Screening method for lactobacillus acidophilus amino acid requirements

A Lactobacillus acidophilus, amino acid technology, applied in biochemical equipment and methods, microbial determination/inspection, etc., can solve problems such as being unsuitable for large-scale screening of enterprises, high cost, and complicated preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

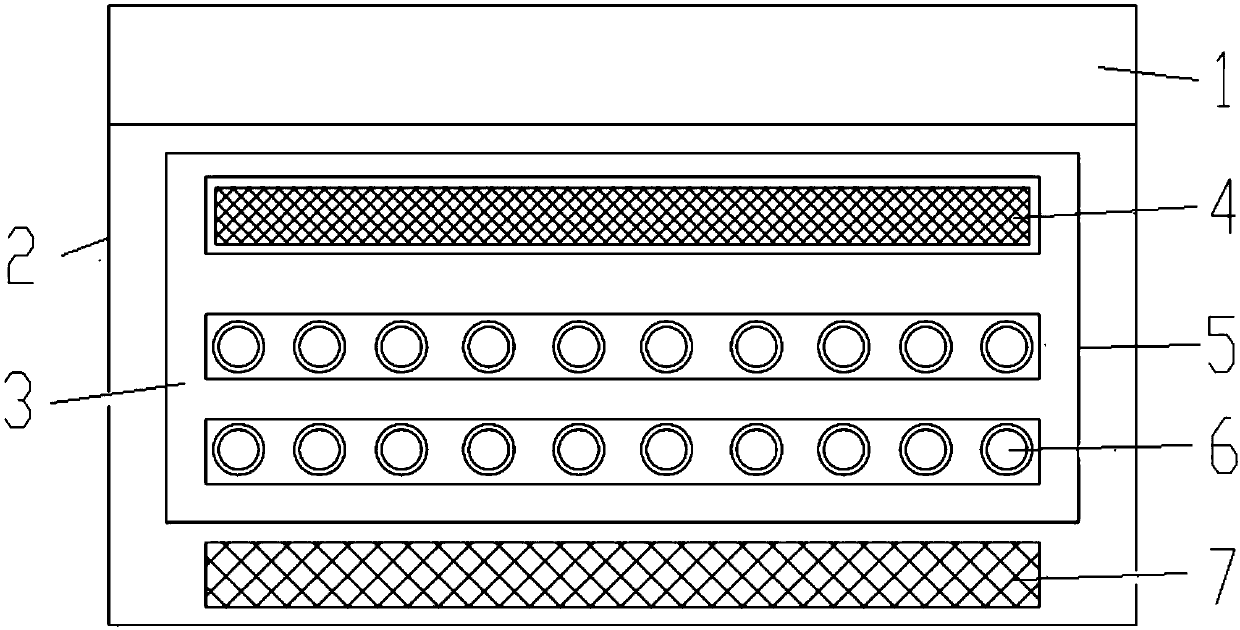

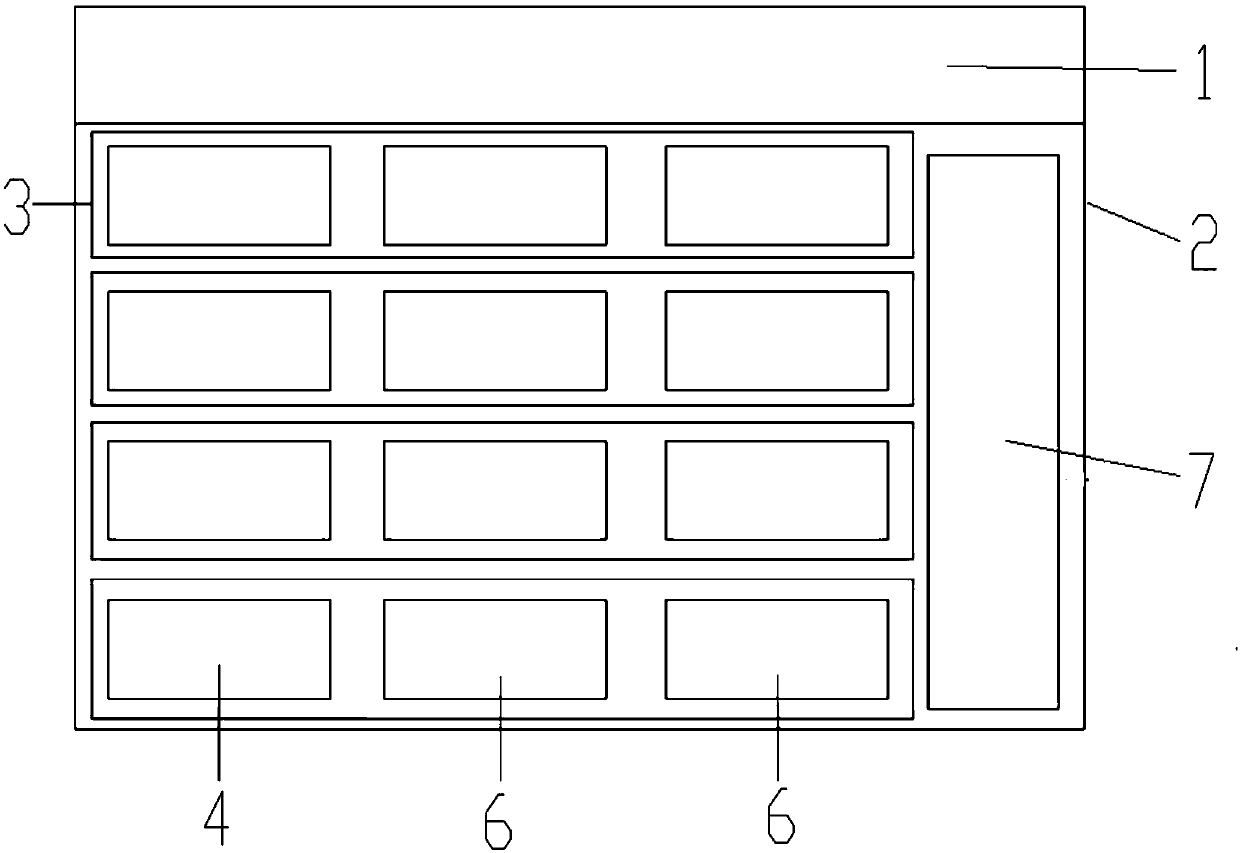

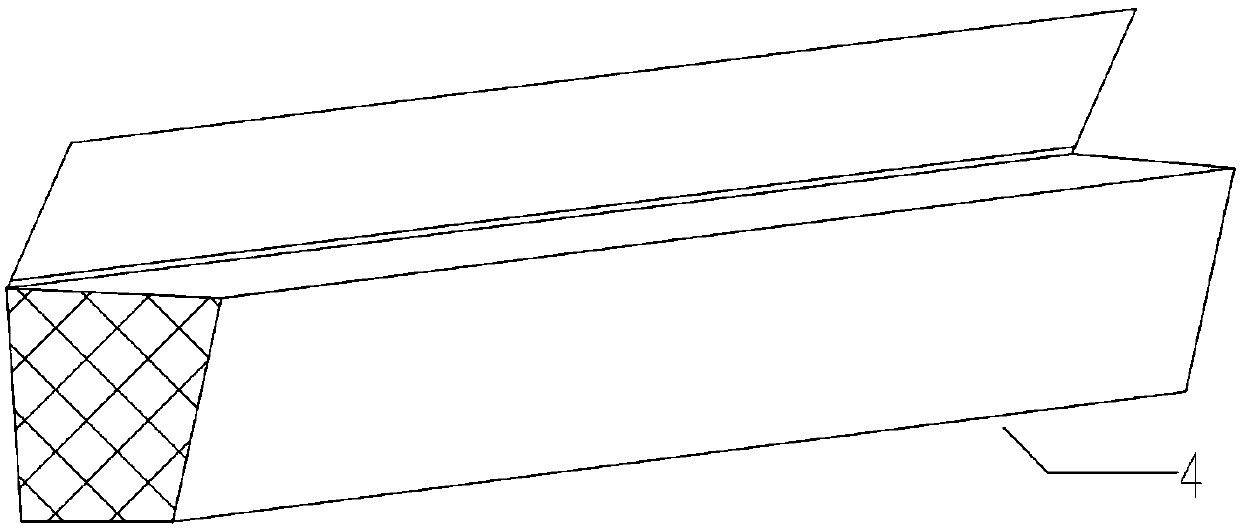

Image

Examples

Embodiment 1

[0056] Inoculate the Lactobacillus acidophilus strain 007 frozen at -80°C in the basal medium (basic medium: glucose: 20g / L, peptone: 10g / L, beef extract powder: 10g / L, yeast extract: 5g / L, Dipotassium hydrogen phosphate: 2g / L, diamine hydrogen citrate: 2g / L, sodium acetate: 5g / L, magnesium sulfate heptahydrate: 0.25g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80 : 1g / L) at 37°C for 12h. The activated seed culture medium was taken with 1% inoculum volume, centrifuged to remove the medium, and then resuspended in an equal amount of sterile water for inoculation.

[0057] Prepare control medium: glucose: 30g / L, yeast extract: 0.1g / L, tryptophan: 0.1g / L, asparagine: 0.1g / L, isoleucine: 0.1g / L, lysine : 0.1g / L, glycine: 0.1g / L, leucine: 0.1g / L, serine: 0.1g / L, histidine: 0.1g / L, tyrosine: 0.1g / L, cysteine : 0.1g / L, Valine: 0.1g / L, Phenylalanine: 0.1g / L, Aspartic Acid: 0.1g / L, Glutamic Acid: 0.1g / L, Threonine: 0.1g / L, alanine: 0.1g / L, methionine: 0.1g / L, proline: 0.1g / L, ...

Embodiment 2

[0065] Inoculate the Lactobacillus acidophilus strain 008 frozen at -80°C in the basal medium (basic medium: glucose: 20g / L, peptone: 10g / L, beef extract powder: 10g / L, yeast extract: 5g / L, Dipotassium hydrogen phosphate: 2g / L, diamine hydrogen citrate: 2g / L, sodium acetate: 5g / L, magnesium sulfate heptahydrate: 0.25g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80 : 1g / L) at 37°C for 12h. The activated seed culture medium was taken with 1% inoculum volume, centrifuged to remove the medium, and then resuspended in an equal amount of sterile water for inoculation.

[0066] Preparation of control medium: glucose: 20g / L, yeast extract: 0.25g / L, tryptophan: 0.1g / L, asparagine: 0.1g / L, isoleucine: 0.1g / L, lysine : 0.1g / L, Glycine: 0.1g / L, Leucine: 0.1g / L, Serine: 0.1g / L, Histidine: 0.1g / L, Tyrosine: 0.1g / L, Cysteine Acid: 0.1g / L, Valine: 0.1g / L, Phenylalanine: 0.1g / L, Aspartic Acid: 0.1g / L, Glutamic Acid: 0.1g / L, Threonine: 0.1 g / L, alanine: 0.1g / L, methionine: 0.1g / L, proli...

Embodiment 3

[0073] Inoculate the Lactobacillus acidophilus strain 009 frozen at -80°C into the basal medium (basic medium: glucose: 20g / L, peptone: 10g / L, beef extract powder: 10g / L, yeast extract: 5g / L, Dipotassium hydrogen phosphate: 2g / L, diamine hydrogen citrate: 2g / L, sodium acetate: 5g / L, magnesium sulfate heptahydrate: 0.25g / L, manganese sulfate monohydrate: 0.05g / L, Tween-80 : 1g / L) at 37°C for 12h. The activated seed culture medium was taken with 1% inoculum volume, centrifuged to remove the medium, and then resuspended in an equal amount of sterile water for inoculation.

[0074] Preparation of control medium: glucose: 20g / L, yeast extract: 0.1g / L, tryptophan: 0.1g / L, asparagine: 0.1g / L, isoleucine: 0.1g / L, lysine : 0.1g / L, Glycine: 0.1g / L, Leucine: 0.1g / L, Serine: 0.1g / L, Histidine: 0.1g / L, Tyrosine: 0.1g / L, Cysteine Acid: 0.1g / L, Valine: 0.1g / L, Phenylalanine: 0.1g / L, Aspartic Acid: 0.1g / L, Glutamic Acid: 0.1g / L, Threonine: 0.1 g / L, alanine: 0.1g / L, methionine: 0.1g / L, prol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com