Preparation method and application of titanium dioxide nano-rod growing on diatomite in situ

An in-situ growth and titanium dioxide technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low, wasteful and reusable rates, limited adsorption capacity of micron adsorption materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

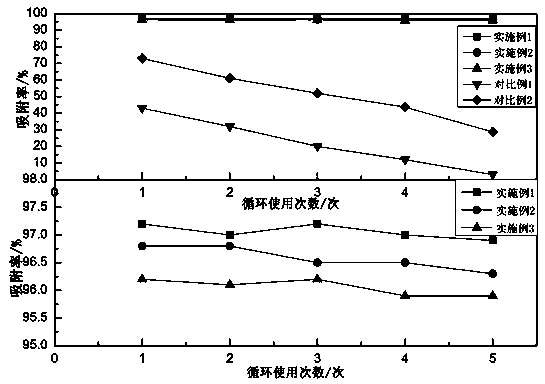

Examples

Embodiment 1

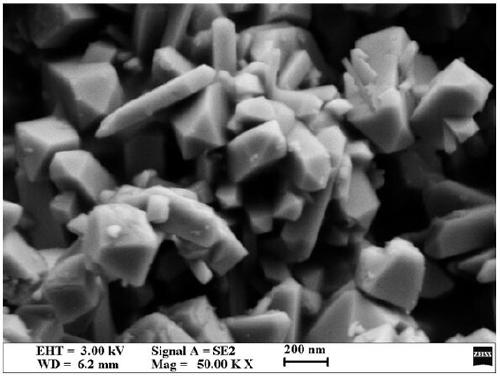

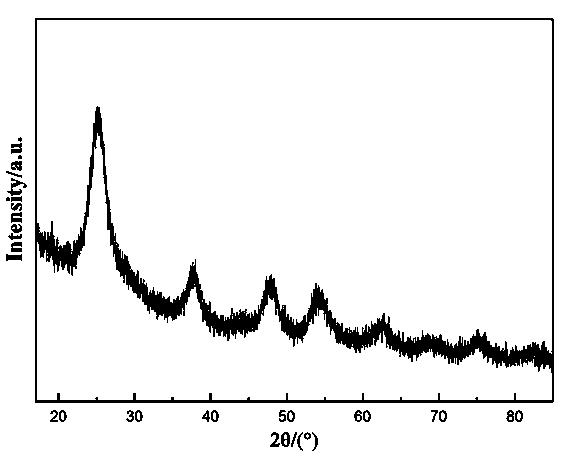

[0030] Preparation of titania nanorods grown in situ on diatomite:

[0031] (1) Drop 3ml of isopropyl titanate into 10ml of ethanol and stir magnetically for 30min;

[0032] (2) Measure 13.5g of concentrated hydrochloric acid and drop it into the solution, and weigh 0.5g of sodium dodecylbenzenesulfonate, 0.6g of ammonium oxalate, and 2g of diatomaceous earth into the solution, stir magnetically until uniform, and then continue to add 15ml deionized water, stir well;

[0033] (3) Transfer the above mixed solution into a 50ml reaction kettle lined with polytetrafluoroethylene, seal it tightly, and put it in a vacuum drying oven at 150°C for 8 hours;

[0034] (4) Centrifuge the product obtained in step (3) for solid-liquid separation, and centrifuge and wash the obtained solid product three times with absolute ethanol and deionized water respectively, then put it in an oven and dry it at 60°C for 12 hours to obtain the target product silicon In situ growth of titania nanorods ...

Embodiment 2

[0038] Preparation of titania nanorods grown in situ on diatomite:

[0039] (1) Weigh 1g of titanium nitride and add it to 10ml of ethanol, ultrasonic for 30min until uniform dispersion;

[0040] (2) Measure 15g of concentrated hydrochloric acid and drop it into the solution, and weigh 0.3g of sodium dodecylbenzenesulfonate, 0.5g of ammonium oxalate, and 2g of diatomaceous earth into the solution respectively, stir magnetically until uniform, and then continue to add 15ml Deionized water, stir well;

[0041] (3) Transfer the above mixed solution into a 50ml reaction kettle lined with polytetrafluoroethylene, seal it tightly, and put it in a vacuum drying oven at 120°C for 10h;

[0042] (4) Centrifuge the product obtained in step (3) for solid-liquid separation, and centrifuge and wash the obtained solid product three times with absolute ethanol and deionized water respectively, then put it in an oven and dry it at 60°C for 12 hours to obtain the target product silicon In sit...

Embodiment 3

[0046] Preparation of titania nanorods grown in situ on diatomite:

[0047] (1) Drop 3ml of isopropyl titanate into 10ml of ethanol and stir magnetically for 30min;

[0048] (2) Measure 15g of concentrated hydrochloric acid and drop it into the solution, and weigh 0.5g of cetyltrimethylammonium bromide, 0.5g of ammonium oxalate, and 2g of diatomaceous earth and add them into the solution respectively, stir magnetically until uniform, and then continue Add 15ml deionized water and stir well;

[0049] (3) Transfer the above mixed solution into a 50ml reaction kettle lined with polytetrafluoroethylene, seal it tightly, and put it in a vacuum drying oven at 150°C for 8 hours;

[0050] (4) Centrifuge the product obtained in step (3) for solid-liquid separation, and centrifuge and wash the obtained solid product three times with absolute ethanol and deionized water respectively, then put it in an oven and dry it at 60°C for 12 hours to obtain the target product silicon In situ gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com