / L, nitrite state Nitrogen is <1mg / L.

[0052] After the system runs stably, the water quality after treatment by the new constructed wetland device is as follows: pH is 6.27-7.51, COD is 362-930mg / L, ammonia nitrogen is 221-473mg / L, nitrite nitrogen is 432-642mg / L, nitrate Nitrogen is 3-46mg / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com