Negative electrode comprising solid electrolyte and low porosity and lithium battery applying the negative electrode

A technology of solid electrolyte and porosity, applied in the direction of non-aqueous electrolyte battery electrodes, negative electrodes, battery electrodes, etc., can solve the problems of poor electrochemical and chemical stability, limit the use range of thin film batteries, and interface stability problems, etc. Achieve the effects of reducing electrode porosity, improving electrode ion transmission capacity, and reducing electrode impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a negative electrode comprising a solid electrolyte and low porosity, the method is as follows:

[0035] (1) Select D50 (15.9μm) silicon-carbon composite material, D50 (2.5μm) silicon-carbon composite material and D50 (500nm) solid electrolyte LLZTO powder, according to large particles: medium particles: small particles = 7:2: 1 (actual volume ratio) to perform 3-level gradation, check the true density of each component, calculate the mass ratio, and weigh a powder material with a total weight of 190g.

[0036] (2) Mix 56g of N-methylpyrrolidone, 100g of 6% PVDF glue, 1.5g of SP conductive agent and weighed 190g of powder material, use a homogenizer to homogenate, and disperse at a speed of 1000 rpm 5min, 5000rpm rotation speed dispersion for 5min, 7000rpm rotation speed dispersion for 5min, repeat 4 times, after the slurry is cooled, the viscosity of the test slurry is 3600Pa·s, and the test slurry fineness is 35μm, then, on the coating machine ...

Embodiment 2

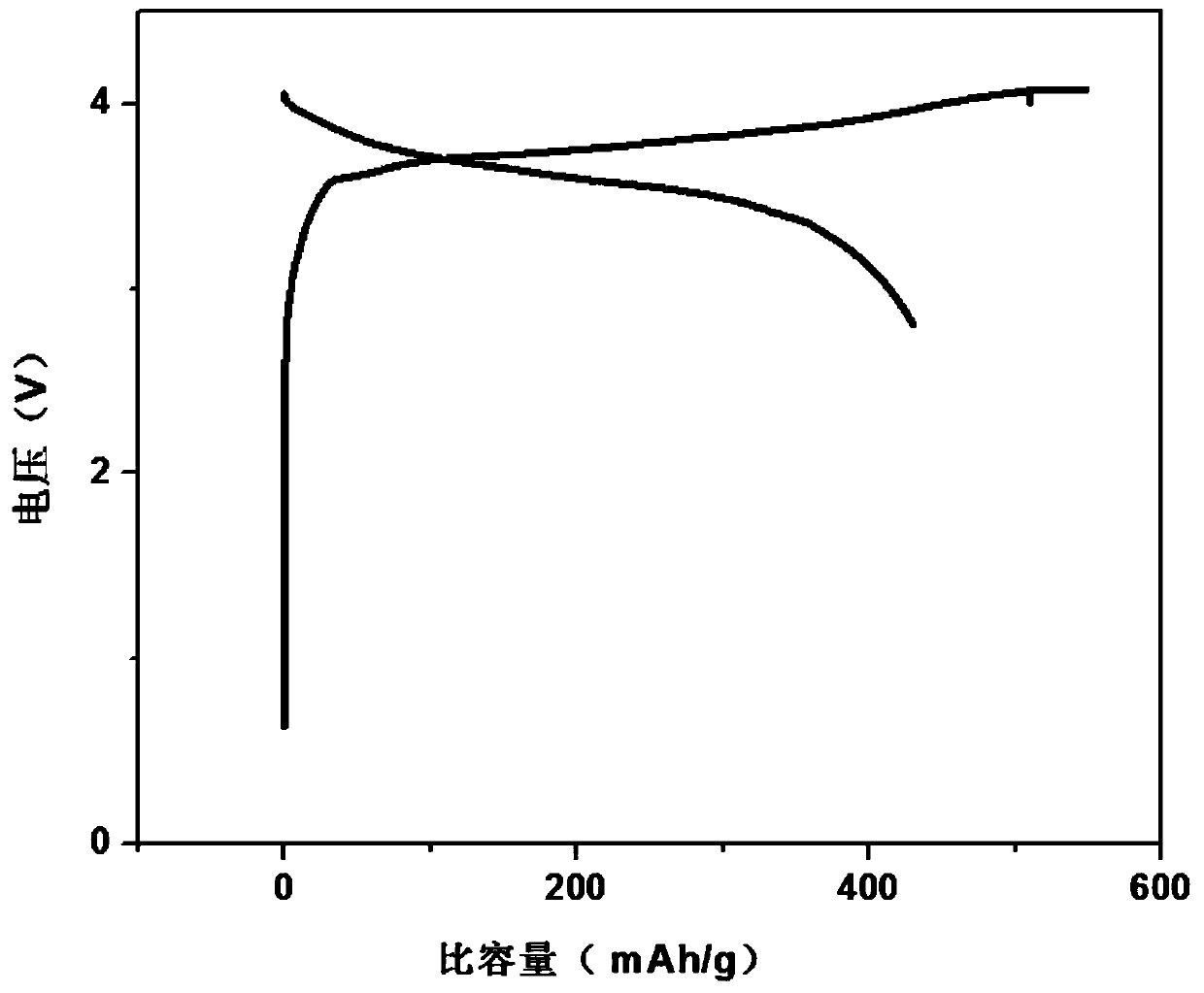

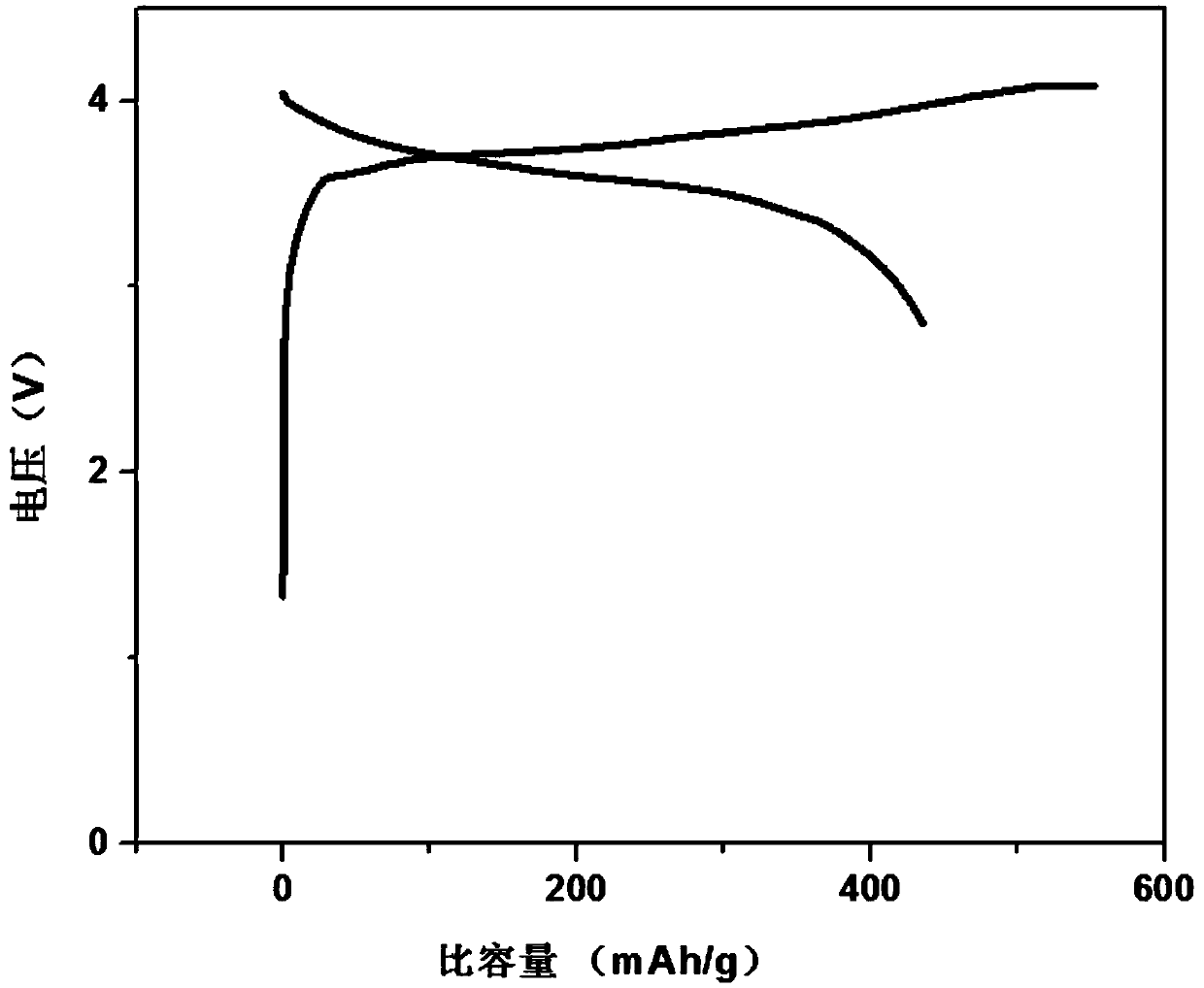

[0039] A kind of lithium-ion battery, described lithium-ion battery is formed by placing described negative pole containing solid state electrolyte, low porosity and electric compatibility positive pole, separator, electrolyte in container, and its method is as follows:

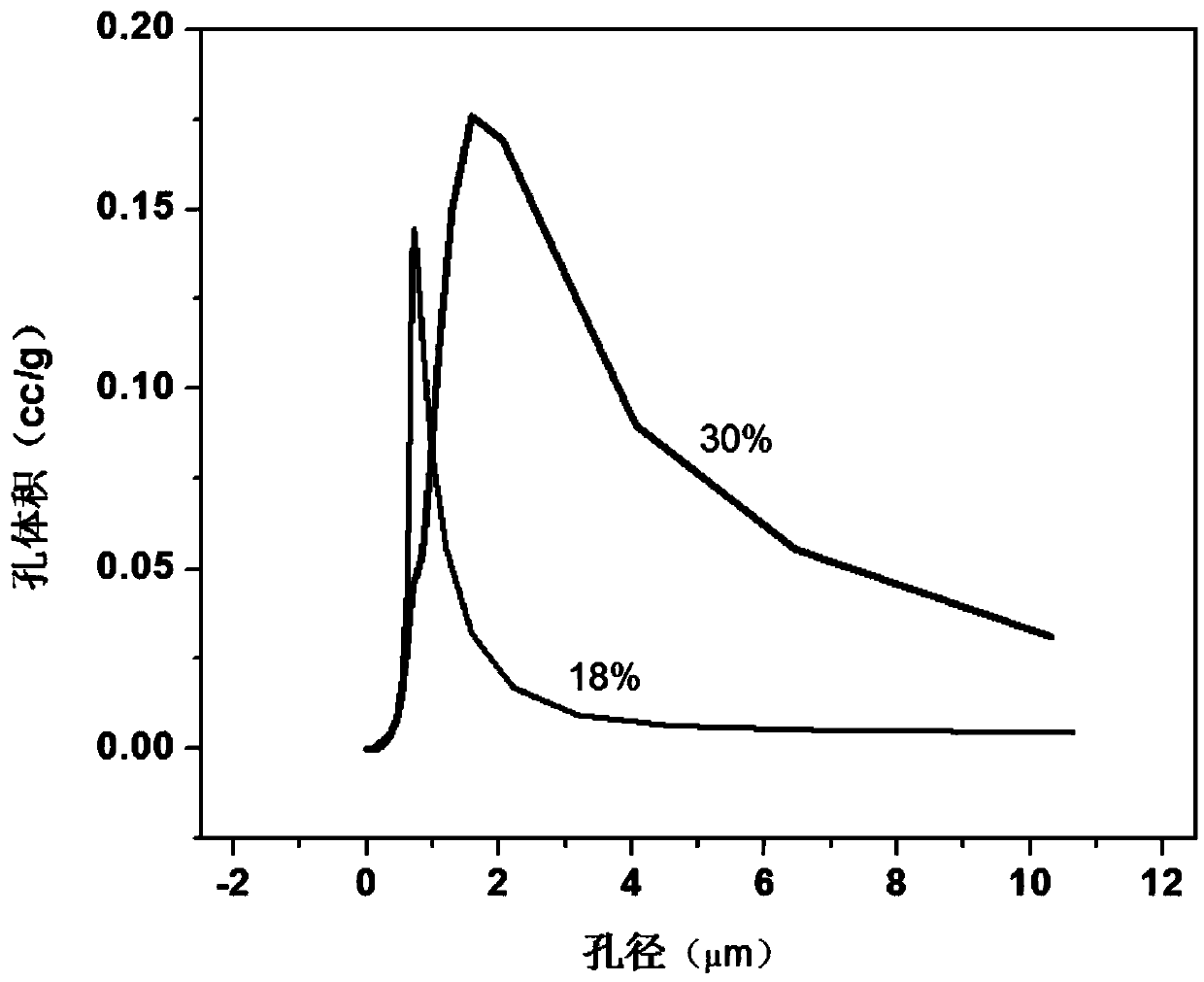

[0040] (1) According to steps (2) and (3) in Example 1, prepare NCM523 positive pole piece, according to the P / N ratio is 1.15, the surface density of the prepared positive pole piece is 26.1mg / cm 2 After rolling, a pole piece with a porosity of 30% and a positive electrode coated on one side was obtained, and the pole piece was cut into a required size, dried and weighed.

[0041] (2) Use the cut positive pole piece and negative pole piece, and the diaphragm with a thickness of 32 μm to laminate, then weld the positive pole piece and the negative pole piece to the tabs, and finally, package the battery in aluminum plastic film, aluminum A hole is left on the top of the plastic film to inject liquid. The amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com