Teflon coating material and application thereof

A Teflon and coating technology, applied in the direction of coating, can solve the problems of no production of Teflon coating materials and complex components, and achieve the effect of prolonging the time of complete adhesion, prolonging the replacement time and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] According to a typical embodiment of the present invention, the polytetrafluoroethylene dispersion includes, in parts by weight: 20-35 parts of polytetrafluoroethylene with an average particle size ≤ 20 μm, 5-15 parts of xylene, N,N-dimethyl 40-60 parts of formamide, 3-10 parts of deionized water and 0.1-0.5 parts of fluorocarbon surfactant. The polytetrafluoroethylene dispersion with such components and proportions has high hardness, strong adhesion, uniform, smooth and glossy coating.

[0026] Preferably, the average particle size of the mica powder is ≤15 μm, and the average particle size of the graphite powder is ≤15 μm. The dispersion effect of the mixed solution of mica powder and graphite powder within this particle size range is good, and the wear resistance is good.

[0027] Preferably, the mixed solution of the topcoat includes, in parts by weight: 100 parts of imidazoline, 45-65 parts of toluene, 10-20 parts of deionized water, and 5-10 parts of non-ionic su...

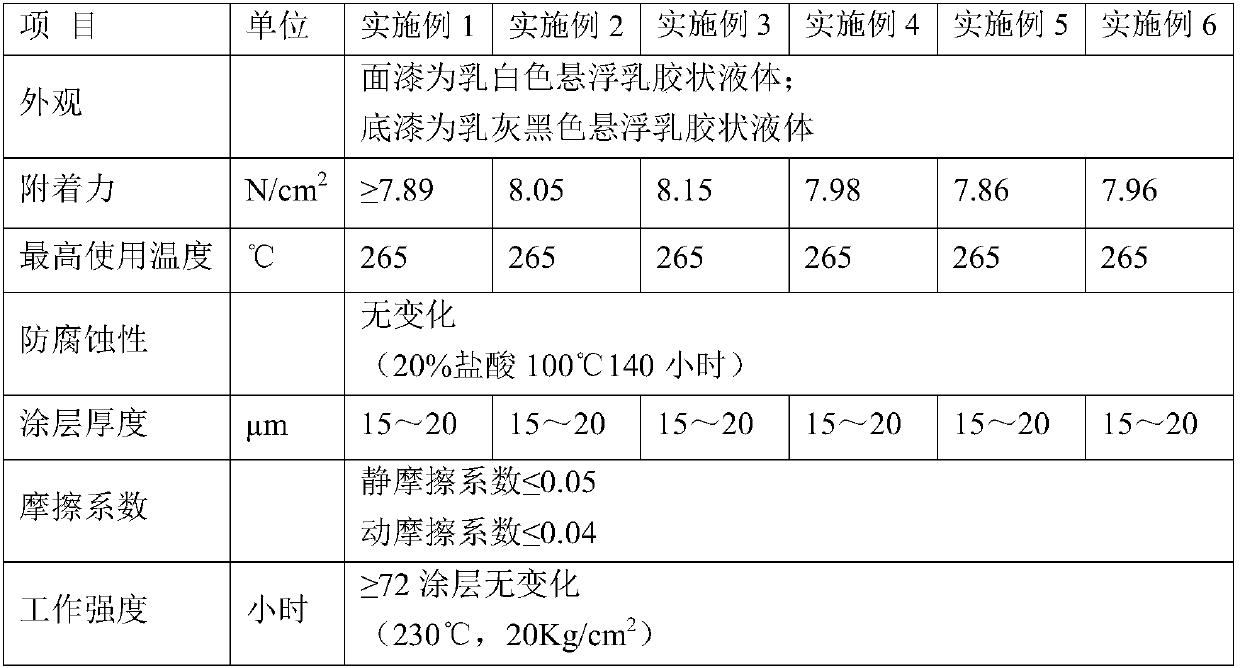

Embodiment 1

[0060] (1) Preparation of topcoat

[0061] Take 3 grams of polytetrafluoroethylene (average particle size ≤ 20 μm), 1 gram of xylene, 5 grams of N,N~dimethylformamide, 1 gram of deionized water and 0.03 gram of fluorocarbon surfactant FN~6810 to prepare polytetrafluoroethylene To tetrafluoroethylene suspension, add 0.5 g of mica powder and 0.05 g of chromium trioxide, and stir thoroughly. Then slowly add 2 grams of the prepared mixed solution (1.2 gram of imidazoline, 0.7 gram of toluene, 0.2 gram of deionized water, 0.1 gram of TritonX~100), and finally add 1 gram of terpolymer aqueous solution (methyl methacrylate 40% aqueous solution of ester / ethyl acrylate / methacrylic acid (39 / 57 / 4) terpolymer), stir well until the appearance becomes sticky.

[0062] (2) Preparation of primer

[0063] First prepare the polyamic acid salt solution: add 0.2 g of trimellitic anhydride and 0.2 g of p-phenylenediamine to 5 g of dimethylacetamide solution, and stir until completely dissolved. ...

Embodiment 2

[0073] (1) Preparation of topcoat

[0074] Take 3 grams of polytetrafluoroethylene (average particle size ≤ 20 μm), 1 gram of xylene, 5 grams of N,N~dimethylformamide, 1 gram of deionized water and 0.03 gram of fluorocarbon surfactant FN~6810 to prepare polytetrafluoroethylene To tetrafluoroethylene suspension, add 0.5 g of mica powder and 0.05 g of chromium trioxide, and stir thoroughly. Then slowly add 2 grams of the prepared mixed solution (1.2 grams of imidazoline, 0.7 grams of toluene, 0.2 grams of deionized water, 0.1 grams of TritonX~100), and finally add 1.2 grams of terpolymer aqueous solution (methyl methacrylate 40% aqueous solution of ester / ethyl acrylate / methacrylic acid (39 / 57 / 4) terpolymer), stir well until the appearance becomes sticky.

[0075] (2) Preparation of primer

[0076] First prepare the polyamic acid salt solution: add 0.2 g of trimellitic anhydride and 0.2 g of p-phenylenediamine to 5 g of dimethylacetamide solution, and stir until completely diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com