Method for preparing biomass oil by improving bagasse by using molecular sieve catalyst

A technology of biomass oil and molecular sieve, which is applied in the preparation of liquid hydrocarbon mixtures, pressure vessels used in chemical processes, chemical/physical/physicochemical fixed reactors, etc., can solve the problems of no research and achieve high biomass conversion rate , low acid value and low technology conversion cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

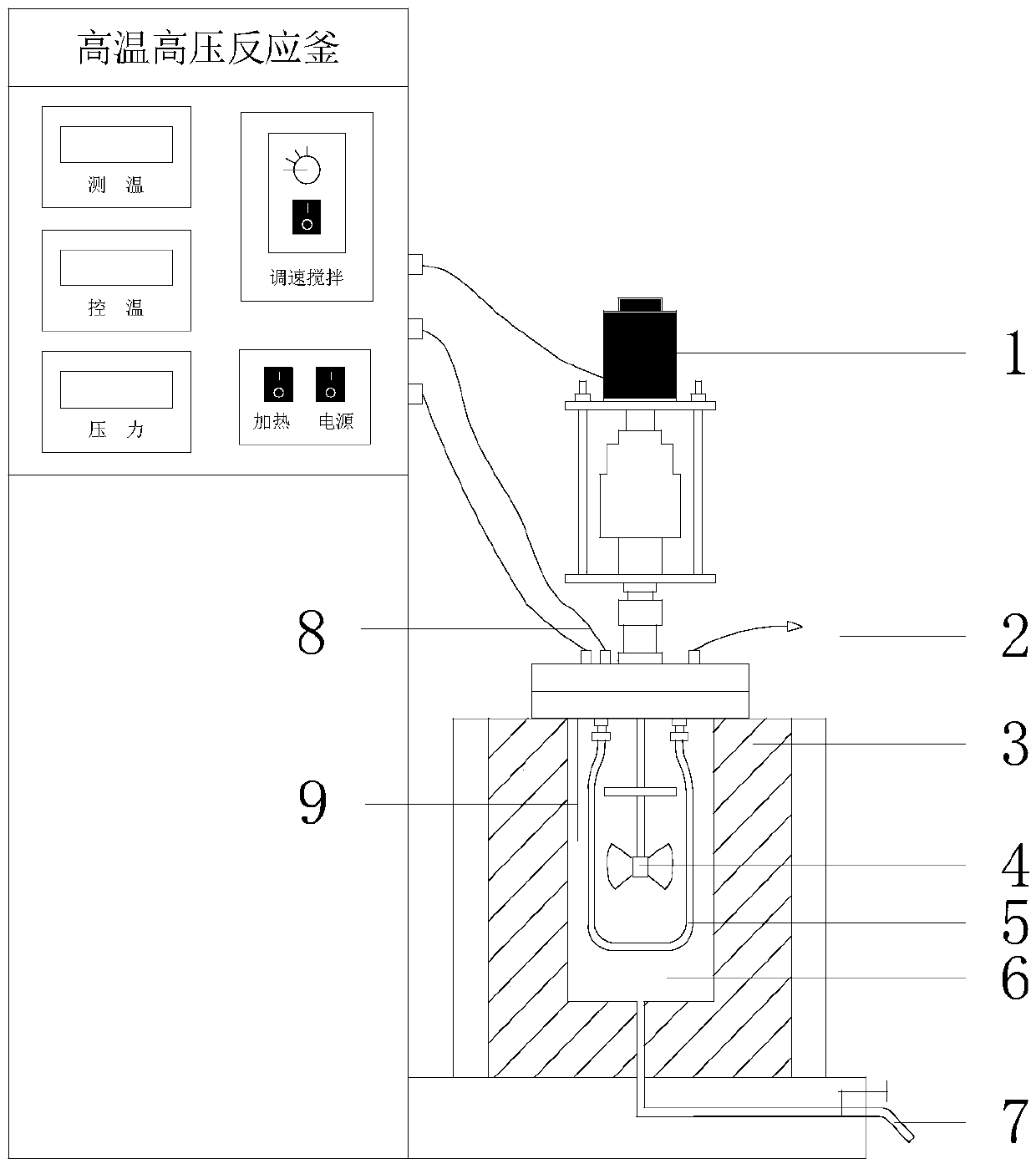

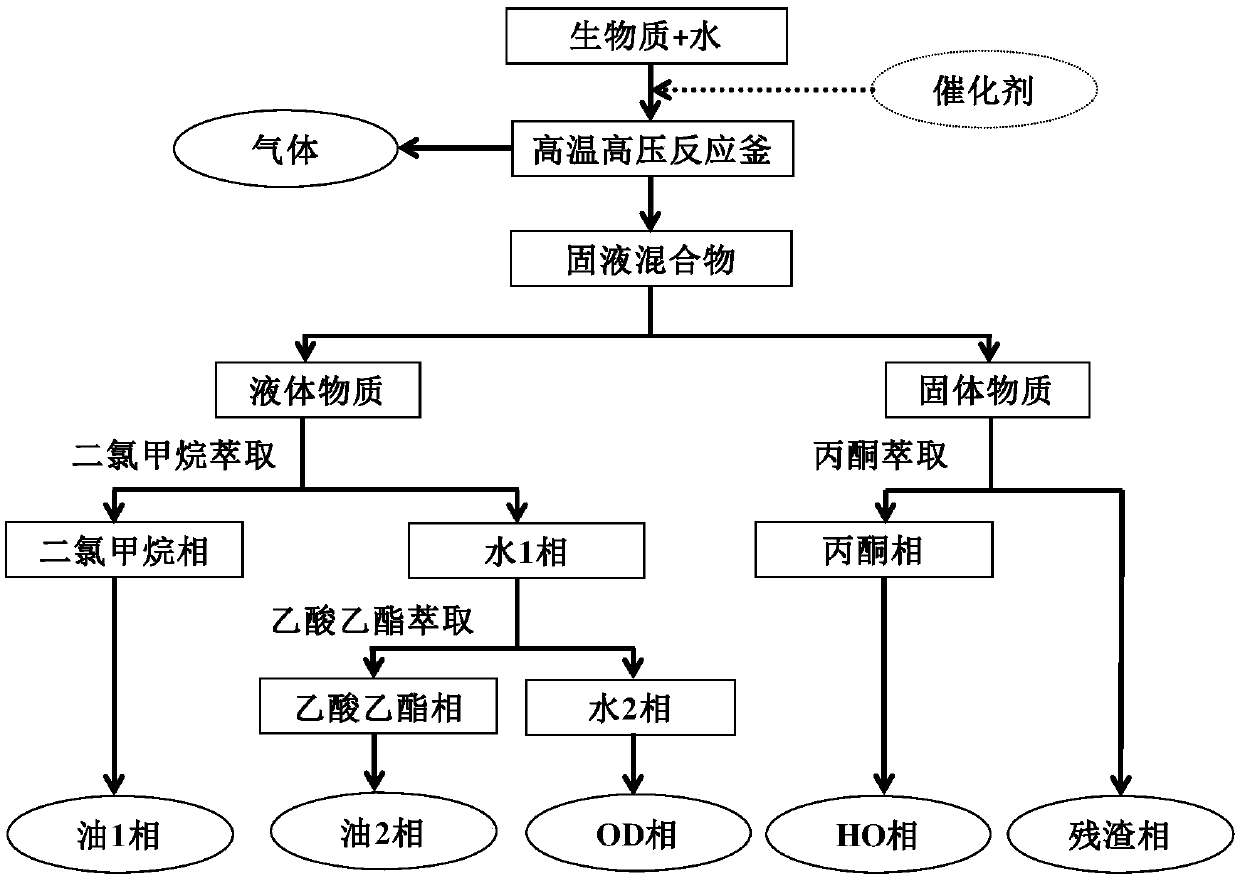

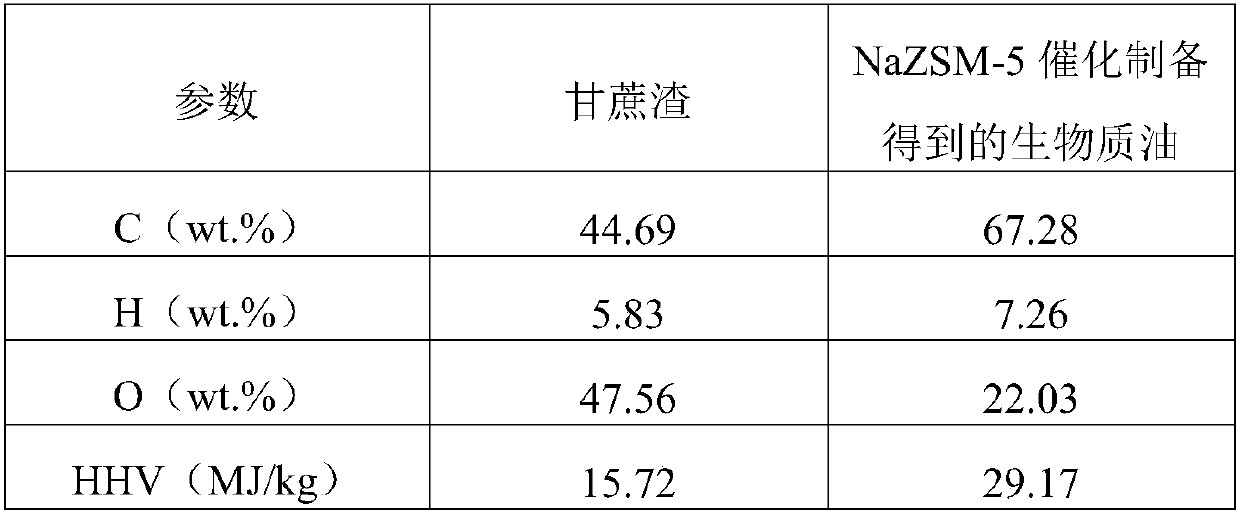

[0039] This embodiment provides a method for improving bagasse to prepare biomass oil by using a molecular sieve catalyst, such as figure 2 As shown in the process flow diagram of the method, the method may further comprise the steps:

[0040]Step 1: Add bagasse and deionized water into the high-temperature and high-pressure reaction kettle according to the material ratio of 1:20, and the addition amount of NaZSM-5 molecular sieve is 3.00g, and then heat the reaction kettle. When the reaction kettle reaches the preset reaction temperature of 285 At ℃, keep the constant temperature for 30 minutes, and finally pass in cooling water to cool down, and react to obtain a solid-liquid mixed product;

[0041] Step 2: After the solid-liquid mixed product obtained in the liquefaction process is vacuum-filtered and separated, the solid phase in the reaction product is washed with 300 mL of acetone several times and filtered with suction, and the acetone-soluble organic phase is rotary ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap