Organic barrier film, preparation method of organic barrier film and quantum dot device

A technology of barrier film and quantum dot layer, which is applied in the fields of organic barrier film, preparation of organic barrier film, and quantum dot devices, can solve problems such as cracking of inorganic oxide layer, loss of barrier performance, complex process, etc., to improve adhesion, Reduce water vapor, reduce the effect of water vapor penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing an organic barrier film, comprising the following steps:

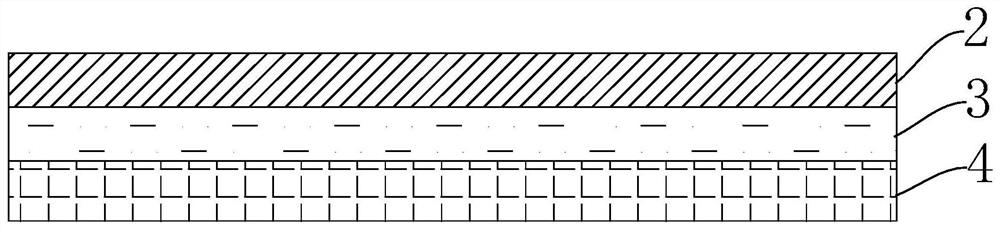

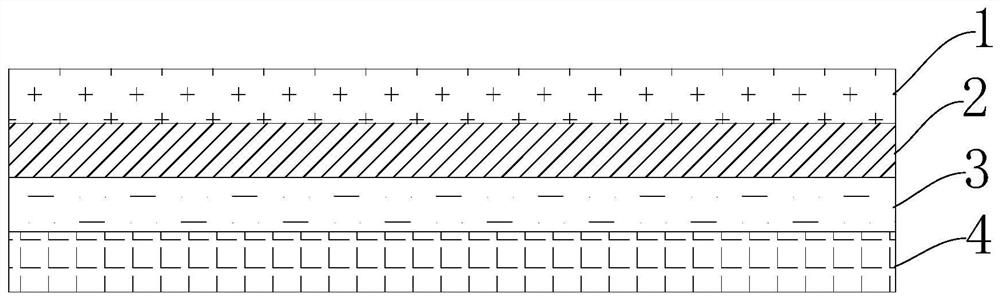

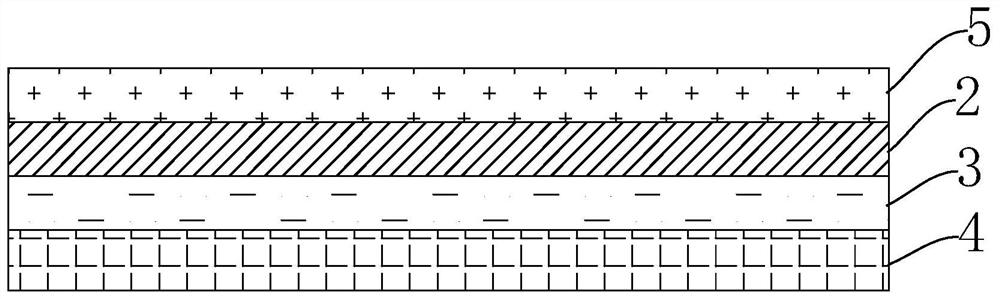

[0043] providing a substrate layer 2;

[0044] An adhesive layer 3 is arranged on the second side of the substrate layer 2, and an oxygen barrier layer 4 is arranged on the adhesive layer 3. The oxygen barrier layer 4 includes polyvinyl alcohol, and a chemical interaction is formed between the adhesive layer 3 and the oxygen barrier layer 4. couplet.

[0045] In some embodiments, the preparation method of the adhesive layer 3 includes: disposing a mixture including a polymer adhesive, a cross-linking agent, and a chelating agent on the second side of the substrate layer 2 .

[0046] In some embodiments, the above-mentioned polymer binder is selected from one or more of polyester, polyurethane, and polyacrylate, and the above-mentioned polymer binder includes at least one of the following groups: hydroxyl, carboxyl, Amino groups, chelating agents and po...

Embodiment 1

[0056] Add acrylic acid, butyl acrylate, hydroxyethyl acrylate and quantitative deionized water into a three-neck flask with a stirring and condensing reflux tube, pass nitrogen gas for 10 minutes, stir and raise the temperature to 75°C, add quantitative potassium persulfate aqueous solution, and keep warm for 8 hours , cooled to 30°C and discharged, measured the solid content, and then added 0.2% leveling agent, 0.1% defoamer, 0.5% polycarbodiimide and 3% boric acid to obtain an acrylate adhesive emulsion .

[0057] Apply the above acrylate adhesive emulsion on one side of the PET substrate with a thickness of 100 μm, bake and cure at 120°C for 3 minutes to form a bonding layer with a thickness of 1 μm, and then coat the bonding layer with a layer of the aforementioned oxygen barrier Layer raw materials, bake and cure at 120°C for 3 minutes to form an oxygen barrier layer with a thickness of 5 μm. The organic barrier film was obtained, and its oxygen transmission rate was me...

Embodiment 2

[0060] Add dehydrated polyethylene adipate and dicyclohexylmethane diisocyanate into a three-necked flask with a stirring and condensing reflux tube, blow nitrogen for 10 minutes, stir and heat up to 65°C, add dibutyltin dilaurate catalyst , keep warm for 15min, then raise the temperature to 85°C, keep warm for 1h, add dimethylolpropionic acid, keep warm for 1h, cool down to 50°C, add triethylamine to the system, react for 30min, then take an appropriate amount of deionized water at room temperature at 3000rpm Stir and emulsify for 1 hour to obtain a uniform blue-white emulsion, then add 0.1% by mass of an antifoaming agent, 0.3% of aziridine and 1% of boric acid to obtain a polyurethane adhesive emulsion.

[0061] Apply the above-mentioned polyurethane adhesive emulsion on one side of the PET substrate with a thickness of 100 μm, bake and cure at 120°C for 3 minutes to form an adhesive layer with a thickness of 1 μm, and then coat the aforementioned oxygen barrier layer on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com