Biodegradable flame retardant protective suit fabric and padding solution

A biodegradable, protective clothing technology, applied in the direction of flame retardant fibers, improved hand fibers, fiber types, etc., can solve the problem that aramid fabrics cannot adopt environmental protection methods, etc., to reduce the risk of secondary contamination, reduce the risk of leakage, The effect of saving processing money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

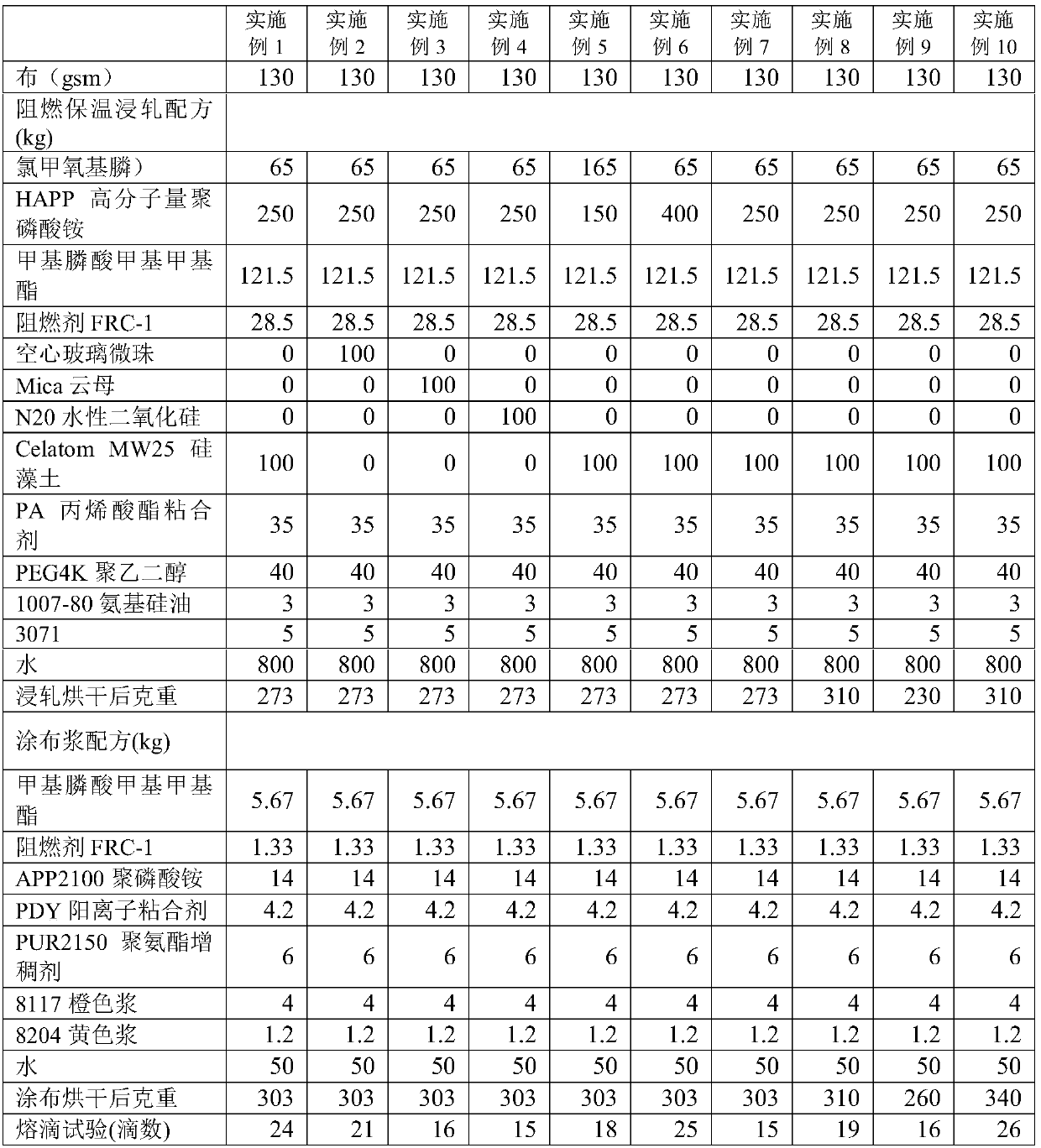

Embodiment 1

[0078] Take by weighing 65kg of flame retardant chlorine (diisopropylamino) methoxyphosphine, 250kg of high molecular weight ammonium polyphosphate with a polymerization degree of more than 2000, and 150kg of composite phosphorus-containing flame retardant (wherein: methylphosphonic acid (5-ethyl -2-methyl-2-oxo-1,3,2-dioxaphosphorin-5-yl)methyl methyl ester 121.5kg, flame retardant FRC-1 (CAS No.42595-45- 9) 28.5kg), CelatomMW25 diatomite 100kg, acrylate adhesive 35kg, PEG4K polyethylene glycol 40kg, amino silicone oil 3kg, polyoxyethylene ether wetting agent 5kg, water 800kg. The above materials are dispersed into a milky white suspension through the high-speed rotating impeller on the high-speed disperser, and then added to the padding tank. There is a stirring device in the padding tank, which continuously stirs the added materials to avoid material sedimentation.

[0079] Get 130gsm polyvinyl alcohol high-temperature water-soluble spunlace nonwoven fabric, after padding ...

Embodiment 2

[0097] The Celatom MW25 diatomite in the above-mentioned Example 1 was replaced with hollow glass microspheres of the same amount, and the rest of the proportions remained unchanged. Stir quickly in the padding tank to prevent the glass beads from floating on the liquid surface and the solid flame retardant powder from settling.

[0098] The fabric was produced by the same process as in Example 1, and tested according to the ISO9150 standard, the number of molten droplets was 21.

Embodiment 3

[0100] The Celatom MW25 diatomaceous earth in the above-mentioned embodiment 1 was replaced with the same amount of mica powder, and the remaining proportions remained unchanged. Stir quickly in the padding tank to prevent the solid flame retardant powder from settling.

[0101] The fabric was produced by the same process as in Example 1, and tested according to the ISO9150 standard, the number of molten droplets was 16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com