Electrochemical self-doped WO3 particle-supported TiO2 nanotube, and preparation method and application thereof

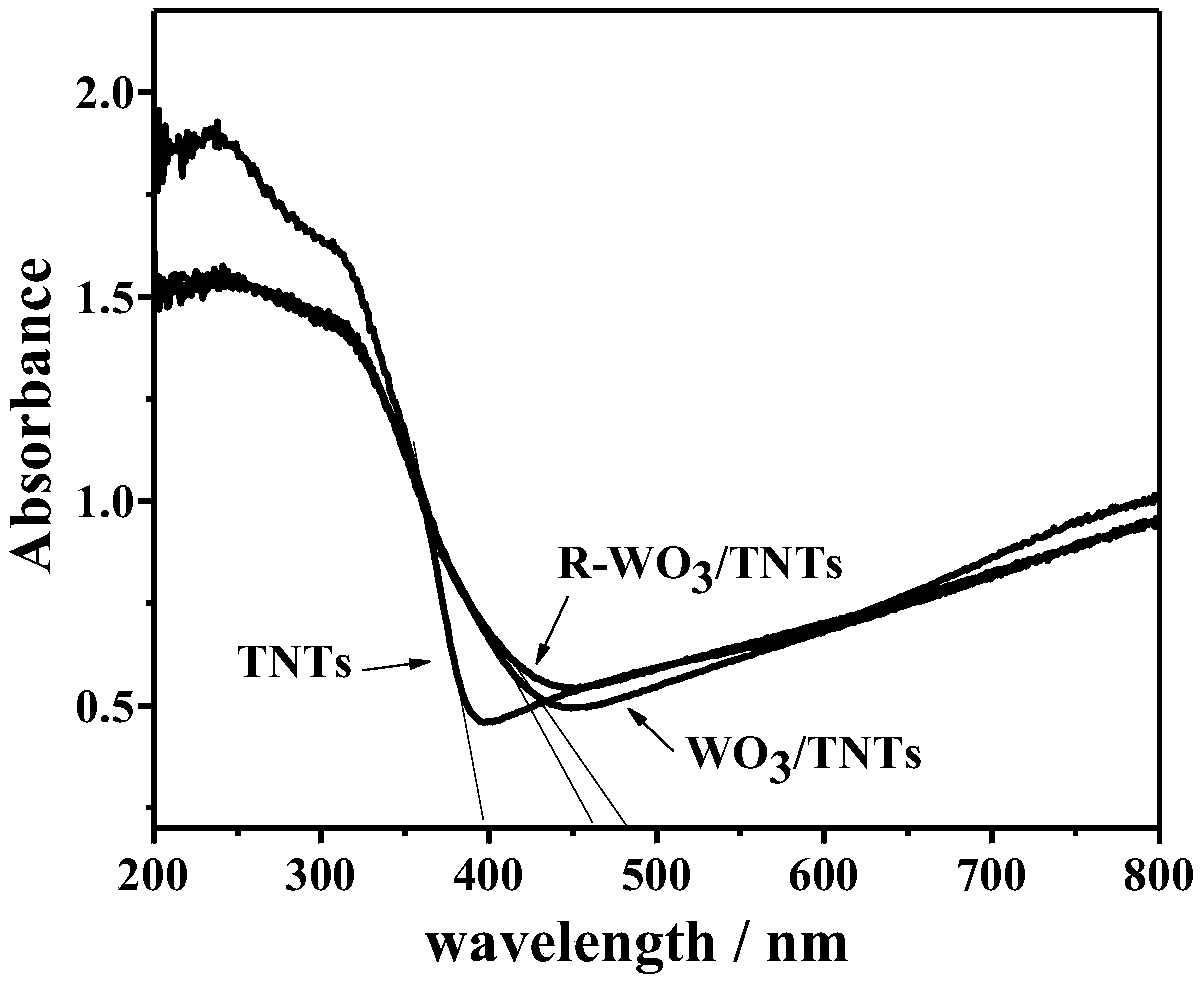

A nanotube, electrochemical technology, applied in the field of photocatalytic materials, can solve the problems of poor photocatalytic photocatalytic performance, limited capacity, narrow visible light response range, etc., to achieve the effect of improving photocatalytic performance and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Modified self-doping WO 3 Particle loaded TiO 2 A method for preparing nanotubes, comprising the steps of:

[0043] (1) Under the two-electrode system, the titanium sheet was placed as the working electrode in the - In the electrolytic solution, etch for 2-20 hours under the condition of constant voltage of 20V-80V. Will get TiO 2 The nanotube precursor is fired at a certain temperature of 400-600°C for 60-240min to obtain TiO 2 nanotube.

[0044] TiO can also be prepared by sol-gel method, hydrothermal method, magnetron sputtering method or atomic layer deposition method in the prior art 2 precursor, and then calcined to obtain TiO 2 Nano.

[0045] (2) the precursor TiO obtained in step (1) 2 The nanotube precursor is used as the working electrode. Under the three-electrode system, the electrochemical deposition method is used, and the mixed solution of EDTA, ammonium acetate and sodium tungstate is used as the electrolyte. Under the condition of constant curre...

Embodiment 1

[0049] A modified self-doping TiO 2 A method for preparing a nanotube-based visible light photocatalyst, comprising the following steps: the photocatalyst is visible light responsive TiO 2 Nanotube-based photocatalysts.

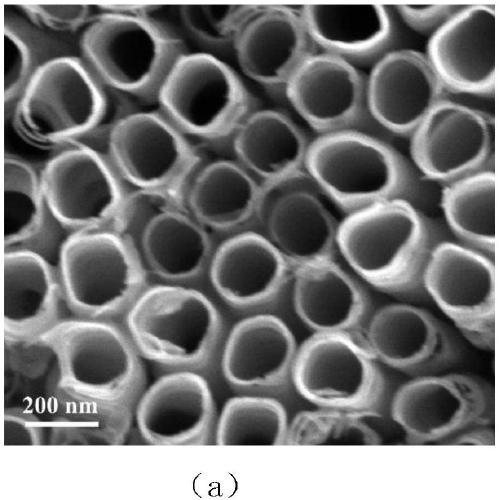

[0050] (1) Preparation of TiO 2 nanotube

[0051] The Ti sheet was cut to a size of 3cm×3.5cm, immersed in an ethylene glycol solution containing 3.119g / L ammonium fluoride and 13.75% (volume ratio) deionized water under a two-electrode system, and a platinum electrode was used as a counter electrode at 60V Voltage etching for 8 hours. Will get TiO 2 The nanotube precursor was placed in a muffle furnace and calcined at 450 °C for 120 min to obtain anatase TiO 2 nanotube.

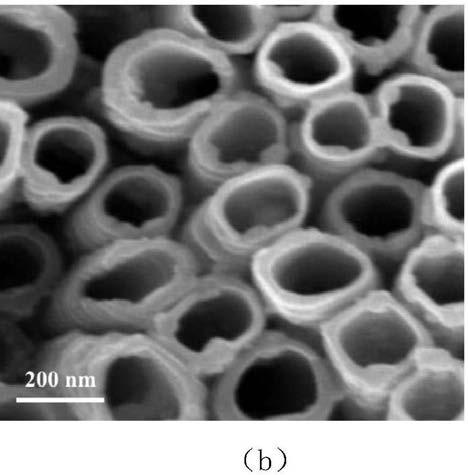

[0052] (2) Preparation of WO 3 / TiO 2 nanotube

[0053] With the TiO obtained in step (1) 2 The nanotube was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. 3 E...

Embodiment 2

[0075] A modified self-doping TiO 2 A method for preparing a nanotube-based visible light photocatalyst, comprising the following steps: the photocatalyst is visible light responsive TiO 2 Nanotube-based photocatalysts.

[0076] (1) Preparation of TiO 2 nanotube

[0077] The Ti sheet was cut to a size of 3cm×3.5cm, immersed in an ethylene glycol solution containing 0.1g / L ammonium fluoride and 20% (volume ratio) deionized water under a two-electrode system, and a platinum electrode was used as a counter electrode at 20V Voltage etching for 20 hours. Will get TiO 2The nanotube precursor was placed in a muffle furnace and calcined at 400 °C for 240 min to obtain anatase TiO 2 nanotube.

[0078] (2) Preparation of WO 3 / TiO 2 nanotube

[0079] With the TiO obtained in step (1) 2 The nanotube was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. 3 Electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com