Method for preparing laminaribiose

A technology of laminadisaccharide and identity, which is applied in the field of in vitro enzymatic preparation of laminadisaccharide, can solve the problem of high cost of separation, and achieve the effect of improving conversion efficiency and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 In vitro multi-enzyme catalyzed conversion of starch and glucose into laminaribiose

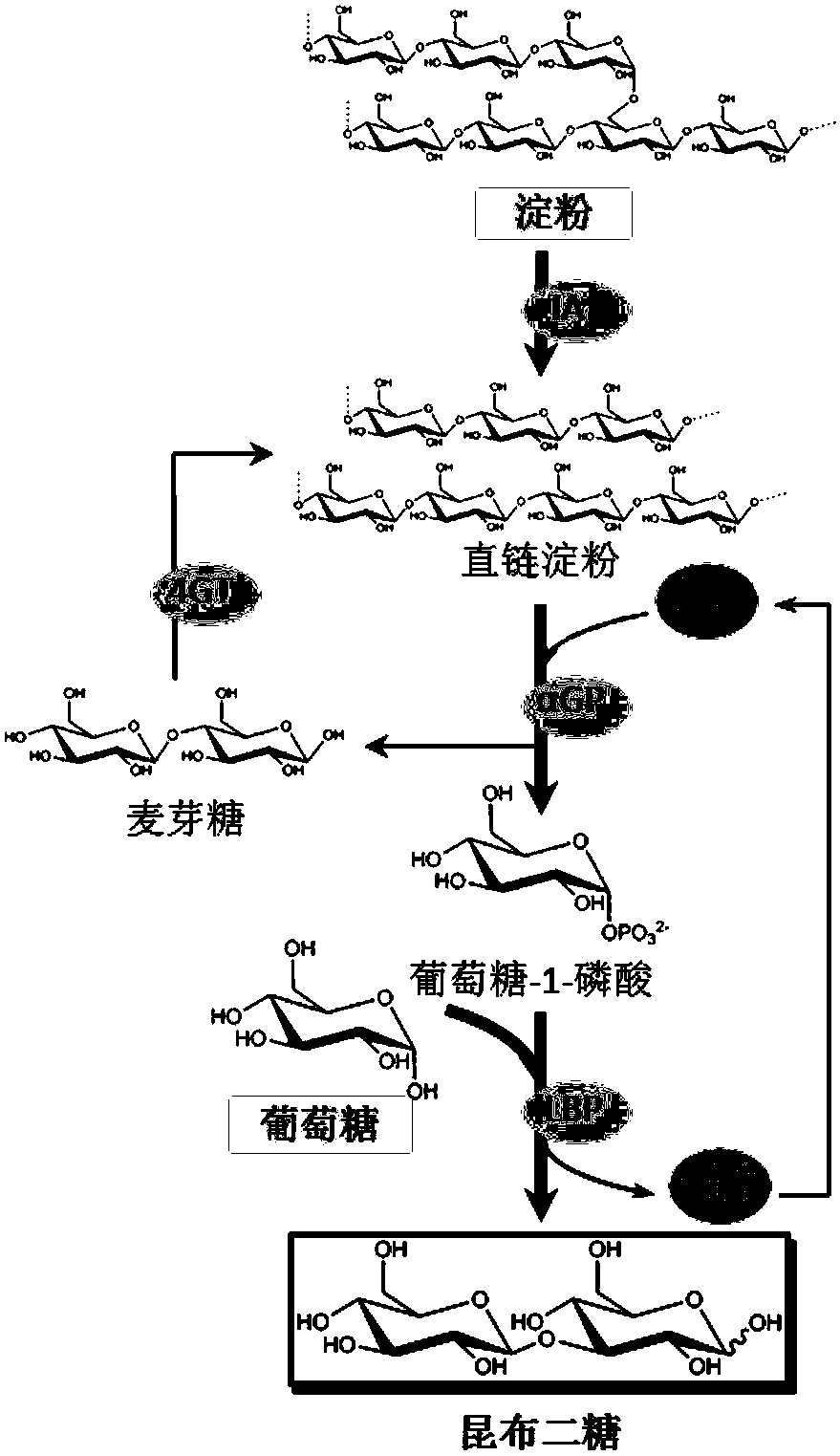

[0050] The catalytic pathway for the conversion of starch and glucose to laminaribiose by a multi-enzyme catalytic system in vitro see figure 1 . The key enzymes involved include: (1) starch phosphorylase (αGP, EC 2.4.1.1), which is used to release glucose-1-phosphate from starch; (2) laminaribiose phosphorylase (LBP, EC 2.4 .1.31), used to catalyze the formation of laminaribiose from glucose-1-phosphate and glucose.

[0051] In this example, starch phosphorylase is derived from Thermotoga maritima, and its gene number on KEGG is TM1168; laminaribiose phosphorylase is derived from Paenibacillus sp., and its gene is in The number on KEGG is BAJ10826, and these genomic DNAs can be obtained from the official website of ATCC (www.atcc.org). 这两个基因分别用F1 / R1和F2 / R2从相应的基因组DNA中通过PCR获取,其中,F1:GTTTAACTTTAAGA AGGAGATATAGTGCTGGAGAAACTTCCCGAG,R1:GTGGTGGTGGTGGTGCTCGAGTCAGAGAACCTTCTTCCAGAC,F2...

Embodiment 2

[0055] Example 2 Improve the yield of laminaribiose by adding enzymes that promote starch hydrolysis

[0056] Starch phosphorylase cannot completely hydrolyze starch, and adding isoamylase (IA, EC 3.2.1.68) which can help hydrolyze starch in the reaction system can increase the yield of laminaribiose.

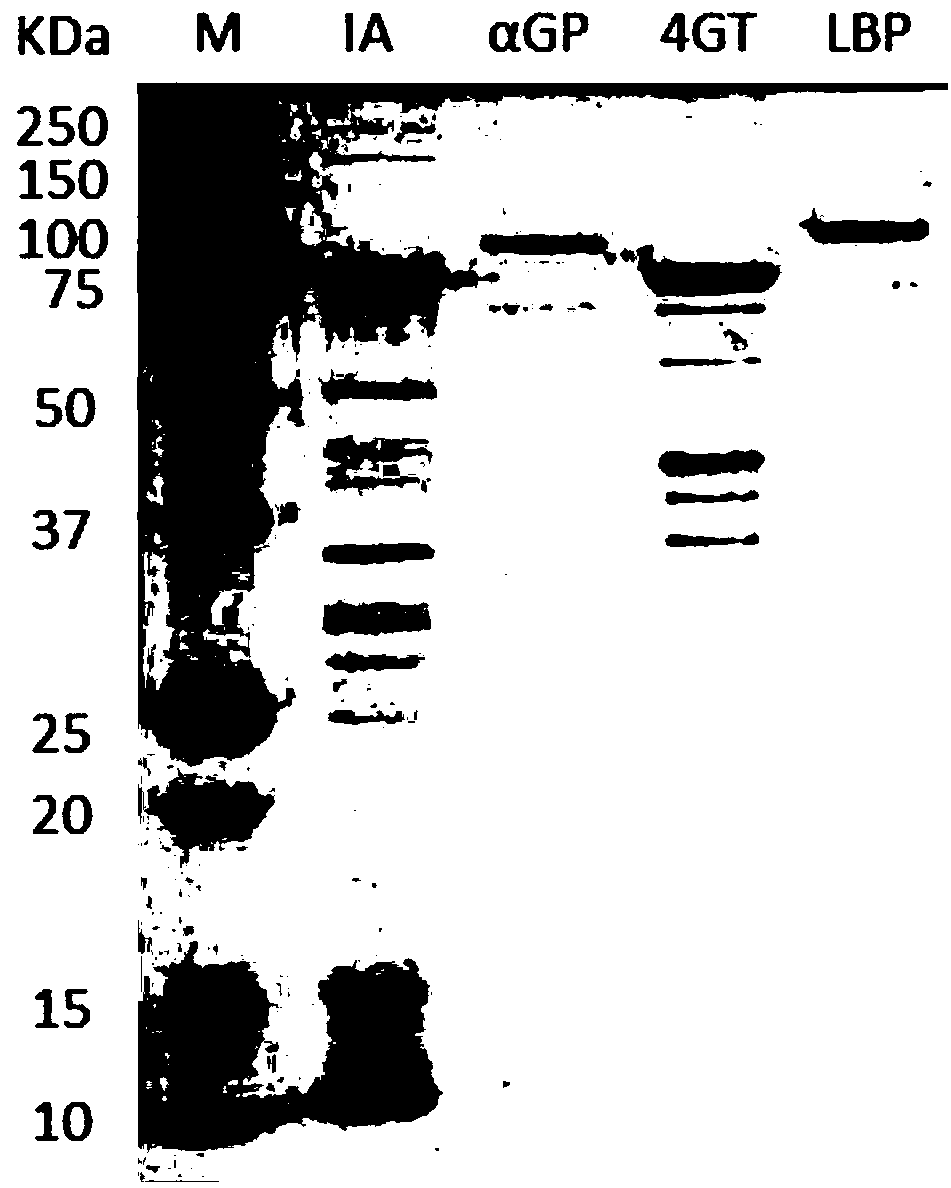

[0057] In this example, the isoamylase is derived from Sulfolobus tokodaii, whose gene number on KEGG is ST0928, and the genomic DNA of this strain is purchased from DSMZ, the German Culture Collection. This gene was obtained from the corresponding genomic DNA by PCR with primers F3 / F4, wherein, F3: GTTTAACTTTAAGAAGGAGATATAATGGTTTTTTCACAAGGATAGA CC, R: GTGGTGGTGGTGGTGGTGCTCGAGCTAATATTCAATCCTCCTATAT ACC, and cloned into pET20b vector by Simple Cloning method to obtain the corresponding expression vector pET20b-StIA. Then, this plasmid is transformed into Escherichia coli expression strain BL21 (DE3), carries out protein expression and purification, and the result of protein purifi...

Embodiment 3

[0062] Example 3 By optimizing the reaction conditions, the yield of laminaribiose was further improved

[0063] The preparation of isoamylase, starch phosphorylase and laminaribiose phosphorylase is the same as in Example 1 and Example 2.

[0064] Contain 5mM sodium acetate buffer solution (pH 5.5), 0.5mM divalent magnesium ion, 1U isoamylase, 10mg starch in a 1.0mL reaction system, carry out catalytic reaction at 85 ℃, reaction time is 12 hours.

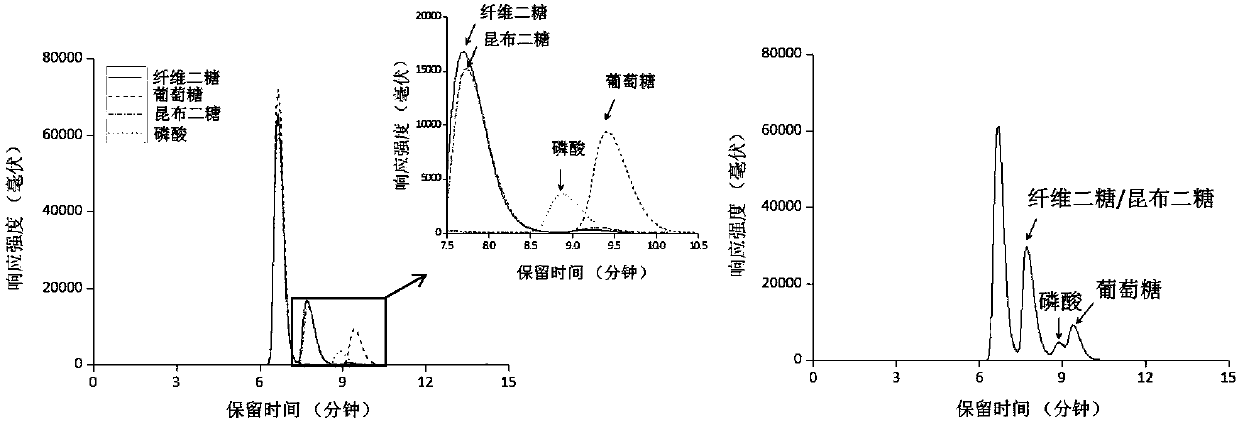

[0065] Then in a 1.0mL reaction system containing 100mM HEPES buffer (pH 7.0), 5mM divalent magnesium ions, 10mM potassium phosphate (pH 7.0), 1U starch phosphorylase, 1U laminaribiose phosphorylase, 10mg The IA-treated starch and different concentrations of glucose (60-150 mM) were catalyzed at 50° C. for 24 hours. The detection of laminaribiose is the same as in Example 1. The result is as Figure 5A , as the glucose concentration increases, the production of laminaribiose increases, but after the glucose concentration is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com