Development and application of Nisin solid stabilizer

A stable solid and wet solid technology, applied in the fields of application, peptide, organic chemistry, etc., can solve the problem of high production cost, achieve the effect of long stability, good repeatability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

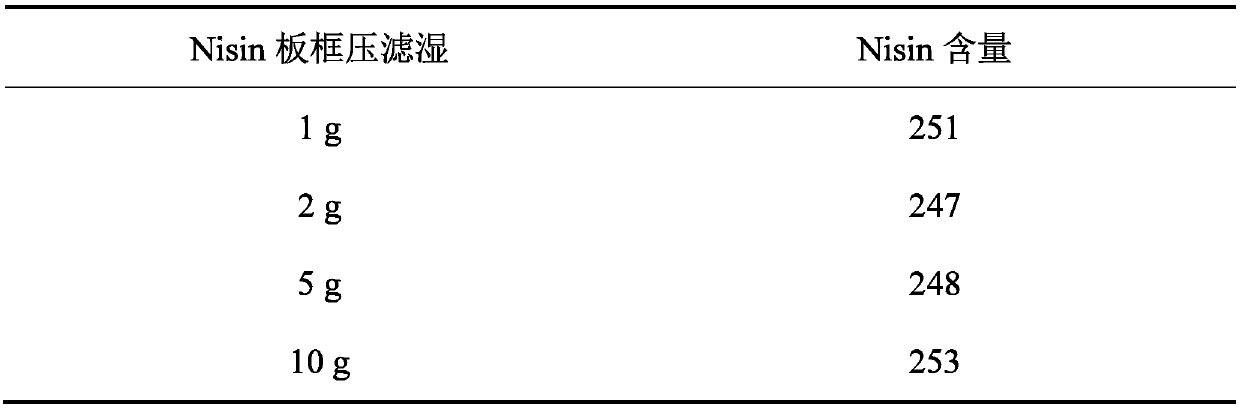

[0024] 3 tons of Nisin fermentation broth, sterilized by ceramic membrane filtration, the obtained supernatant was concentrated 10 times with an ultrafiltration membrane greater than 1000 Daltons, 60kg of NaCl was added to the 300L concentrated solution for salting out, and 80kg was obtained by plate and frame pressure filtration of wet solids. Take 1g, 2g, 5g, and 10g of Nisin plate and frame filter wet solids respectively, and measure the content of Nisin. The determination methods are all determined by the biological potency method, and the operation is performed according to the national standard NY / T392-2000. The results are shown in Table 1.

[0025] Table 1 The content of Nisin in the wet solid of Nisin plate and frame press (mg / g)

[0026]

[0027] The results in Table 1 show that the content of Nisin in the Nisin plate and frame filter wet solid is about 250mg / g.

Embodiment 2

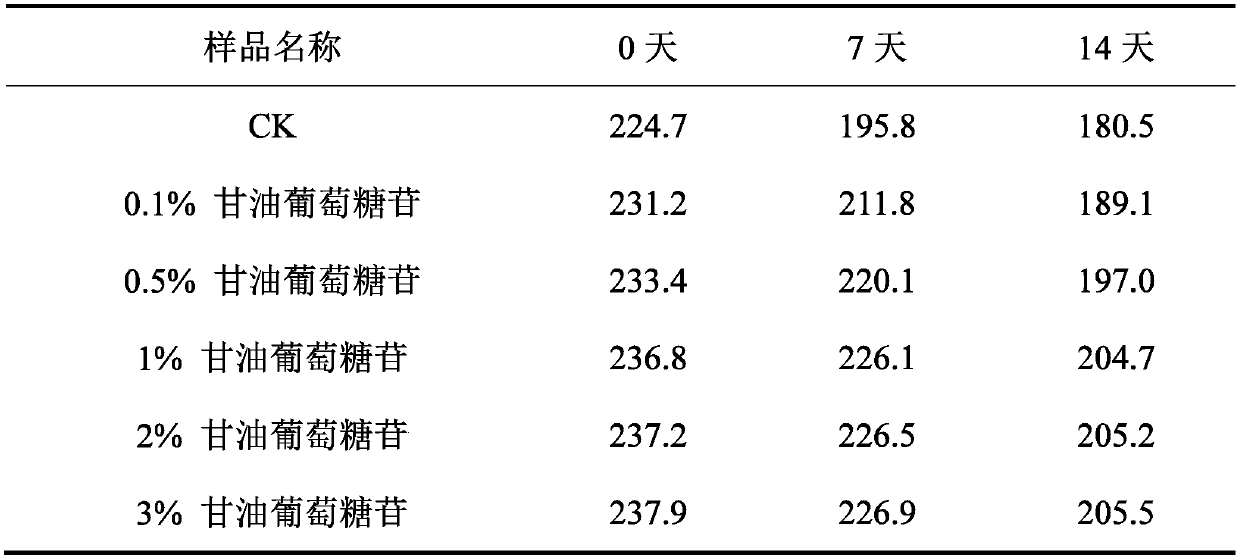

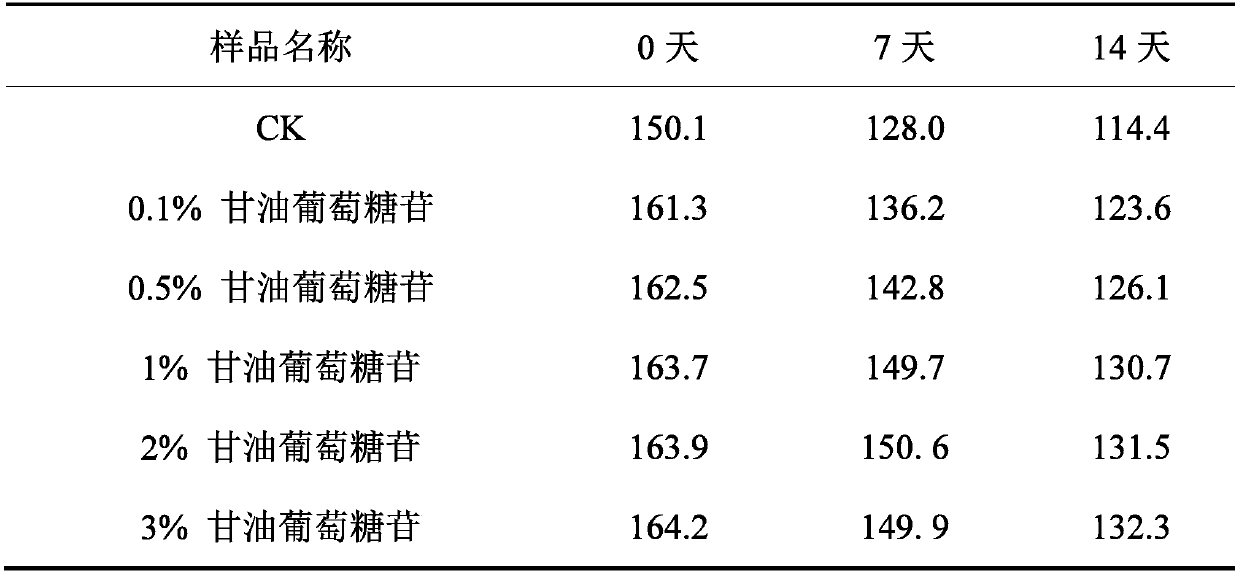

[0029] Accurately weigh 1.5kg Nisin plate and frame press filter wet powder and 1.0kg NaCl, add 0.1%, 0.5%, 1%, 2%, 3% glycerol glucoside, dissolve in 10.0L aqueous solution, stir at room temperature for 15min, then add concentrated Hydrochloric acid to adjust the pH to 2.9, after stirring evenly. Take 5L of Nisin solution for spray drying of Nisin products, the inlet temperature is 180°C, the outlet temperature is 80°C, and blank control test is carried out at the same time.

[0030] In addition, 5L of Nisin solution was taken to vacuum-dry Nisin products. During the vacuum drying process, keep at 40°C for 4h and at 55°C for 4h to obtain a dry sample, which was ground and pulverized for content determination. The product obtained by spray drying and vacuum drying was subjected to a storage test at 55° C., and sampling and analysis were carried out at 7 days and 14 days respectively. The content of Nisin was determined by the biological potency method, and the determination m...

Embodiment 3

[0038] Accurately weigh 1.5kg Nisin plate and frame press filter wet powder and 1.0kg NaCl, add 0.1%, 1%, 2% low-ester pectin, methionine and chitosan, dissolve in 10.0L aqueous solution, stir at room temperature 15min, then add concentrated hydrochloric acid to adjust the pH to 2.9, and stir well. Take 5L of Nisin solution for spray drying of Nisin products, the inlet temperature is 180°C, the outlet temperature is 80°C, and blank control test is carried out at the same time.

[0039] In addition, 5L of Nisin solution was taken to vacuum-dry Nisin products. During the vacuum drying process, keep at 40°C for 4h and at 55°C for 4h to obtain a dry sample, which was ground and pulverized for content determination. The product obtained by spray drying and vacuum drying was subjected to a storage test at 55° C., and sampling and analysis were carried out at 7 days and 14 days respectively. The content of Nisin was determined by the biological potency method, and the determination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com