Mesoporous platinum nickel phosphorus nanocage electrocatalyst and preparation method thereof

An electrocatalyst and nanocage technology, which is applied in the field of mesoporous platinum-nickel-phosphorus nanocage electrocatalyst and its preparation, can solve problems such as the difficulty of three-dimensional platinum-nickel-phosphorus nanostructures, and achieve simple synthesis methods, reduced usage, and high product yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

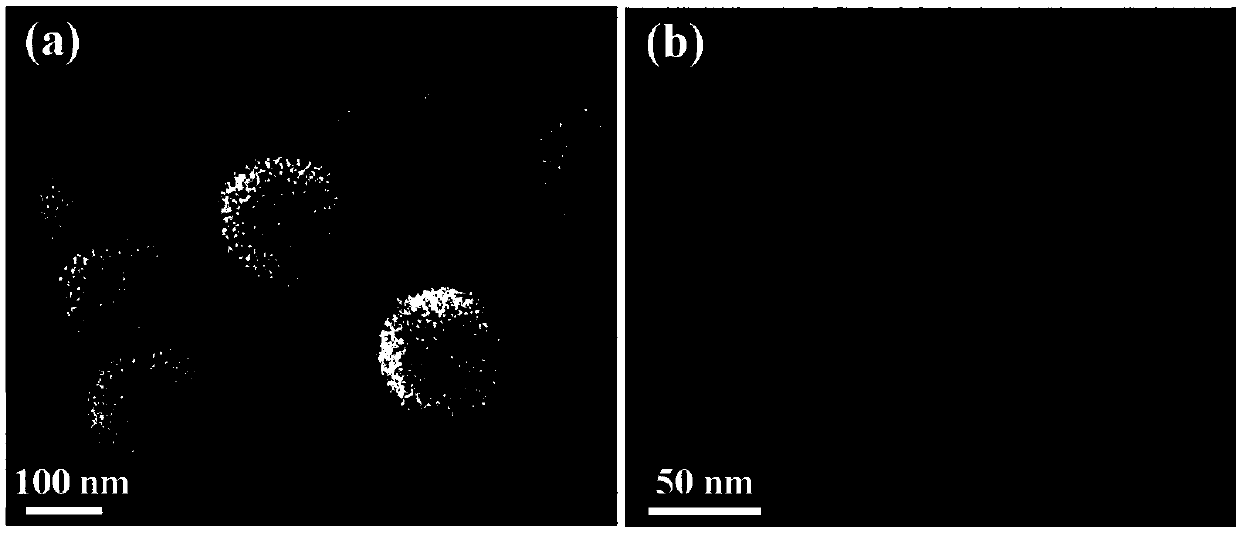

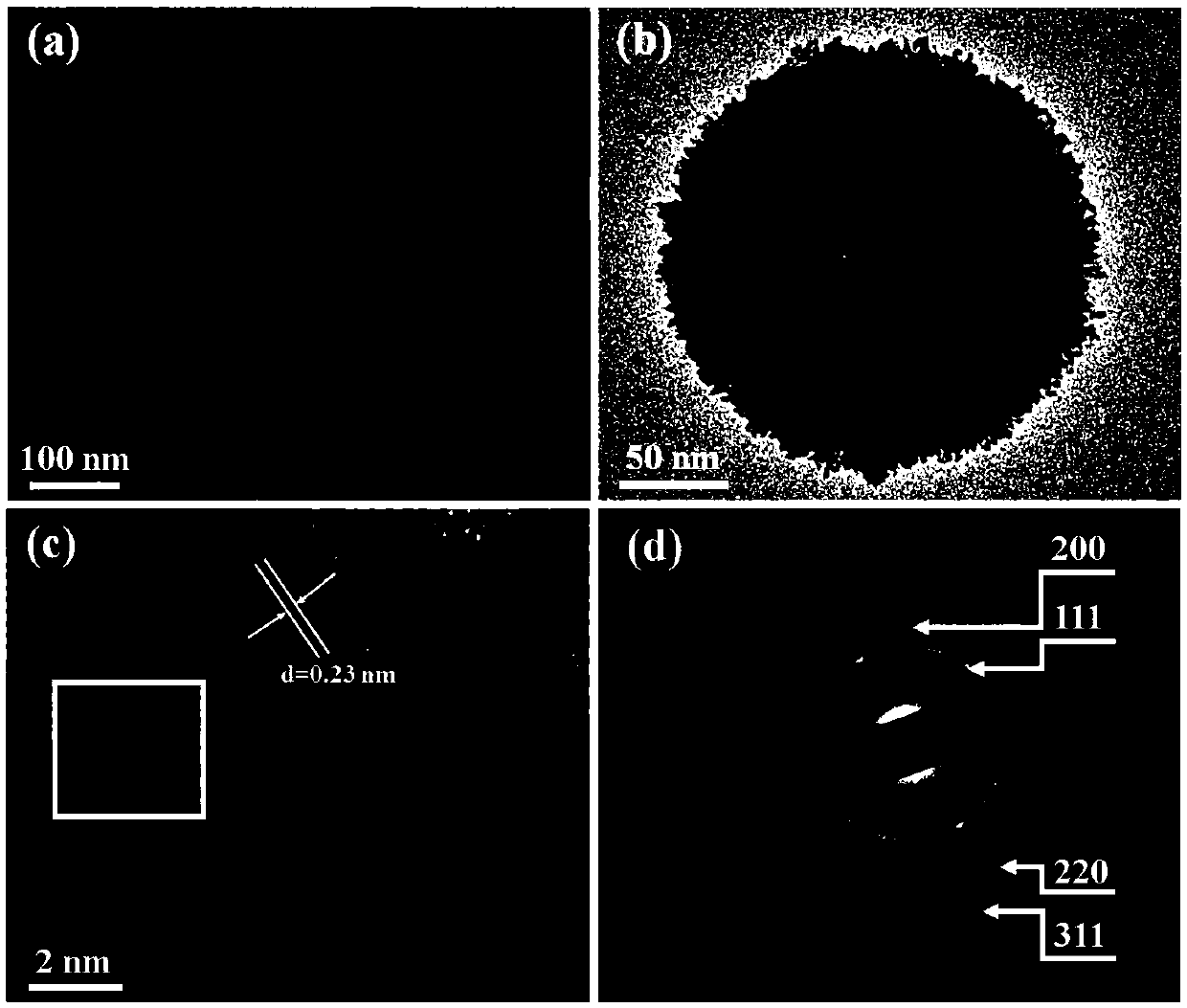

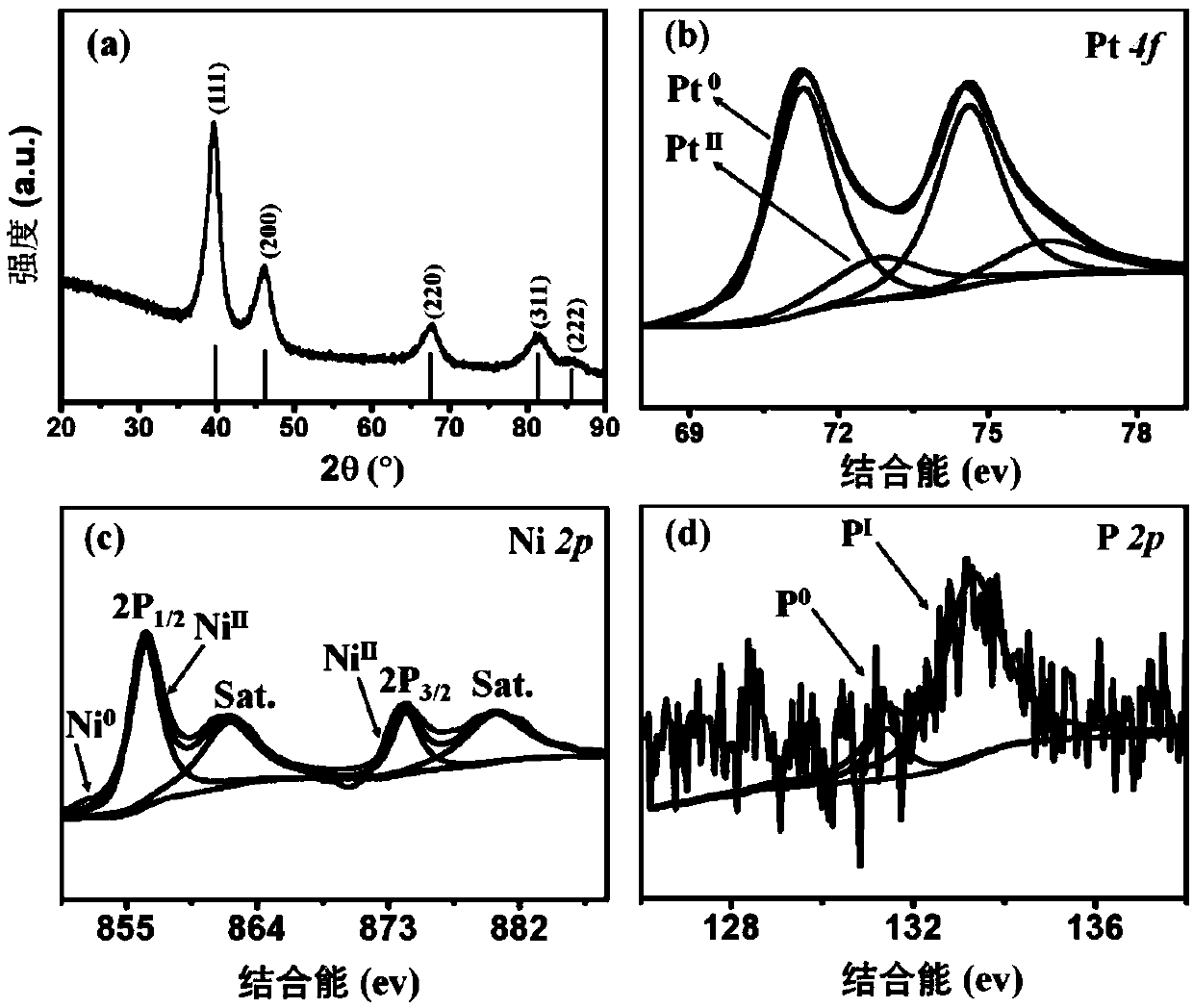

[0045] A preparation method of mesoporous platinum-nickel-phosphorus nano-cage electrocatalyst, said method comprising the steps of:

[0046] (1) Potassium chloroplatinite, 0.1M ascorbic acid, 20mM nickel chloride, 20mM sodium hypophosphite and 0.2M sodium borohydride solution were prepared respectively with a concentration of 20mM;

[0047] (2) Add 200 mL of ethanol solution dropwise to a mixed solution containing 15.2 mL of water and 6.4 mL of ammonia water, and stir at room temperature for 1 hour, then add 12 mL of tetraethyl orthosilicate dropwise to the above solution, and continue stirring for 3 hours, and then centrifuged three times each with water and ethanol. Finally, the obtained silica spheres were dried in a vacuum oven at 50° C. for 10 hours;

[0048] (3) Take 50 mg of silica spheres and ultrasonically disperse them in a mixed solution containing 10 mL of isopropanol and 200 uL of 3-aminopropyltrimethoxysiloxane, and then reflux it at 80°C for 12 hours. Finally,...

Embodiment 2

[0054] A preparation method of mesoporous platinum-nickel nano-cage electrocatalyst, said method comprising the steps of:

[0055] (1) Potassium chloroplatinite, 0.1M ascorbic acid, 20mM nickel chloride, 20mM sodium hypophosphite and 0.2M sodium borohydride solution were prepared respectively with a concentration of 20mM;

[0056] (2) Add 200 mL of ethanol solution dropwise to a mixed solution containing 15.2 mL of water and 6.4 mL of ammonia water, and stir at room temperature for 1 hour, then add 12 mL of tetraethyl orthosilicate dropwise to the above solution, and continue stirring for 3 hours, and then centrifuged three times each with water and ethanol. Finally, the obtained silica spheres were dried in a vacuum oven at 50° C. for 10 hours;

[0057] (3) Take 50 mg of silica spheres and ultrasonically disperse them in a mixed solution containing 10 mL of isopropanol and 200 uL of 3-aminopropyltrimethoxysiloxane, and then reflux it at 80°C for 12 hours. Finally, the functi...

Embodiment 3

[0064] A preparation method of mesoporous platinum-nickel nano-cage electrocatalyst, said method comprising the steps of:

[0065](1) Potassium chloroplatinite, 0.5M ascorbic acid, 50mM nickel chloride, 50mM sodium hypophosphite and 0.5M sodium borohydride solution were prepared respectively;

[0066] (2) Add 300mL ethanol solution dropwise to the mixed solution containing 20mL water and 10mL ammonia water, and stir at room temperature for 2 hours, then add 20mL tetraethyl orthosilicate dropwise to the above solution, and continue stirring for 5 hours, The product was then washed by centrifugation with water and ethanol. Finally, the obtained silica spheres were dried in a vacuum oven at 100° C. for 20 hours;

[0067] (3) 100 mg of silica spheres were ultrasonically dispersed in a mixed solution containing 20 mL of isopropanol and 300 uL of 3-aminopropyltrimethoxysiloxane, which was then refluxed at 100° C. for 20 hours. Finally, the functionalized silica spheres were centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com