Oil-in-water type sun block and preparation method thereof

An oil-in-water, sunscreen lotion technology, applied in the field of sunscreen lotion, can solve the problems of greasy skin, high irritation, single effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

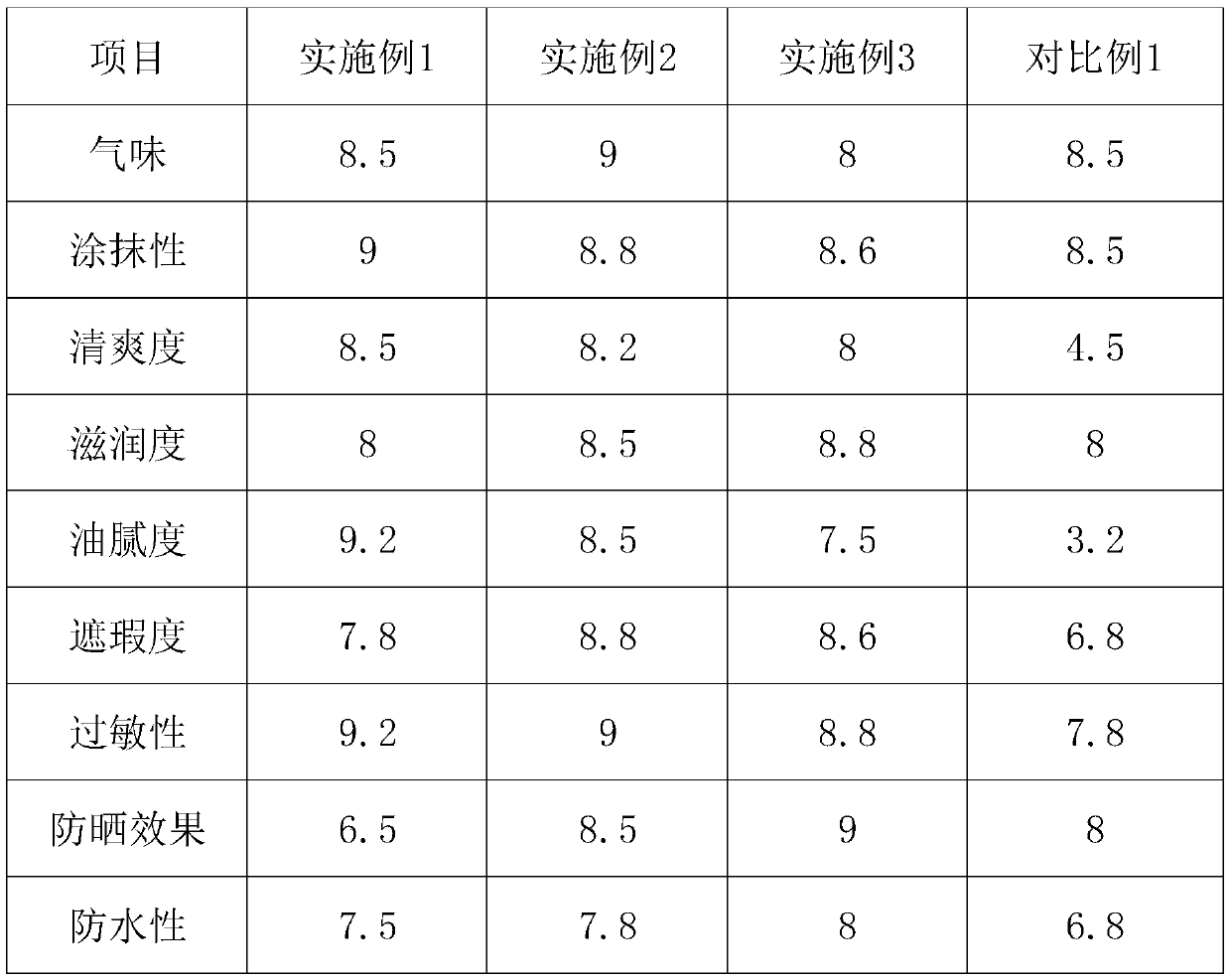

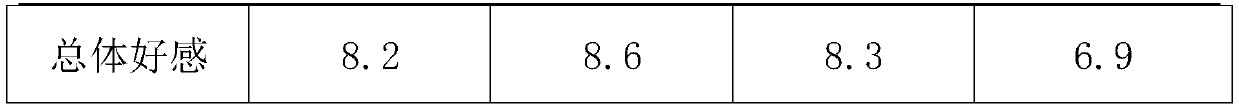

Examples

preparation example Construction

[0053] A preparation method of oil-in-water type sunscreen, comprising the following steps:

[0054] Stirring steps of oil phase materials: according to the formula ratio, put the materials in component A into the oil pan, stir and mix evenly; the stirring speed is 30-50rpm, heat up to 80-85°C, stir and keep warm for 20-40 minutes, and get oil phase materials;

[0055] Stirring steps of water phase materials: Put the materials in component B into the water pot according to the formula ratio, stir and mix evenly; the stirring speed is 30-50rpm, stir for 15-30 minutes, and then mix the materials in component C according to the formula ratio Put all the materials into the water pot, continue to stir, the stirring speed is 50-80rpm, heat up to 80-85°C, and then stir and keep warm for 20-40 minutes to obtain the water phase material;

[0056] Homogenization step: pump the water phase material into the emulsification pot, pump the oil phase material into the emulsification pot unde...

Embodiment 1

[0060] An oil-in-water type sunscreen comprises the following components by mass percentage:

[0061] Component A: Cetearyl Alcohol 1%, Emulsifier 2%, Ethylhexyl Methoxycinnamate 3%, Octocrylene 1%, Isooctyl p-Dimethylaminobenzoate 5%, Diethylaminobenzoate Aminobenzoyl Hexyl Benzoate 8%, Titanium Dioxide 0.5%, Aluminum Oxide 4%, Diethylhexyl Sebacate 3%, C12-15 Alcohol Benzoate 3%, Cyclopentasilomethicone Oxane 6%, Propylparaben 0.05%, Tocopheryl Acetate 0.1%;

[0062] Component B: the remaining water, 1% sunscreen, 0.05% citric acid;

[0063] Component C: methylparaben 0.1%, polyol 5%, sodium stearyl glutamate 0.5%;

[0064] D component: thickener 2%;

[0065] E component: essence 0.02%, preservative 0.5%.

[0066] Described emulsifier comprises main emulsifier and co-emulsifier, and the weight ratio of main emulsifier and co-emulsifier is 1:1; Wherein, main emulsifier is the mixture of glyceryl stearate and PEG-100 stearate, The co-emulsifier is a mixture of polyglycery...

Embodiment 2

[0077] An oil-in-water type sunscreen comprises the following components by mass percentage:

[0078] Component A: Cetearyl Alcohol 2%, Emulsifier 3%, Ethylhexyl Methoxycinnamate 9%, Octocrylene 5%, Isooctyl p-Dimethylaminobenzoate 5%, Diethylaminobenzoate Aminobenzoyl Hexyl Benzoate 4%, Titanium Dioxide 4%, Aluminum Oxide 0.5%, Diethylhexyl Sebacate 8%, C12-15 Alcohol Benzoate 6%, Cyclopentasilo Oxane 5%, Propylparaben 0.1%, Tocopheryl Acetate 0.5%;

[0079] Component B: the remaining water, 5% sunscreen, 0.25% citric acid;

[0080] Component C: 0.15% methylparaben, 10% polyol, 1% sodium stearyl glutamate;

[0081] D component: thickener 0.8%;

[0082] E component: essence 0.1%, preservative 0.8%.

[0083] Described emulsifier comprises main emulsifier and co-emulsifier, and the weight ratio of main emulsifier and co-emulsifier is 2: 1; Wherein, main emulsifier is the mixture of glyceryl stearate and PEG-100 stearate, The co-emulsifier is a mixture of polyglyceryl-6 stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com