Preparation method of semi-aromatic polythioesters

A polythioester and semi-aromatic technology, which is applied in the field of preparation of semi-aromatic polythioester, can solve the problems of unsuitability for large-scale production and high energy consumption of the synthesis route, and achieve the improvement of mechanical properties and optical properties, The effect of mild reaction conditions and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

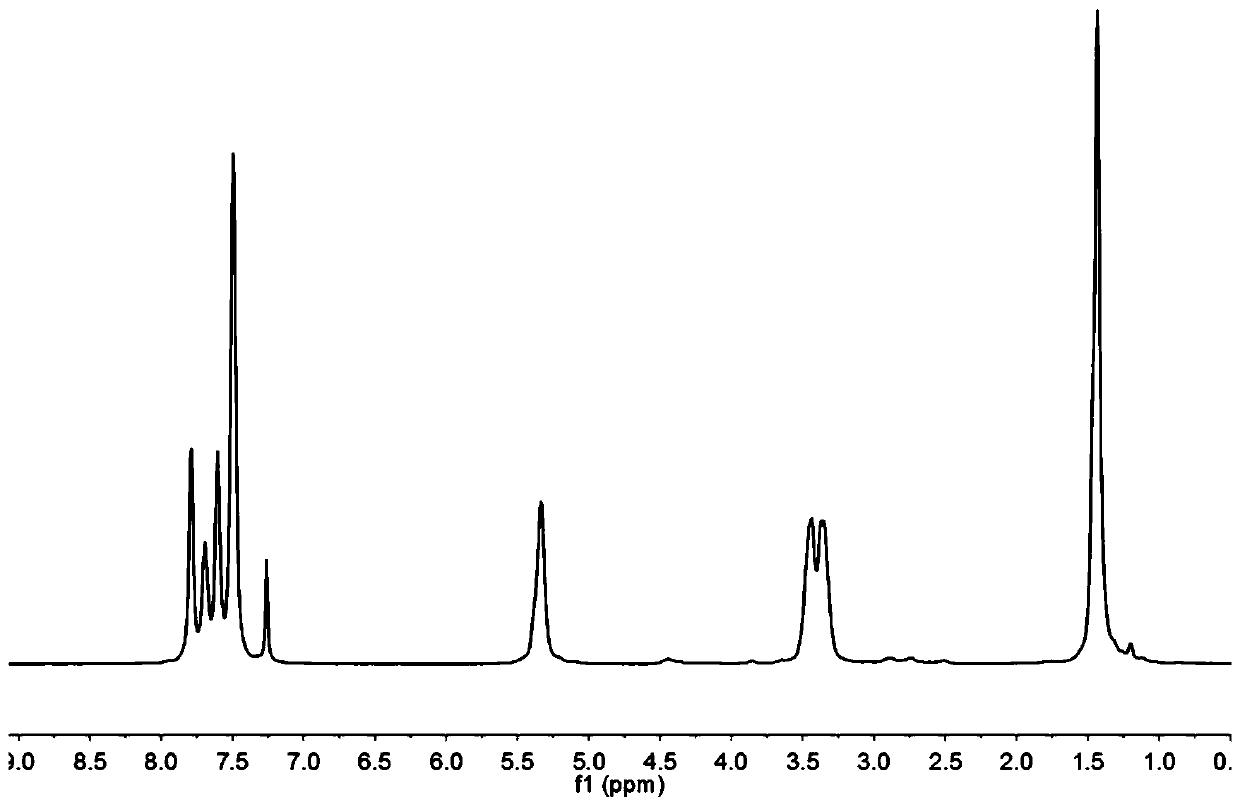

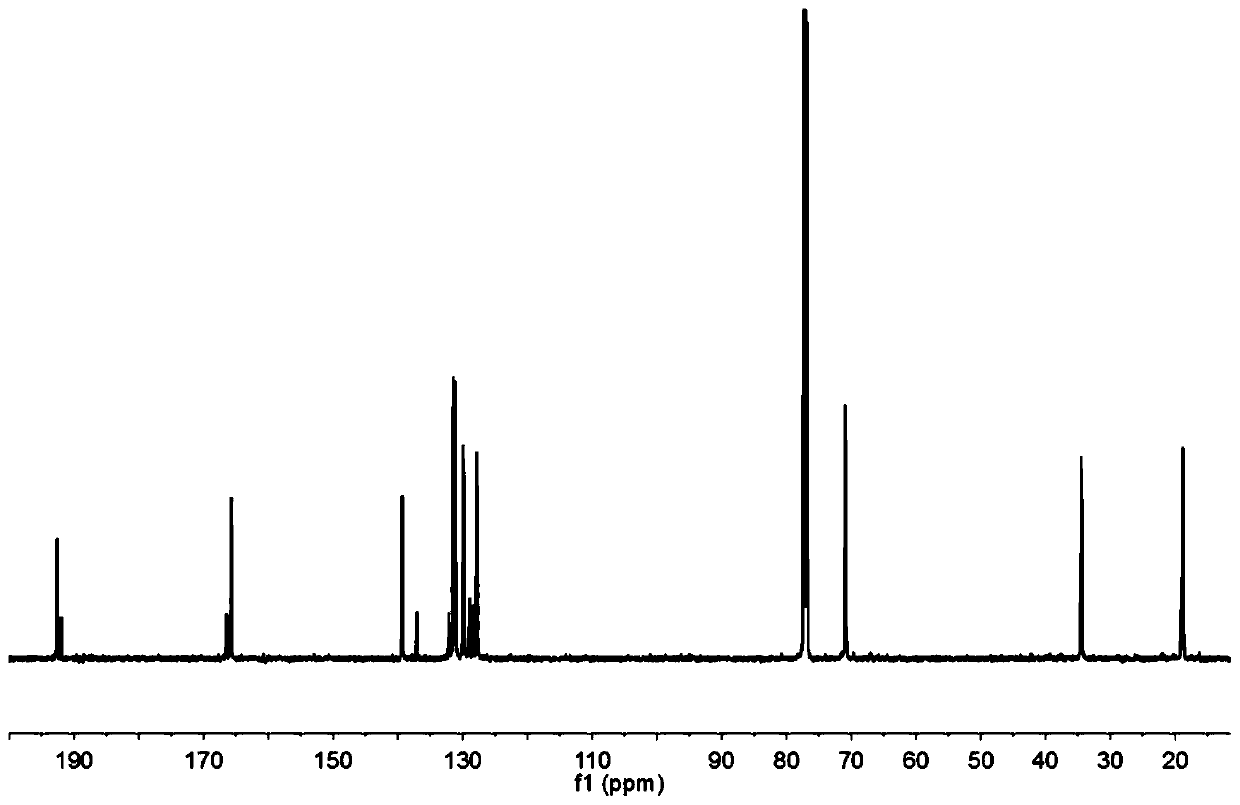

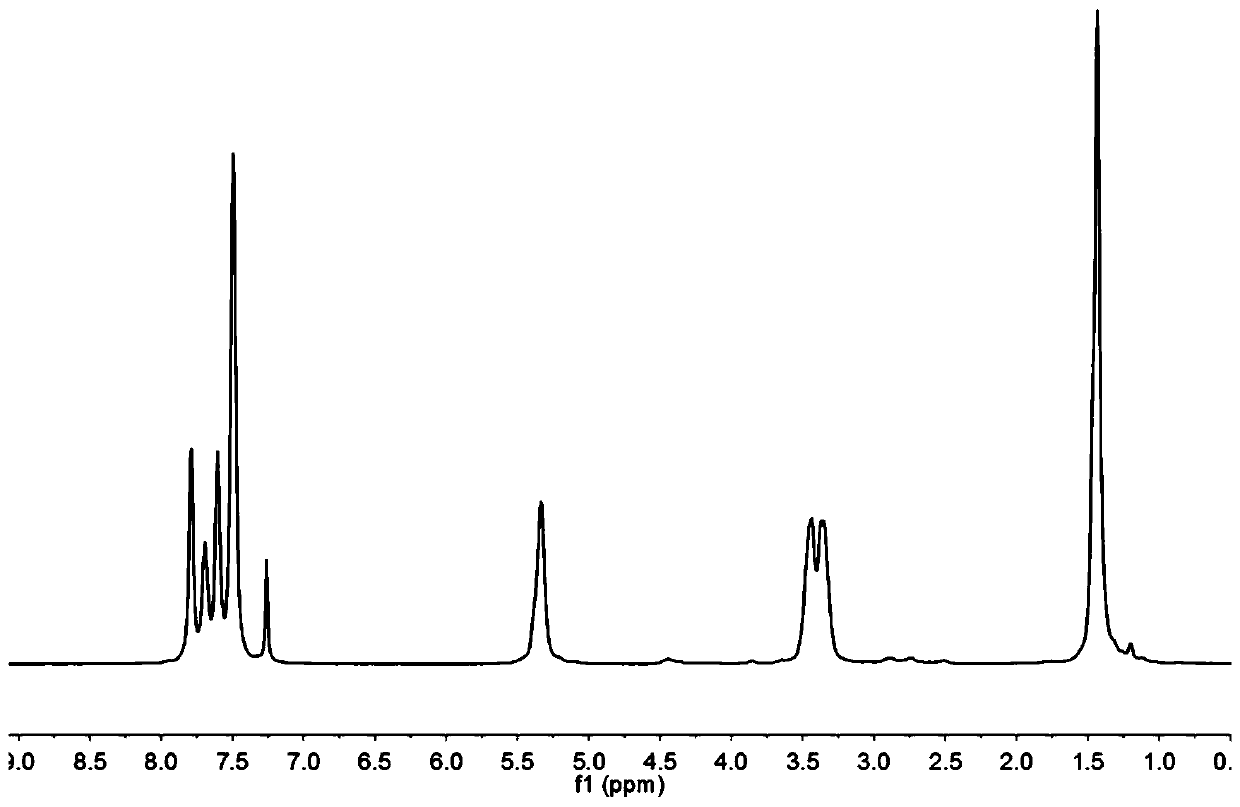

[0033] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under nitrogen protection, a certain amount of catalyst 3a and cocatalyst bis(triphenylphosphoryl)ammonium chloride were weighed at room temperature, and the molar ratio of catalyst to cocatalyst was 1 / 1. Then add alkylene oxide 1a and thioanhydride 2a, the molar ratio of epoxy hydrocarbon, thioanhydride and chromium metal catalyst is 2000 / 1000 / 1. It was then placed in an oil bath at 25°C and magnetic stirring was started. Reaction 4h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 35600 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude...

Embodiment 2

[0035] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under nitrogen protection, a certain amount of catalyst 3a and cocatalyst bis(triphenylphosphoryl)ammonium chloride were weighed at room temperature, and the molar ratio of catalyst to cocatalyst was 1 / 2. Then add alkylene oxide 1b and thioanhydride 2a, the molar ratio of alkylene oxide, thioanhydride and chromium metal catalyst is 2000 / 1000 / 1. Then put it into an oil bath at 50°C and start magnetic stirring. Reaction 16h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 41200 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude product in a...

Embodiment 3

[0037] Dry the 100mL pressure-resistant glass bottle equipped with a magnet at 130°C for more than 12 hours, vacuumize it until it cools down to room temperature, and flush it with nitrogen to prepare for use. Under nitrogen protection, a certain amount of catalyst 3a and cocatalyst bis(triphenylphosphoryl)ammonium chloride were weighed at room temperature, and the molar ratio of catalyst to cocatalyst was 1 / 2. Then add alkylene oxide 1c and thioanhydride 2a, the molar ratio of alkylene oxide, thioanhydride and chromium metal catalyst is 2000 / 1000 / 1. Then put it into an oil bath at 10°C and start magnetic stirring. Reaction 2h, stop stirring. A very small amount of the reaction mixture was removed for the 1 H NMR and GPC tests. 1 H NMR test showed that the conversion rate of thioanhydride was >99%, and GPC test showed that the polymer molecular weight was 37800 g / mol. Purify the remaining reaction polymer. Purification of the polymer: first dissolve the crude product in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com