Manufacturing method of silicon detector array device for enhancing blue light efficiency

A detector array and manufacturing method technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low blue light sensitivity, achieve uniform electric field distribution, improve quantum efficiency, and reduce photosensitive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

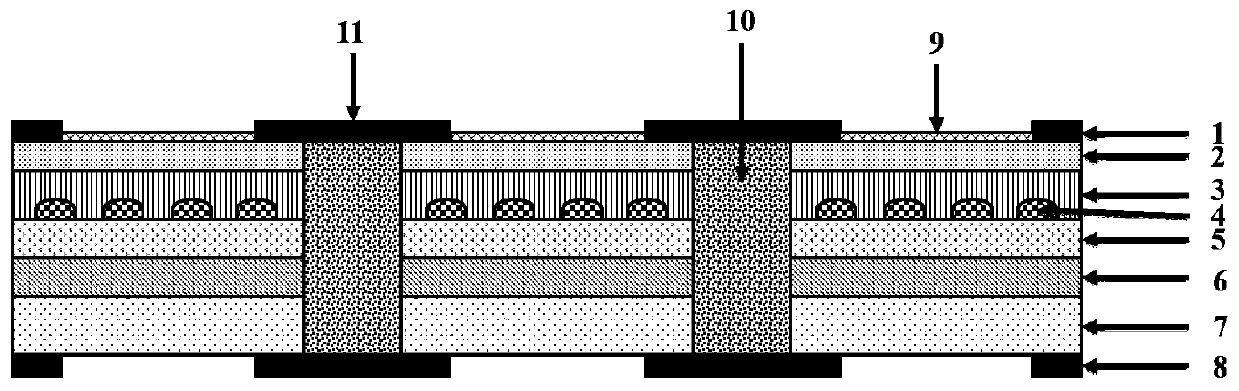

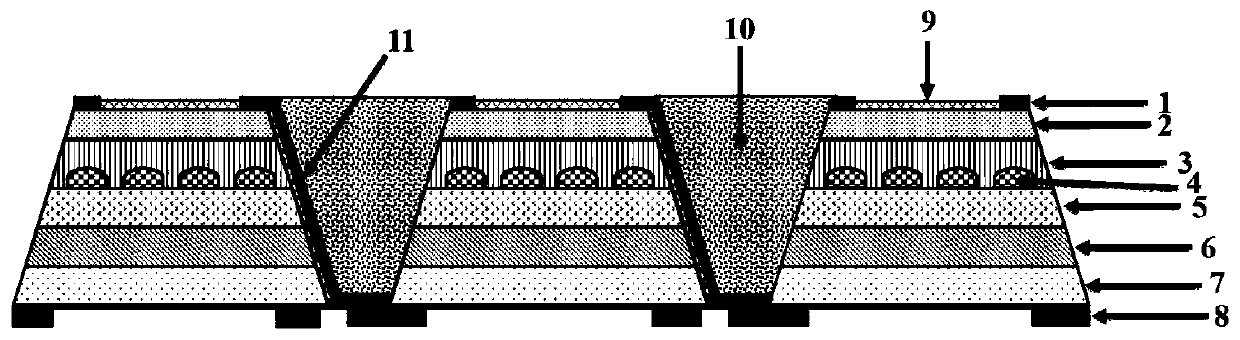

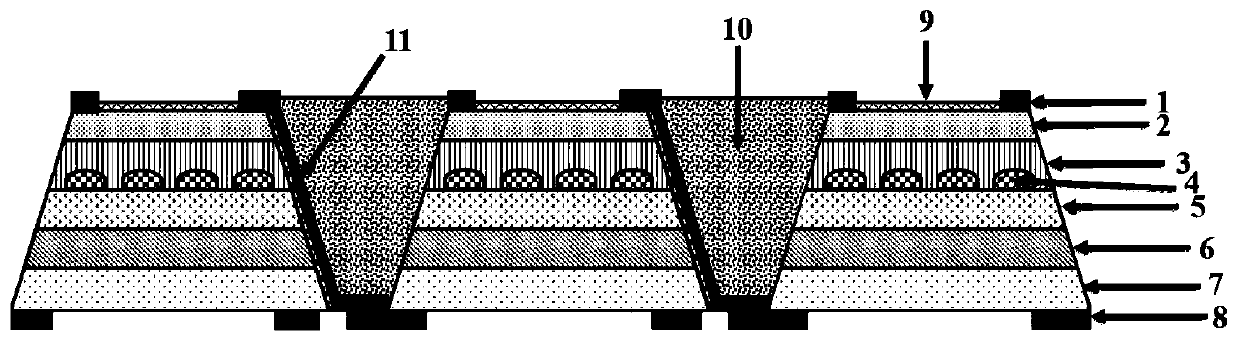

[0059] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. This embodiment is described with reference to FIG. 1 to FIG. 5 . The silicon detector array device with enhanced blue light efficiency provided by this embodiment includes a plurality of detection units, a plurality of isolation regions 10 and a plurality of electrode leads 11 .

[0060] Among them, a plurality of detection units are regularly arranged to form an array, and each detection unit includes an anode 1, a non-depletion layer 2, an absorption layer 3, a field control layer 5, an avalanche layer 6, a substrate layer 7, a cathode 8 and a light-transmitting layer 9. The field control layer 5 , the absorption layer 3 and the non-depletion layer 2 are sequentially arranged on the upper surface of the avalanche layer 6 from bottom to top. A doped junction 4 is provided inside the absorption layer 3 , the lower surface of the doped junction 4 is in contact with the upper surface of the field control layer 5 , and t...

specific Embodiment approach 2

[0067] Specific embodiment 2. For the parallel electrode structure array device, and the light-transmitting layer 9 and the anode 1 are all located on the same plane, the combination Image 6 To illustrate the present embodiment, the basic process steps are as follows:

[0068] Step 1. Select a highly doped n+ type silicon wafer as the substrate material of the array device, and perform cleaning treatment; the impurities are pentavalent elements such as P and As.

[0069] Step 2. Deposit a silicon epitaxial layer on the substrate material by techniques such as vapor phase epitaxy (VPE) or molecular beam epitaxy (MBE), as the p+ type avalanche layer 6 of the array device; the grown epitaxial material has low doping concentration and low defect of silicon.

[0070] Step 3: growing a p+-type Si-based field control layer 5 on the avalanche layer 6 by vapor phase epitaxy or molecular beam epitaxy.

[0071] Step 4: After the field control layer 5 is prepared, a p-type Si-based abs...

specific Embodiment approach 3

[0089] Specific embodiment 3. The manufacturing process for the situation where part of the lower surface of the light-transmitting layer 9 of the silicon detector array device for enhancing blue light efficiency is in contact with the non-depletion layer 2, and the remaining part is in contact with the upper surface of the anode 1: Step 14 and Step 15 in the specific embodiment 2 are combined and changed to: prepare an anti-reflection film with a thickness of about 0.1-5 μm on the upper surface of the non-depleted layer 2 and the anode 1 by low-temperature evaporation method as an array device The transparent layer 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com