Method for controlling synthesis of molybdenum disulfide particles in mixed solvent system

A mixed solvent system and molybdenum disulfide technology, applied in the direction of molybdenum sulfide, etc., can solve the problems of uncontrollable molybdenum disulfide structure, demanding control conditions, cumbersome preparation process design, etc., achieve high repeatability, simple preparation method, and experimental The result is good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The molybdenum disulfide product prepared by the preparation method is used in single or composite form in lithium ion batteries, sodium ion batteries, photocatalysis and related fields.

[0051] The technical solutions of the present invention will be further described below in conjunction with specific examples.

Embodiment 1

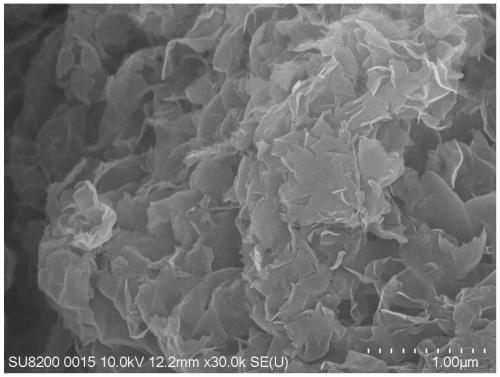

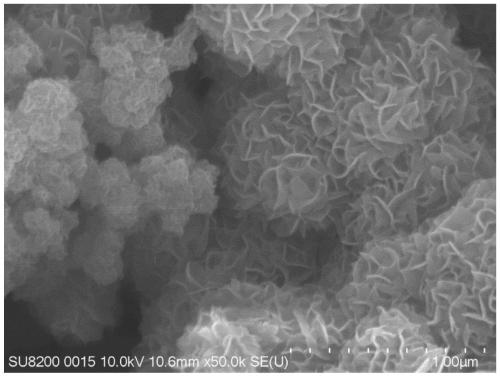

[0052] Embodiment 1: take by weighing 450mg sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 600mg thiourea (SC(NH 2 ) 2 ), stirred and dissolved in 25ml of deionized water to obtain a clear, transparent solution; 4 parts of the above solution were prepared in parallel; 10ml of deionized water, 10ml of n-propanol, 10ml of isopropanol and 10ml of cyclohexanol were added to the 4 parts of the solution , and stirred for 30 minutes to obtain solution 1, solution 2, solution 3 and solution 4 respectively; the above four solutions were respectively placed in a 50ml polytetrafluoroethylene reactor, and reacted at 200°C for 24h; the reaction product was naturally cooled to After room temperature, open reaction container, centrifuge with deionized water and ethanol, wash 3 times, obtain black powder 1 (solution 1 gained), black powder 2 (solution 2 gained), black powder 3 (solution 2 gained) respectively after natural drying again. 3), black powder 4 (obtained from solution 4). ...

Embodiment 2

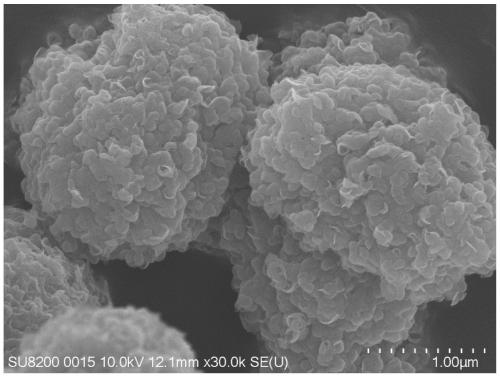

[0055] Embodiment 2: 450mg sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 600mg thiourea (SC(NH 2 ) 2 ) was stirred and dissolved in 25ml deionized water to obtain a clear, transparent solution; PVP powder was added to the solution and stirred for 30min to obtain solutions with PVP concentrations of 0.002, 0.008 and 0.02g / ml respectively, which were respectively designated as solution 5 and solution 6 and solution 7; add 10ml isopropanol respectively in 3 kinds of solutions, obtain water-isopropanol mixed solvent system after stirring; The reaction was carried out at ℃ for 24 hours; after the obtained product was naturally cooled to room temperature, the reaction container was opened, centrifuged and washed 3 times with deionized water and ethanol, and then dried naturally to obtain black powder 5 (obtained from solution 5) and black powder 6 respectively. (obtained from solution 6), black powder 7 (obtained from solution 7).

[0056] The above product was subjected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com