Application of integrated structure in solid-state lithium ion battery

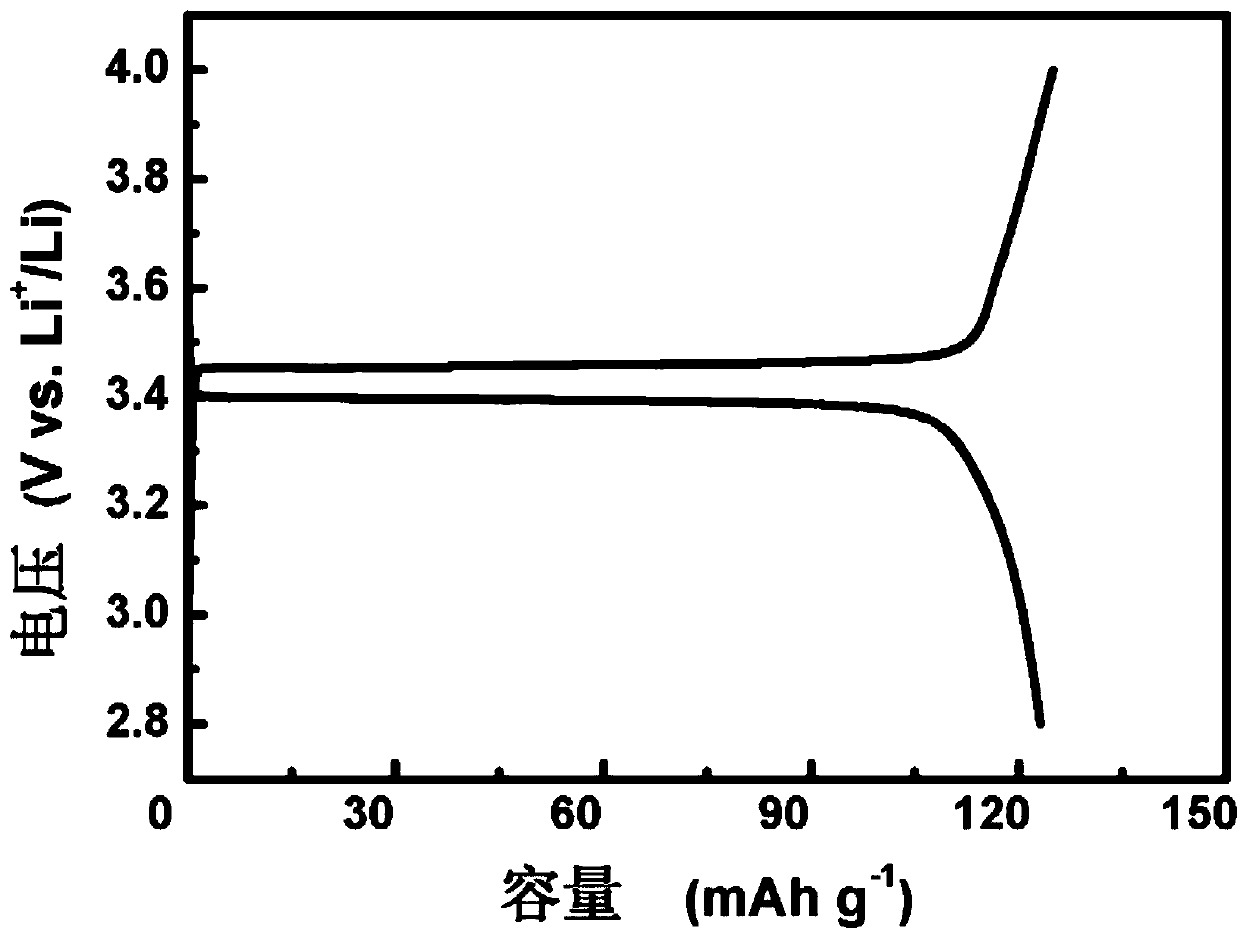

A lithium-ion battery and solid-state electrolyte technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of poor interface performance and low conductivity of all-solid-state lithium-ion batteries, and achieve industrial applications. The preparation process is simple and the effect of good charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 2g of lithium iron phosphate electrode material, 0.25g of acetylene black, 0.25g of polyvinylidene fluoride in 12ml of N-methylpyrrolidone 300r / min ball mill for 24h, mix evenly and coat on aluminum foil. Vacuum-dried at 80°C for 12 hours to obtain a positive electrode sheet.

[0028] (2) Take 2g of polyacrylonitrile powder, 0.05g of lithium perchlorate, and 0.1g of aluminum oxide particles and add them to 20ml of dimethylformamide and stir for 20 hours to obtain a uniform mixed solution, and then pour it into a polytetrafluoroethylene mold , vacuum drying at 25 °C for 12 h to obtain a composite solid electrolyte.

[0029] (3) Put the composite solid electrolyte on the positive electrode sheet, and heat press at 30° C. for 6 hours with a hot press to obtain an integrated positive electrode solid electrolyte structure.

[0030] (4) Assemble the all-solid-state lithium-ion battery in the following form: positive electrode case-spring leaf-stainless steel gasket-...

Embodiment 2

[0033] (1) Take 1g of lithium cobalt oxide electrode material, 0.9g of carbon nanotubes, 0.6g of polyvinylidene fluoride in 10ml of N-methylpyrrolidone 300r / min ball mill for 24h, mix them evenly and coat them on aluminum foil. Vacuum-dried at 80°C for 12 hours to obtain a positive electrode sheet.

[0034] (2) Take 2g of polyacrylonitrile powder, 0.06g of lithium perchlorate, and 0.8g of aluminum oxide particles and add them to 20ml of dimethylformamide and stir for 20 hours to obtain a uniform mixed solution, and then pour it into a polytetrafluoroethylene mold , vacuum drying at 40 °C for 42 h to obtain a composite solid electrolyte.

[0035] (3) Put the composite solid electrolyte on top of the positive electrode sheet, and press it with a hot press at 90°C for 15 hours to obtain an integrated structure of the positive electrode solid electrolyte

[0036] (4) Assemble the all-solid-state lithium-ion battery in the following form: positive electrode case-spring leaf-stainl...

Embodiment 3

[0039] (1) Take 1.5g of nickel-cobalt lithium manganate electrode material, 0.7g of graphene, 0.3g of polyvinylidene fluoride in 10ml of N-methylpyrrolidone 300r / min ball mill for 24h, mix evenly and coat on aluminum foil. Vacuum-dried at 80°C for 12 hours to obtain a positive electrode sheet.

[0040] (2) Take 2g of polyacrylonitrile powder, 0.1g of lithium perchlorate, and 0.4g of aluminum oxide particles and add them to 20ml of dimethylformamide and stir for 20 hours to obtain a uniform mixed solution, and then pour it into a polytetrafluoroethylene mold , vacuum drying at 40 °C for 42 h to obtain a composite solid electrolyte.

[0041] (3) Put the composite solid electrolyte on top of the positive electrode sheet, and use a hot press at 90°C for 24 hours to obtain an integrated positive electrode solid electrolyte structure

[0042] (4) Assemble the all-solid-state lithium-ion battery in the following form: positive electrode case-spring leaf-stainless steel gasket-positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com