Formula for polyolefin foaming building template and technology

A polyolefin foaming and building formwork technology, applied in the field of polymer materials, can solve the problems of variable product foaming density, low strength, unevenness, etc., to avoid insufficient processing, reduce density, and uniform foaming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

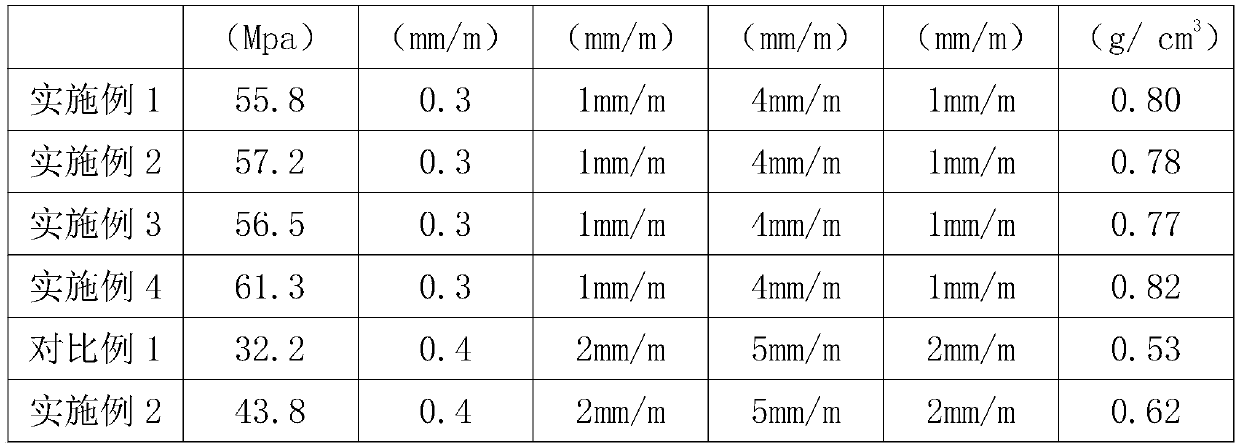

Embodiment 1

[0040] The formula and process for polyolefin foamed building formwork, the formula contains the following raw material components in parts by weight: 30 parts of polyethylene, 30 parts of polypropylene, 15 parts of sawdust, 15 parts of chaff, maleic anhydride grafted polyphenylene 1 part of ethylene, 1 part of azobisisobutyronitrile, 0.25 part of zinc oxide, 0.25 part of phosphite antioxidant, 0.75 part of zinc stearate;

[0041] Process method comprises the following steps in turn:

[0042] (1) Mixing: mix the raw materials polyethylene, polypropylene, sawdust, chaff, maleic anhydride grafted polystyrene, and phosphite antioxidants required for polyolefin foam building formwork according to the formula. After high-speed stirring by the mixer, heat is generated by friction, and it is discharged into cold mixing after reaching the set process temperature of 110°C, and discharged after reaching the set process temperature of 40°C;

[0043] (2) Granulation: Add the material obtai...

Embodiment 2

[0052] The formula and process for polyolefin foamed building formwork, the formula contains the following raw material components in parts by weight: 40 parts of polyethylene, 50 parts of ethylene-propylene copolymer, 60 parts of bran shells, 60 parts of peanut shells, maleic anhydride-benzene 20 parts of ethylene block copolymer, 15 parts of trinitrosomethylene triamine, 1 part of zinc carbonate, 1 part of hindered phenolic antioxidant, 5 parts of magnesium stearate;

[0053] Process method comprises the following steps in turn:

[0054] (1) Mixing materials: The raw materials polyethylene, ethylene-propylene copolymer, bran shell, peanut shell, maleic anhydride-styrene block copolymer, hindered phenolic antioxidant, etc. Formula mixing, high-speed stirring by the mixer, frictional heat generation, discharge into cold mixing after reaching the set process temperature of 125°C, and discharge after reaching the set process temperature of 45°C;

[0055] (2) Granulation: Add th...

Embodiment 3

[0064] The formula and process for polyolefin foamed building formwork, the formula contains the following raw material components in parts by weight: 80 parts of polypropylene, 60 parts of peanut shells, 10 parts of maleic anhydride grafted polystyrene, 6 parts of azobisisobutyronitrile part, 0.75 part of aluminum oxide, 0.5 part of phosphite antioxidant, 3 parts of magnesium stearate;

[0065] Process method comprises the following steps in turn:

[0066] (1) Mixing: Mix the raw materials polypropylene, peanut shells, maleic anhydride grafted polystyrene, and phosphite antioxidants required for polyolefin foam building templates according to the formula, and mix them at high speed with a mixer. Heat generated by friction, discharge into the cold mix after reaching the set process temperature of 115°C, and discharge after reaching the set process temperature of 43°C;

[0067] (2) Granulation: Add the material obtained in step (1) into the hopper of the granulator, and carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com