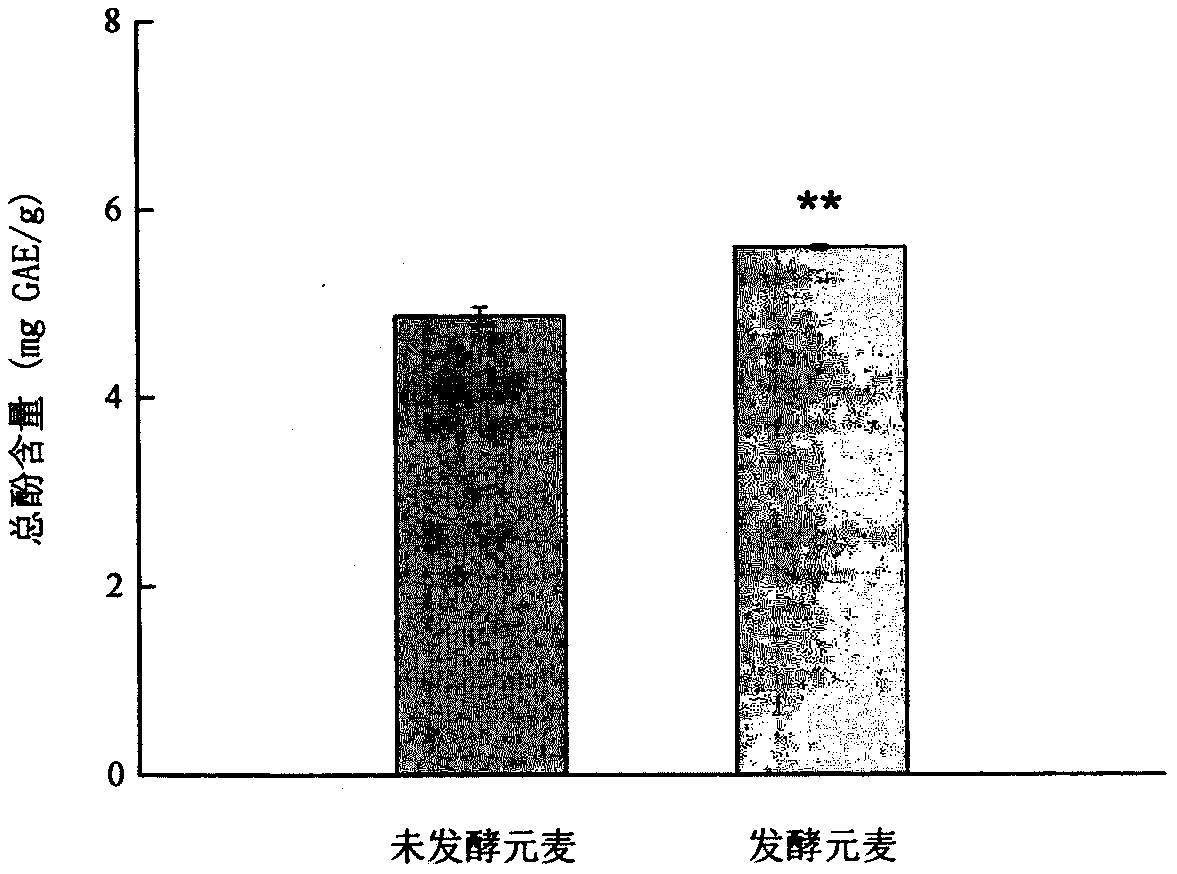

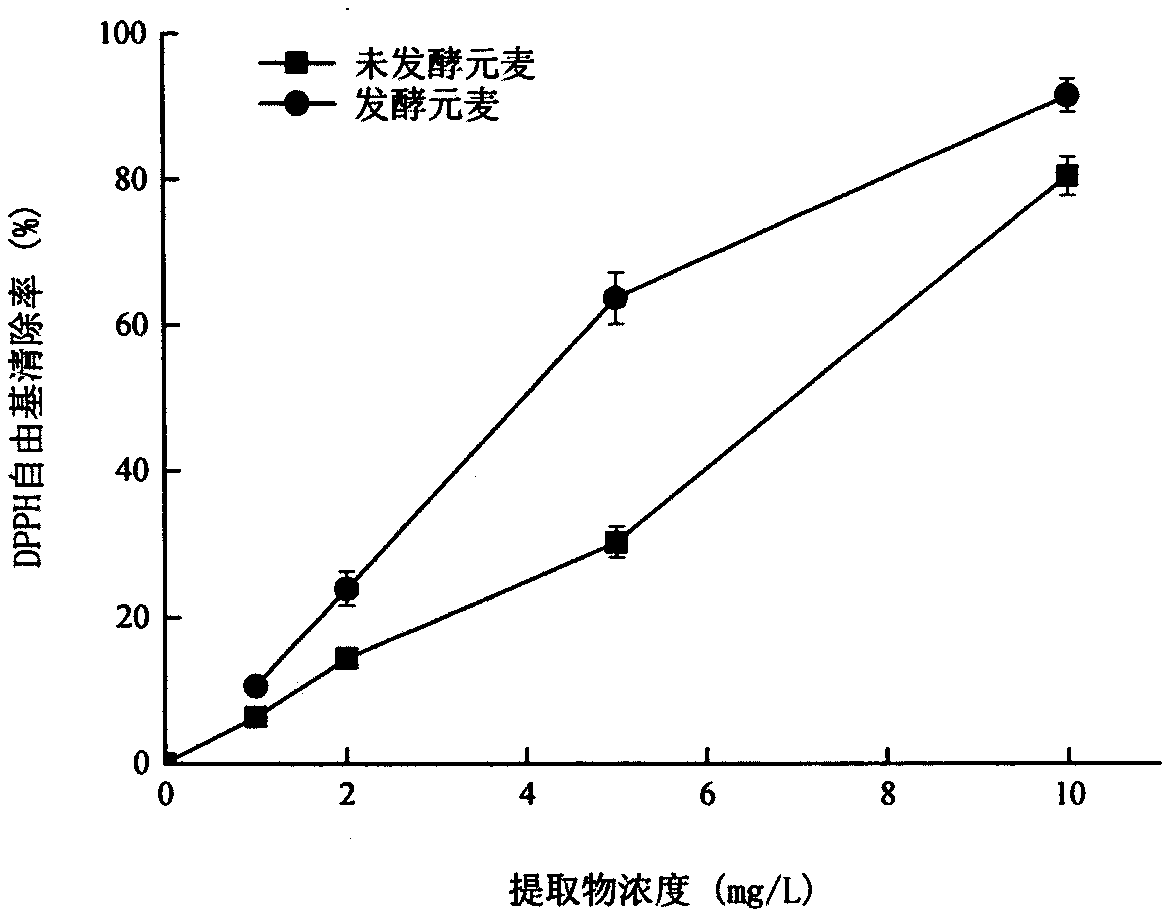

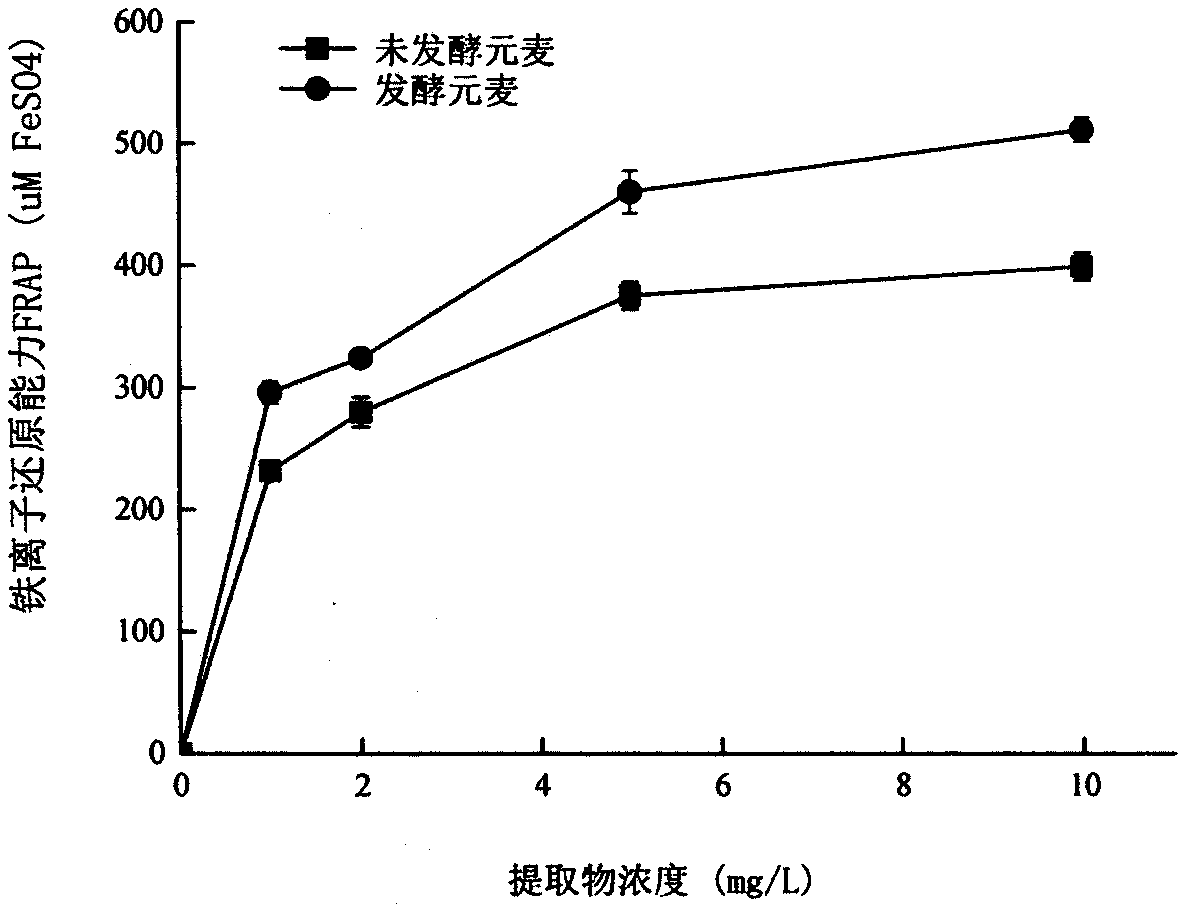

Method for enriching highland barley polyphenol through fermentation of lactic acid bacteria and preparing antioxidants

A lactic acid bacteria fermentation and antioxidant technology, which is used in food ingredients as antioxidants, food ingredients containing natural extracts, food science, etc., to achieve the effects of wide planting range, high antioxidant activity, and low development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0042] Pick the full-grained, washed and dried Yuanmai kernels, crush them and pass through a 60-mesh sieve to obtain Yuanmai powder, weigh the sample, add water at a ratio of 1:10, and autoclave at 121°C for 20 minutes to obtain Yuanmai emulsion. Put Lactobacillus plantarum B1-6 cryopreservation tube directly into MRS liquid medium, culture at 37°C for 48h, then add 3% into fresh MRS liquid medium for secondary activation, and cultivate at 37°C for 24h. The secondary activated culture solution was added to the above-mentioned barley emulsion with a 3% inoculation amount, and cultured at 37° C. for 36 hours to obtain fermented barley milk. Add 60% ethanol-water solution to the fermented barley milk at a ratio of 1:10, mix thoroughly, ultrasonicate for 4 hours in a water bath at 40°C, then centrifuge at 5000 rpm / min for 5 minutes, repeat the extraction 3 times, and collect the supernatant. The extract was concentrated by rotary evaporation at 40°C and 120 rpm / min, and the volum...

Embodiment example 2

[0045] Pick the full-grained, washed and dried Yuanmai kernels, crush them and pass through a 60-mesh sieve to obtain Yuanmai powder, weigh the sample, add water at a ratio of 1:10, and autoclave at 121°C for 20 minutes to obtain Yuanmai emulsion. Put Lactobacillus plantarum B1-6 cryopreservation tube directly into MRS liquid medium, culture at 37°C for 48h, then add 3% into fresh MRS liquid medium for secondary activation, and cultivate at 37°C for 24h. The secondary activated culture solution was added to the above-mentioned barley emulsion with a 3% inoculation amount, and cultured at 37° C. for 36 hours to obtain fermented barley milk. Add 60% ethanol-water solution to the fermented barley milk at a ratio of 1:10, mix thoroughly, ultrasonicate for 4 hours in a water bath at 40°C, then centrifuge at 5000 rpm / min for 5 minutes, repeat the extraction 3 times, and collect the supernatant. The extract was concentrated by rotary evaporation at 40° C. and 120 rpm / min. Add a smal...

Embodiment example 3

[0050] Dissolve the fermented barley extract and pre-fermented barley extract obtained in Example 2 in sterile water to make a solution with a concentration of 1-10 mg / L, pass through a 0.22 μm sterile filter membrane, and set aside. Take out the cryopreservation tube of human liver cancer HepG2 cells stored at -80°C, shake gently in a 37°C water bath, transfer to a centrifuge tube after melting, add 2mL containing 100U / mL penicillin, 0.1mg / mL streptomycin, 1% 1mol / Dulbecco's Modified Eagle's Medium-high glucose (DMEM) medium in L Heps buffer, centrifuge at 1000rpm / min for 5min, discard the supernatant, then add 5mL of the above medium containing 20% fetal bovine serum, pipette evenly, and transfer the cells Suspension to the bottom area is 25-75cm 2 The cell culture flasks were placed in a constant temperature incubator at 37°C and a carbon dioxide concentration of 5% for cultivation. When the cells grow to 70-90% of the bottom area of the bottle, add 3 mL of trypsin to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com