Black arsenic-phosphorus crystal and preparation method thereof

A technology of crystals and mixed materials, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of harsh growth equipment conditions, low growth temperature, high impurity content, etc., to expand the band gap change and application range , The effect of simple growth equipment and improved transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As an aspect of the technical solution of the present invention, what it relates to is a method for preparing black arsenic phosphorus crystals, comprising the following steps:

[0027] (1) Mix the mixture of arsenic and phosphorus, tin powder and tin tetraiodide according to the mass ratio of 10~60:1~3:0.5~1.5, then vacuum seal, then heat the mixed material to 700℃~800℃ and keep it for 2~3h ;

[0028] (2) Cool the final mixed material obtained in step (1) to a temperature of 450-550°C and keep it for 3-4 hours;

[0029] (3) Cool the final mixed material obtained in step (2) to room temperature to obtain black arsenic phosphorus crystals.

[0030] In some embodiments, the step (1) includes: vacuum-packing the mixed material in a quartz tube, and then putting it into a heating furnace for heating.

[0031] Among them, a molecular pump unit and a hydrogen-oxygen flame can be used to vacuum-pack the mixed material in a quartz tube, and then place the quartz tube in the h...

Embodiment 1

[0049] Put a mixture of high-purity gray arsenic and red phosphorus crystals with an atomic ratio of 0.5:0.5, tin powder, and tin tetraiodide in a mass ratio of 25:1:0.6 into a quartz tube with an outer diameter of 10 mm and a wall thickness of 1 mm. Molecular pump unit and oxyhydrogen flame vacuum seal the quartz block to 10 -2 Pa, the content of the mixed ingredients in the quartz tube is 15~30mg / cm 3 ;

[0050] Put the sealed quartz tube horizontally into the heating zone of the tube furnace, set the temperature in the furnace, first heat the furnace to 750°C at a speed of 5°C / min, and keep it at 750°C for 3 hours, then after 5 hours The furnace was internally cooled to 500°C and held at this temperature for an additional 4 hours.

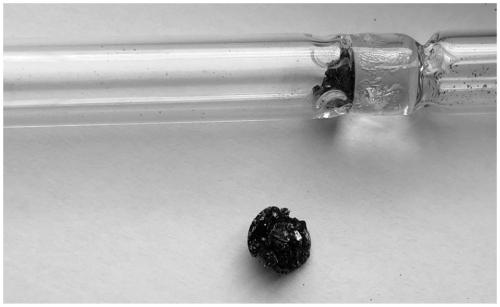

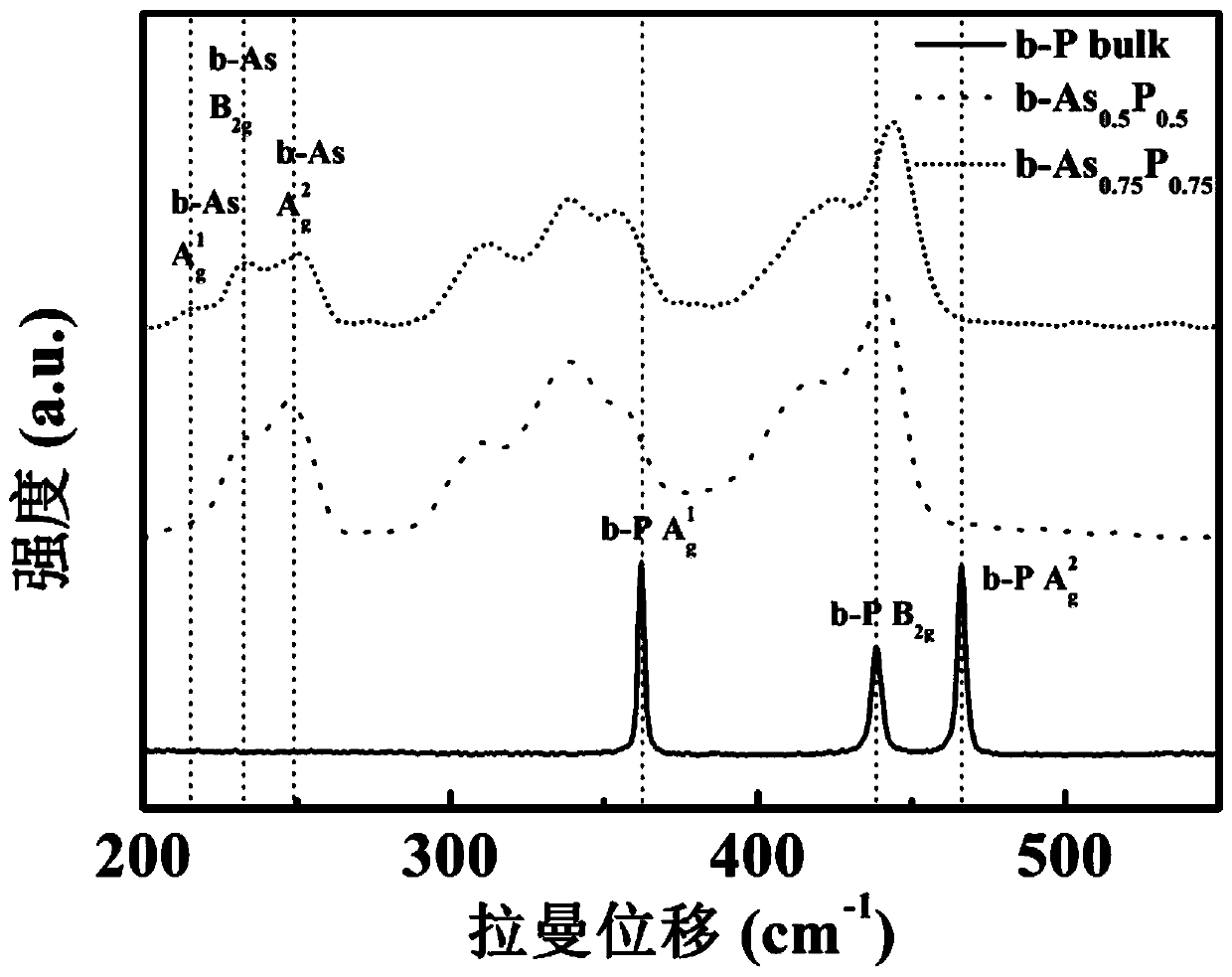

[0051] This was followed by further slow cooling to room temperature over 3 hours. Black arsenic phosphorus crystal b-As can be obtained at the cold end of the quartz glass tube 0.5 P 0.5 ,Such as figure 1 shown.

Embodiment 2

[0053] Put high-purity gray arsenic and red phosphorus crystals with an atomic ratio of 0.83:0.17, tin powder, and tin tetraiodide in a mass ratio of 30:2:1.5 into a quartz tube with an outer diameter of 15 mm and a wall thickness of 1.5 mm. The pump unit and oxyhydrogen flame vacuum seal the quartz block to 10 -2 Pa, the content of the mixed ingredients in the quartz tube is 15~30mg / cm 3 ;

[0054] Put the sealed quartz tube horizontally into the heating zone of the muffle furnace, set the temperature in the furnace, first heat the furnace to 750°C at a speed of 4°C / min, keep it at 750°C for 3 hours, and then heat it up for 7 hours The furnace was internally cooled to 500°C and held at this temperature for an additional 4 hours.

[0055] This was followed by further slow cooling to room temperature over 5 hours. Black arsenic phosphorus crystal b-As can be obtained at the cold end of the quartz glass tube 0.83 P 0.17 ,Such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com