Amino acid microorganism feed for pigs and production method of feed

A microbial feed, amino acid technology, applied in animal feed, animal feed, application and other directions, to improve the utilization rate, enrich the variety of amino acids, and reduce the cost of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

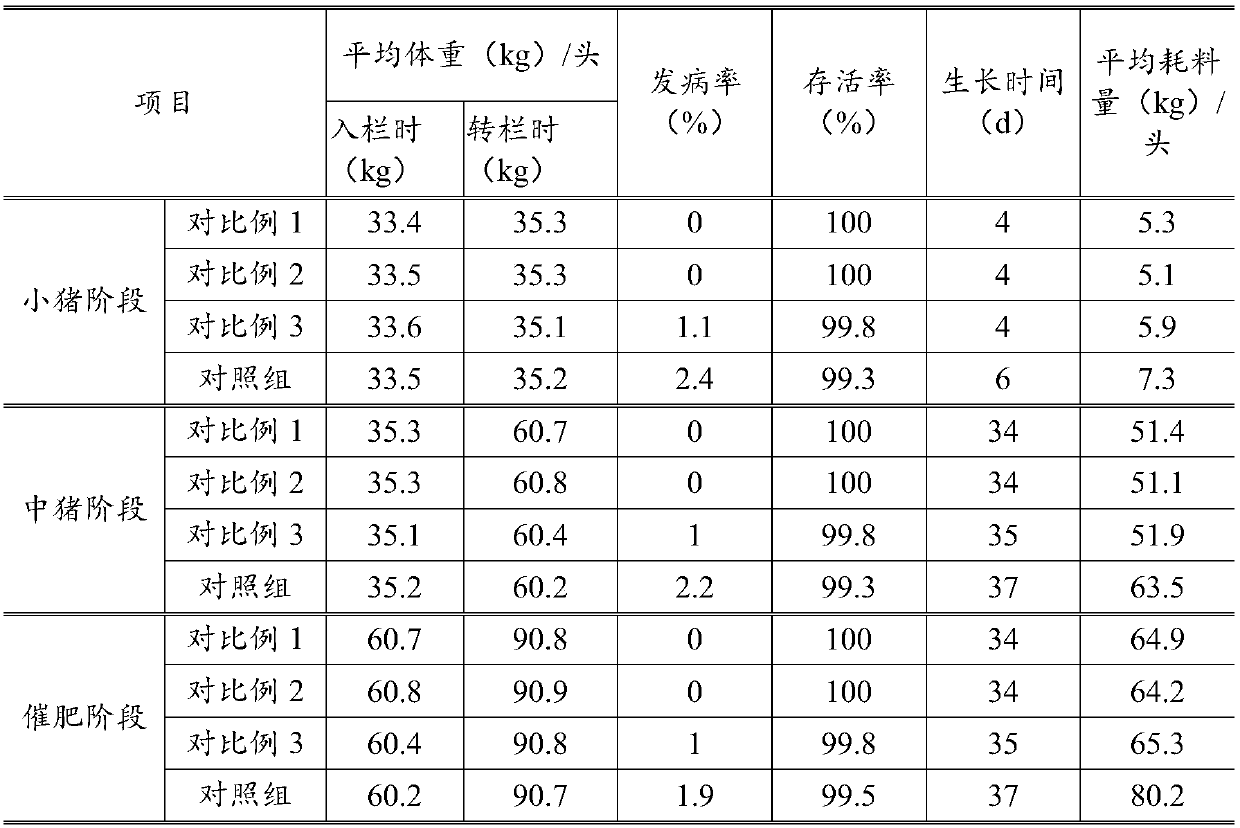

Examples

Embodiment 1

[0023] In this embodiment, a kind of amino acid microbial feed for pigs is prepared from the following raw materials in weight (kg): 81.5 kg of glutamic acid raffinate, 62.3 kg of brewer's grains, 50.2 kg of corn bran, 52.5 kg of bean dregs, 30 kg of beet dregs, peanut Shell powder 30.4kg, bone meal 20.6kg, maltodextrin 11.3kg, inorganic salt 2.1kg, compound enzyme preparation 1kg, compound vitamin 2kg and compound bacterial powder 1.15kg.

[0024] The preparation method is as follows:

[0025] (1) Preparation of inorganic salt: mixing sodium selenite, ferrous sulfate, copper sulfate and zinc sulfate with a weight ratio of 0.2:0.3:0.3:0.4, stand-by;

[0026] (2) Preparation of compound enzyme preparation: mix subtilisin and cellulase with a weight ratio of 1:1, and set aside;

[0027] (3) Preparation of multivitamins: mix vitamin B, vitamin C and vitamin E with a weight ratio of 0.2:0.2:0.1 evenly, and set aside;

[0028] (4) Preparation of composite bacterial powder: mixing...

Embodiment 2

[0034] In this embodiment, a kind of amino acid microbial feed for pigs is prepared from the following raw materials in weight (kg): 97.1 kg of glutamic acid raffinate, 78.4 kg of brewer's grains, 60 kg of corn bran, 59.8 kg of bean dregs, 38 kg of beet residue, and peanut shells Powder 38kg, bone meal 25kg, maltodextrin 15kg, inorganic salt 3kg, compound enzyme preparation 2kg, compound vitamin 3kg and compound bacterial powder 1.96kg.

[0035] The preparation method is as follows:

[0036] (1) Preparation of inorganic salt: mixing sodium selenite, ferrous sulfate, copper sulfate and zinc sulfate with a weight ratio of 0.2:0.3:0.3:0.4, stand-by;

[0037] (2) Preparation of compound enzyme preparation: mix subtilisin and cellulase with a weight ratio of 1:1, and set aside;

[0038] (3) Preparation of multivitamins: mix vitamin B, vitamin C and vitamin E with a weight ratio of 0.2:0.2:0.1 evenly, and set aside;

[0039] (4) Preparation of composite bacteria powder: mix Rhodos...

Embodiment 3

[0046]In this embodiment, a kind of amino acid microbial feed for pigs is prepared from the following raw materials in weight (kg): 81.5 kg of glutamic acid raffinate, 62.3 kg of brewer's grains, 50.2 kg of corn bran, 52.5 kg of bean dregs, 30 kg of beet dregs, peanut Shell powder 30.4kg, bone meal 20.6kg, maltodextrin 11.3kg, inorganic salt 2.1kg, compound enzyme preparation 1kg, compound vitamin 2kg and compound bacterial powder 1.15kg.

[0047] The preparation method is as follows:

[0048] (1) Preparation of inorganic salt: mixing sodium selenite, ferrous sulfate, copper sulfate and zinc sulfate with a weight ratio of 0.2:0.3:0.3:0.4, stand-by;

[0049] (2) Preparation of compound enzyme preparation: mix subtilisin and cellulase with a weight ratio of 1:1, and set aside;

[0050] (3) Preparation of multivitamins: mix vitamin B, vitamin C and vitamin E with a weight ratio of 0.2:0.2:0.1 evenly, and set aside;

[0051] (4) Preparation of composite bacterial powder: mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com