Solid waste recycling treatment system and method for aluminum electrolysis cell

A solid waste and aluminum electrolytic cell technology, applied in the direction of solid waste removal, etc., can solve problems such as low fluoride recovery rate, waste of fluorine resources, and limitation of additive usage, so as to shorten leaching time, reduce production investment, and leaching efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

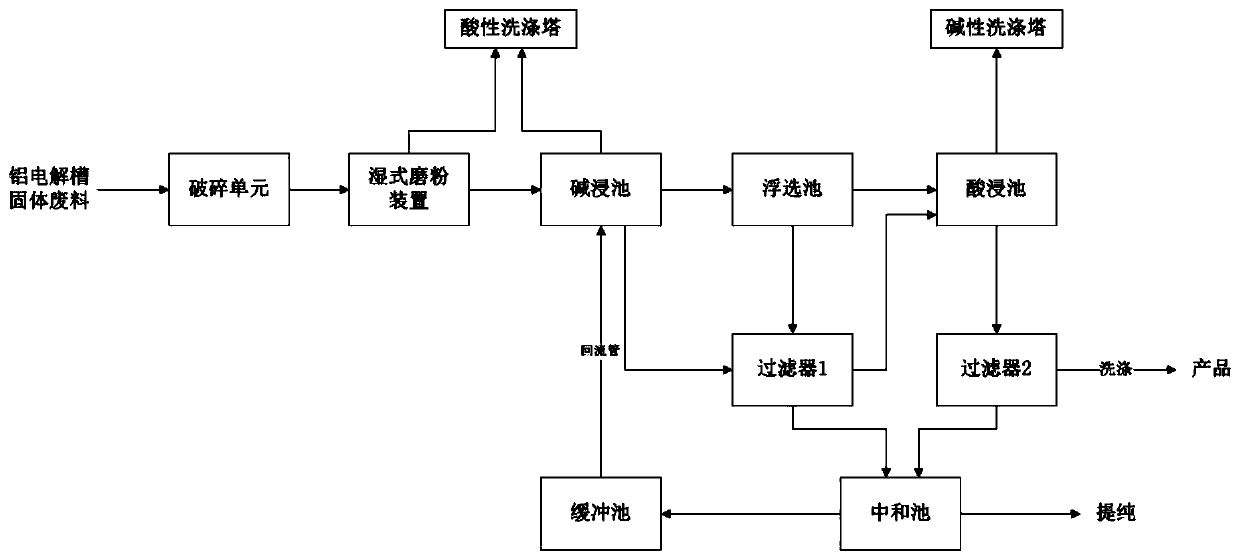

[0030] The solid waste of an aluminum electrolytic cell in a certain factory is manually screened to initially separate the waste cell lining from the anode carbon slag and the waste cathode carbon block, according to figure 1 The flow of the processing system is shown for processing:

[0031] 1. Treatment of anode carbon slag and waste cathode carbon block

[0032] (1) The anode carbon slag and the spent cathode carbon block are initially crushed into particles with a particle size of less than 500 mm by the hammer crusher in the crushing unit, and then crushed to 80-100 mesh with a Raymond mill, with a mass percentage concentration of 10% NaOH aqueous solution (or Ca(OH) 2 , CaO, KOH, Na 2 CO 3 、K 2 CO 3 Any one or more kinds of aqueous solutions) are mixed, put into a wet ball mill to grind to a particle size of ≤200 mesh, and then sent to an alkali immersion tank, and the gas generated by the wet mill is sent to an acid scrubber to be washed and discharged after reach...

Embodiment 2

[0045] The solid waste of an aluminum electrolytic cell in a certain factory is manually screened to initially separate the waste cell lining from the anode carbon slag and the waste cathode carbon block, according to figure 1 The flow of the processing system is shown for processing:

[0046] 1. Treatment of anode carbon slag and waste cathode carbon block

[0047] (1) The anode carbon slag and the spent cathode carbon block are initially crushed into particles with a particle size of less than 500 mm by the hammer crusher in the crushing unit, and then crushed to 80-100 mesh with a Raymond mill, with a mass percentage concentration of 12% KOH aqueous solution (or Ca(OH) 2 , CaO, NaOH, Na 2 CO 3 、K 2 CO 3 Any one or more kinds of aqueous solutions) are mixed, put into a wet ball mill to grind to a particle size of ≤200 mesh, and then sent to an alkali immersion tank, and the gas generated by the wet mill is sent to an acid scrubber to be washed and discharged after reach...

Embodiment 3

[0060] The solid waste of an aluminum electrolytic cell in a certain factory is manually screened to initially separate the waste cell lining from the anode carbon slag and the waste cathode carbon block, according to figure 1 The flow of the processing system is shown for processing:

[0061] 1. Treatment of anode carbon slag and waste cathode carbon block

[0062] (1) The anode carbon slag and the spent cathode carbon block are initially crushed into particles with a particle size of less than 500 mm by the hammer crusher in the crushing unit, and then crushed to 80-100 mesh with a Raymond mill, with a mass percentage concentration of 15% Na 2 CO 3 Aqueous solution (or Ca(OH) 2 , CaO, KOH, NaOH, K 2 CO 3 Any one or more kinds of aqueous solutions) are mixed, put into a wet ball mill to grind to a particle size of ≤200 mesh, and then sent to an alkali immersion tank, and the gas generated by the wet mill is sent to an acid scrubber to be washed and discharged after reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com