Ionic liquid sensibilized perovskite solar cell and preparation method thereof

A technology for solar cells and ionic liquids, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as holes in perovskite films, drop in battery open-circuit voltage, affecting device performance, etc., to improve the filling factor and The effect of photoelectric conversion efficiency, improving electrical conductivity and reducing morphology defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

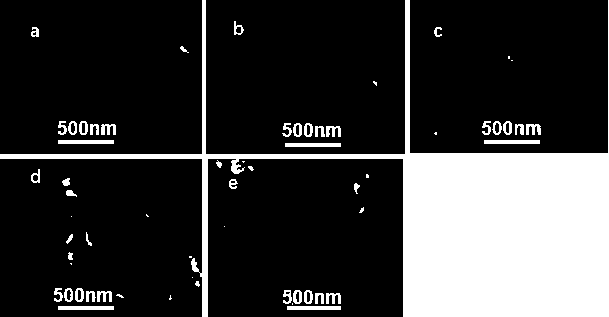

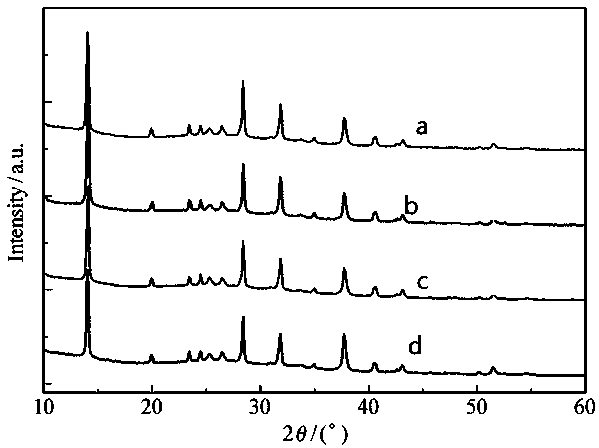

Image

Examples

Embodiment 1

[0035] A preparation method of a perovskite solar cell sensitized by an ionic liquid, comprising the steps of:

[0036] S1, the ITO substrate is ultrasonically cleaned with deionized water, absolute ethanol, and acetone in turn, and then the ITO substrate is dried with nitrogen to obtain an ITO substrate layer;

[0037] S2, 0.4mol / LTiCl on ITO substrate at 60°C 4 The solution was left to stand for 2 h, then quenched with deionized water, washed with absolute ethanol, dried with dry air, and heated with a heat gun at 500 °C for 0.5 h to prepare TiO 2 The dense layer is cooled for later use.

[0038] S3, the nano-alumina alcohol dispersion in ITO / TiO 2 The surface of the layer is spin-coated at a speed of 1500rpm for 20 seconds, and then baked at 90°C for 20 minutes to obtain an ITO / TiO 2 / Al 2 o 3 layer;

[0039] S4, the perovskite precursor material in ITO / TiO 2 / Al 2 o 3 The surface of the layer is spin-coated at a speed of 2500rpm for 20 seconds, and then baked at 9...

Embodiment 2

[0045] A preparation method of a perovskite solar cell sensitized by an ionic liquid, comprising the steps of:

[0046] S1, the ITO substrate is ultrasonically cleaned with deionized water, absolute ethanol, and acetone in turn, and then the ITO substrate is dried with nitrogen to obtain an ITO substrate layer;

[0047] S2, 0.4mol / LTiCl on ITO substrate at 60°C 4 The solution was left to stand for 2 h, then quenched with deionized water, washed with absolute ethanol, dried with dry air, and heated with a heat gun at 500 °C for 0.5 h to prepare TiO 2 The dense layer is cooled for later use.

[0048] S3, the nano-alumina alcohol dispersion in ITO / TiO 2 The surface of the layer is spin-coated at a speed of 1000 rpm for 10 seconds, and then baked at 80°C for 10 minutes to obtain an ITO / TiO 2 / Al 2 o 3 layer;

[0049] S4, the perovskite precursor material in ITO / TiO 2 / Al 2 o 3 The surface of the layer was spin-coated at 2000rpm for 10 seconds, and then baked at 90°C for 1...

Embodiment 3

[0055] A preparation method of a perovskite solar cell sensitized by an ionic liquid, comprising the steps of:

[0056] S1, the ITO substrate is ultrasonically cleaned with deionized water, absolute ethanol, and acetone in turn, and then the ITO substrate is dried with nitrogen to obtain an ITO substrate layer;

[0057] S2, 0.4mol / LTiCl on ITO substrate at 60°C 4 The solution was left to stand for 2 h, then quenched with deionized water, washed with absolute ethanol, dried with dry air, and heated with a heat gun at 500 °C for 0.5 h to prepare TiO 2 The dense layer is cooled for later use.

[0058] S3, the nano-alumina alcohol dispersion in ITO / TiO 2 The surface of the layer is spin-coated at a speed of 3000rpm for 30 seconds, and then baked at 100°C for 30 minutes to obtain an ITO / TiO 2 / Al 2 o 3 layer;

[0059] S4, the perovskite precursor material in ITO / TiO 2 / Al 2 o 3 The surface of the layer was spin-coated at a speed of 3000rpm for 30 seconds, and then baked at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com