A preparation method for high-strength embedded anti-reflection film on optical plastic surface

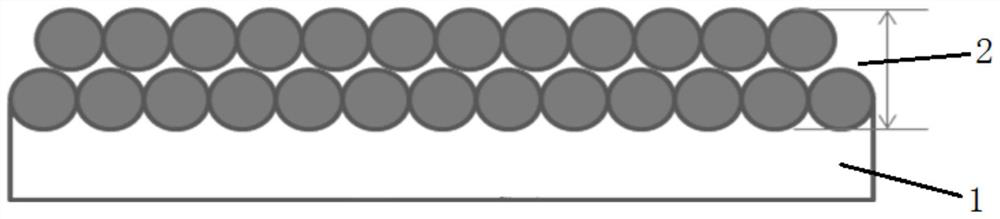

A technology of optical plastic and anti-reflection film, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. It can solve the problems of complex film structure and cumbersome operation, and achieve excellent scratch resistance, Strong bending resistance, enhanced bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Tetraethyl orthosilicate (Si(OC 2 h 5 ) 4 , TEOS), ethanol (EtOH), ammonia (NH 3 ·H 2 O) According to the molar ratio of 1:40:2, the temperature is about 25°C and the relative humidity is lower than 60%, and the environment is fully stirred for 2 hours, and after standing and aging for 7 days, a light blue latex-like silica sol is obtained, which is refluxed at 80°C Ammonia gas was removed for 24 hours to obtain a stable coating solution.

[0042] Rinse the surface of the base material with absolute ethanol for 5-10s, wipe it with a clean non-woven cloth and blow off the remaining ethanol residue on the surface with nitrogen. In a clean environment with a relative humidity lower than 50%, the antireflection film is plated on a clean polycarbonate (PC) base material by a pulling method.

[0043] Put the petri dish containing chloroform into a closed room temperature box, and volatilize and react in the dark for 30 minutes for later use.

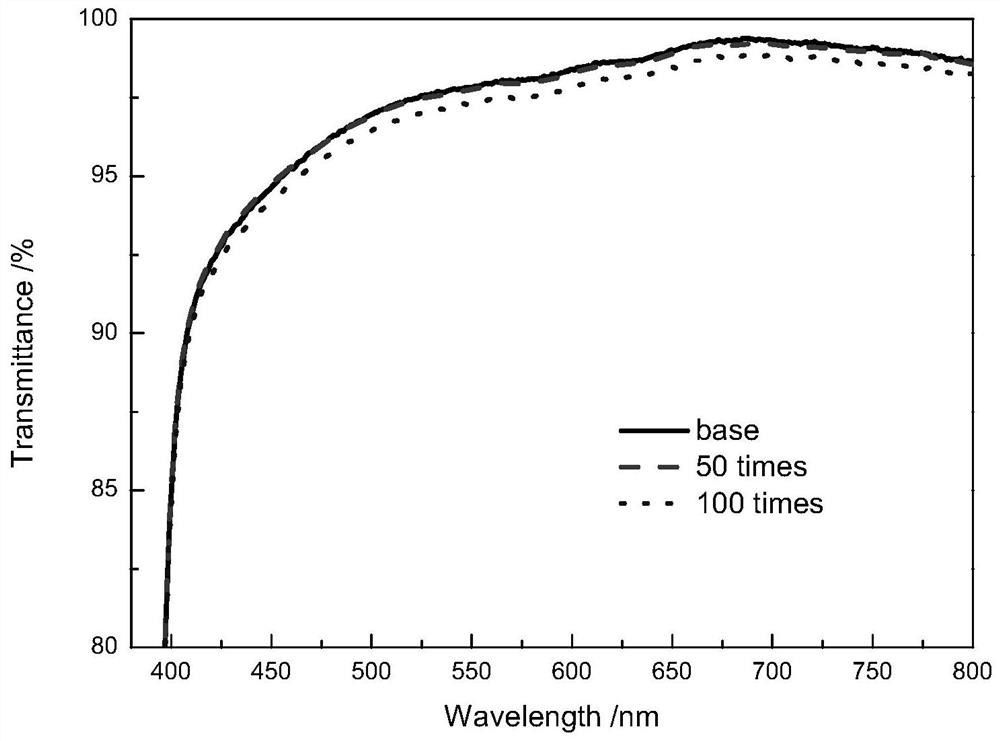

[0044] Finally, the polyca...

Embodiment 2

[0047] The preparation process of silica sol is as described in Example 1.

[0048]Rinse the surface of the base material with absolute ethanol for 5-10s, wipe it with a clean non-woven cloth and blow off the remaining ethanol residue on the surface with nitrogen. In a clean environment with a relative humidity lower than 50%, the anti-reflection film is coated on a clean polymethyl methacrylate (PMMA) substrate by a pulling method.

[0049] Put the petri dish containing chloroform into a closed room temperature box, and volatilize and react in the dark for 30 minutes for later use.

[0050] Finally, the polymethyl methacrylate substrate sample coated with silicon oxide anti-reflection film was stood upright at a distance of 5 cm above the solvent liquid level, and it was subjected to 2h atmosphere treatment under dark conditions. Remove the sample and blow off the residual chloroform gas residue on the surface with nitrogen.

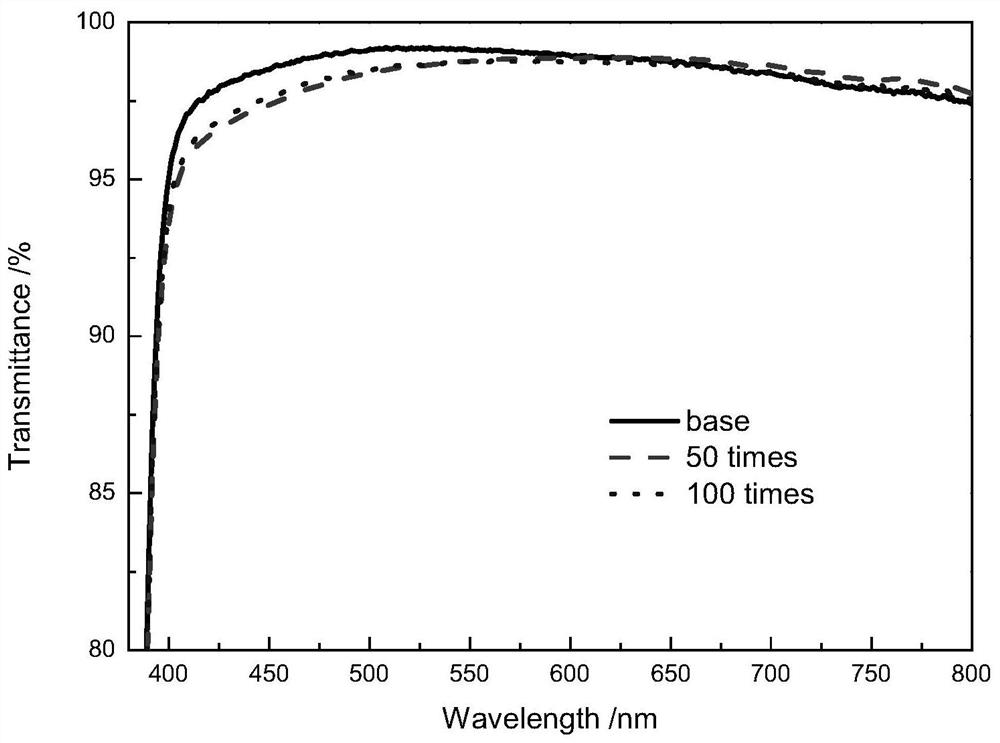

[0051] image 3 After the polymethyl methacryl...

Embodiment 3

[0053] The preparation process of silica sol is as described in Example 1.

[0054] Rinse the surface of the base material with absolute ethanol for 5-10s, wipe it with a clean non-woven cloth and blow off the remaining ethanol residue on the surface with nitrogen. In a clean environment with a relative humidity lower than 50%, the anti-reflection film is coated on a clean polymethyl methacrylate (PMMA) substrate by a pulling method.

[0055] Put the petri dish containing acetone into a closed room temperature box, and volatilize for 30 minutes for later use.

[0056] Finally, the polymethyl methacrylate substrate sample coated with silicon oxide anti-reflection film was stood upright at a distance of 4 cm directly above the solvent liquid level, and it was subjected to 2h atmosphere treatment. Remove the sample and blow off the residual acetone gas residue on the surface with nitrogen. High-strength embedded sol-gel polymethyl methacrylate surface anti-reflection film has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com