Lactobacillus reuteri high-density fermentation medium and fermentation method and application

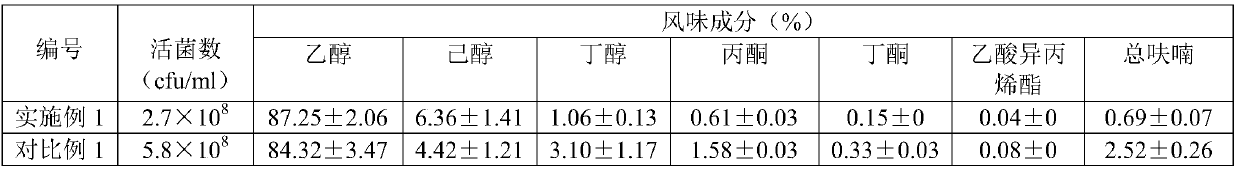

A Lactobacillus reuteri, high-density fermentation technology, applied in the field of microbial fermentation, can solve problems such as bad flavor, achieve the effects of improving the flavor of the culture medium, simplifying the process flow, and improving the flavor of the fermentation broth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Inoculate the Lactobacillus reuteri strain in the seed medium, culture it anaerobically at 37° C. for 16 hours, and cultivate the seed solution; the seed medium is a traditional MRS medium, and each liter of the seed medium includes: glucose 20g, tryptone 5g, beef extract 10g, yeast powder 50g, soytone 5g, manganese sulfate 0.58g, magnesium sulfate 0.28g, Tween 80 0.1g, cysteine hydrochloride 0.5g, dipotassium hydrogen phosphate 2g, Diamine hydrogen citrate 2g and sodium acetate 10g;

[0032] (2) Inoculate the seed solution in a 6L Lactobacillus reuteri high-density fermentation medium (a fermenter with a capacity of 10L) at an inoculum size of 5% (v / v), and feed CO at 37°C. 2, the stirring speed is controlled at 120rpm, and the fermentation culture is carried out under anaerobic stirring conditions for 20 hours; each liter of Lactobacillus reuteri high-density fermentation medium includes the following raw materials: 30g of maltose, 80g of soybean peptone, 65g of...

Embodiment 2

[0034] (1) Inoculate the Lactobacillus reuteri strain in the seed medium, culture it anaerobically at 37° C. for 15 hours, and cultivate the seed solution; the seed medium is a traditional MRS medium, and each liter of the seed medium includes: glucose 20g, tryptone 5g, beef extract 10g, yeast powder 50g, soytone 5g, manganese sulfate 0.58g, magnesium sulfate 0.28g, Tween 80 0.1g, cysteine hydrochloride 0.5g, dipotassium hydrogen phosphate 2g, Diamine hydrogen citrate 2g and sodium acetate 10g;

[0035] (2) Inoculate the seed solution with an inoculum amount of 1% (v / v) in 80ml Lactobacillus reuteri high-density fermentation medium (blue cap bottle with a capacity of 100ml), and pass CO under the condition of 35°C. 2 , the stirring speed is controlled at 130rpm, and the fermentation culture is carried out under anaerobic stirring conditions for 24 hours; each liter of Lactobacillus reuteri high-density fermentation medium includes the following raw materials: maltose 10g, so...

Embodiment 3

[0037] (1) Inoculate the Lactobacillus reuteri strain in the seed medium, culture it anaerobically at 37° C. for 12 hours, and cultivate the seed solution; the seed medium is a traditional MRS medium, and each liter of the seed medium includes: glucose 20g, tryptone 5g, beef extract 10g, yeast powder 50g, soytone 5g, manganese sulfate 0.58g, magnesium sulfate 0.28g, Tween 80 0.1g, cysteine hydrochloride 0.5g, dipotassium hydrogen phosphate 2g, Diamine hydrogen citrate 2g and sodium acetate 10g;

[0038] (2) Inoculate the seed liquid in the high-density fermentation medium of Lactobacillus reuteri with an inoculum size of 10% (v / v), and at 38°C, pass CO 2 , the stirring speed is controlled at 100rpm, and the fermentation culture is carried out under anaerobic stirring conditions for 16 hours; each liter of Lactobacillus reuteri high-density fermentation medium includes the following raw materials: 50g of maltose, 60g of soybean peptone, 30g of malt extract powder, 15g of yeas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com