Livestock and poultry manure composting additive and application thereof

A technology of livestock and poultry manure and additives, applied in the field of solid waste recycling, can solve problems such as rising, achieve the effect of improving compost quality, meeting the requirements of industrial scale production, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 compost additive

[0041] (1) Zeolite was purchased from Boluo Gongzhuang Zeolite Powder Factory in Guangdong Province. Zeolite is a natural zeolite with a diameter between 0.85mm-2.00mm; ferrous sulfate was purchased from Zhenjiang Ruixin Chemical Co., Ltd.; superphosphate was purchased from Guangdong Guang Yeyun Sulfur Mining Co., Ltd., P 2 o 5 Mass fraction ≥ 12%.

[0042] (2) Preparation of Bacillus subtilis WJC11 (CGMCC No.4440) and Bacillus cereus WJC2 (CGMCC No.4441) liquid inoculum and solid inoculum: the preserved strains were inoculated on J medium (Shu Dan, Li Hong, Yan Jianhua, Chen Jinrui, Li Hui, Liu Chengjun. Fermentation Conditions and Enzymatic Properties of Alkaline Protease from Bacillus Thermopylae [J]. Journal of Sichuan University (Natural Science Edition), 2004, 41(4):856-860.) Via Shaker After liquid expansion culture, it is inoculated into J medium and obtained according to conventional liquid or solid fermenta...

Embodiment 2

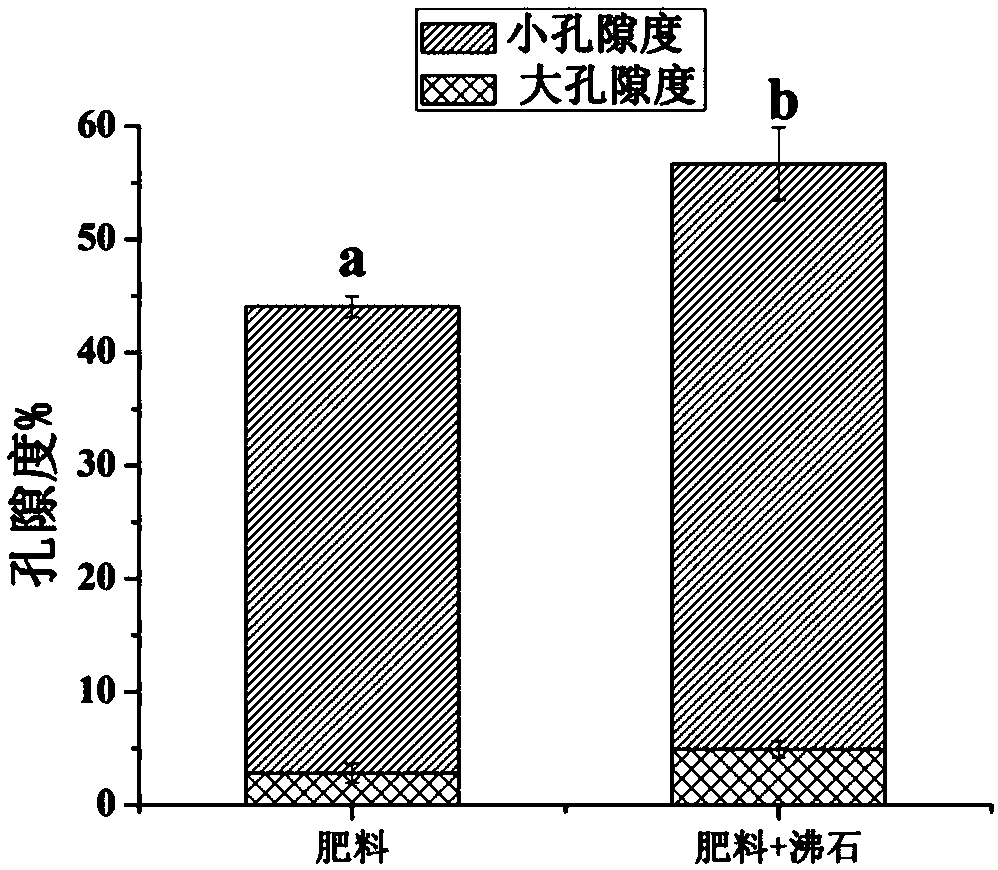

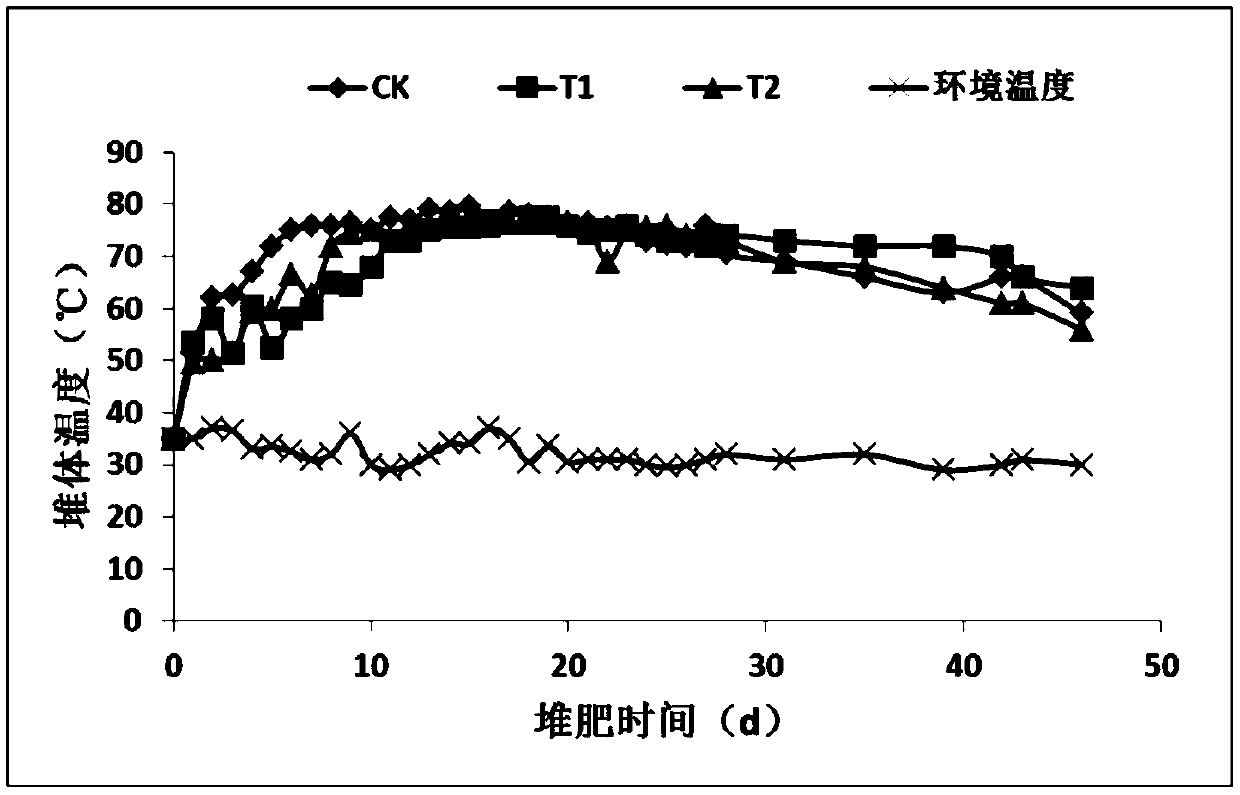

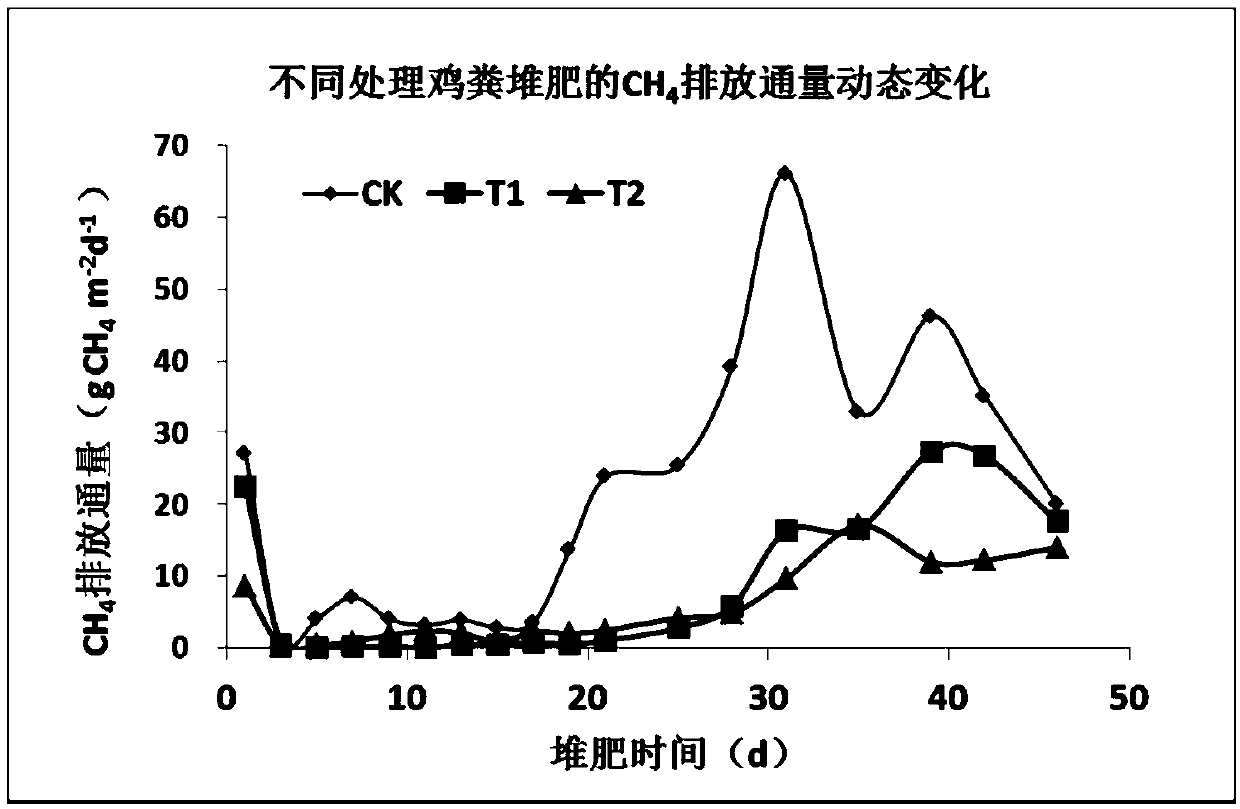

[0047] Application effect of embodiment 2 compost additives in chicken manure composting

[0048] 3 treatments are set, and the material composition of contrast and additive treatment is shown in Table 1, wherein compost additive is prepared according to the method for embodiment 1, Bacillus subtilis WJC11 (CGMCC No.4440) and Bacillus cereus WJC2 (CGMCC No.4441) The bacterial agent is a solid bacterial agent.

[0049] Additive 1: According to the mixture A of ferrous sulfate and zeolite, superphosphate, Bacillus subtilis WJC11 (CGMCC No.4440) and Bacillus cereus WJC2 (CGMCC No.4441) suitable for high-temperature composting according to mass ratio 1: 80:1:1 composition of the mixture.

[0050] Additive 2: According to the mixture A of ferrous sulfate and zeolite, superphosphate, Bacillus subtilis WJC11 (CGMCC No.4440) and Bacillus cereus WJC2 (CGMCC No.4441) suitable for high-temperature composting according to the mass ratio of 50: 30:1:1 mixture.

[0051] Composting raw ma...

Embodiment 3

[0065] Application effect of embodiment 3 composting additives in cow dung composting

[0066] 3 processes are set, and the material composition of contrast and additive treatment is shown in Table 3, wherein compost additive is directly added in compost raw material according to the method and mass ratio of embodiment 1, Bacillus subtilis WJC11 (CGMCC No.4440) and Bacillus cereus WJC2 (CGMCC No.4441) bacterial agent is a liquid bacterial agent. Composting raw materials are fresh cow dung and rice bran with a fresh mass ratio of 4:1.

[0067] After mixing, adjust the moisture content of the compost heap to 60%. The heap is in the shape of a triangular prism with a height of about 1.1-1.2m and a bottom width of about 2.0-2.2m.

[0068] Table 3 Composition of different treated materials (unit: kg)

[0069]

[0070] Each stack is turned by a stacker, and the stack is turned every 2 days (about 48 hours) during the stacking period. Immediately after the stack is turned, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com