Preparation method and application of load type manganese ferrite adsorbing agent

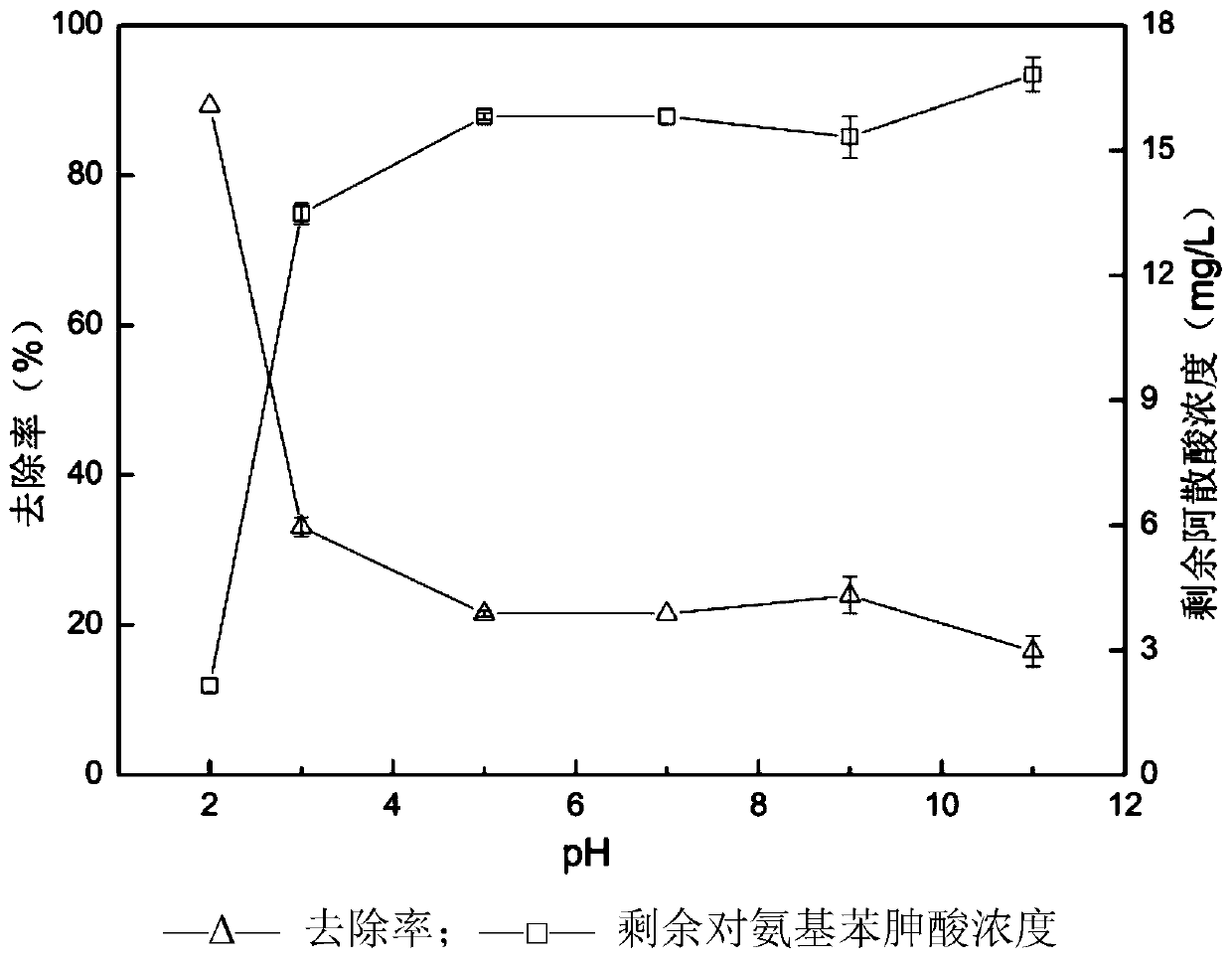

A technology of manganese ferrite and adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as aminophenylarsine acid water pollution, achieve low cost, Reduce the difficulty and cost of operation, the effect of stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the first aspect, the present invention provides a preparation method of loaded manganese ferrite adsorbent. The method comprises:

[0032] (1) Distiller's grains are mixed in a mixed solution containing divalent manganese salt and ferric salt, and the mixing conditions make divalent manganese salt and ferric salt form manganese ferrite, which is loaded on the distiller's grain carrier to obtain Supported manganese ferrite adsorbent precursor;

[0033] (2) After the precursor of the loaded manganese ferrite adsorbent is dried and calcined, the loaded manganese ferrite adsorbent is obtained.

[0034] Preferably, the mixing conditions in step (1) include: pH 9-11, temperature 50-70°C, time 3-5h.

[0035] In the present invention, distiller's grains refer to residues left after brewing such as rice, wheat, and sorghum. In order to be more conducive to the adsorption on the distiller's grain carrier, the mixing process of distiller's grains with divalent manganese salt...

Embodiment 1

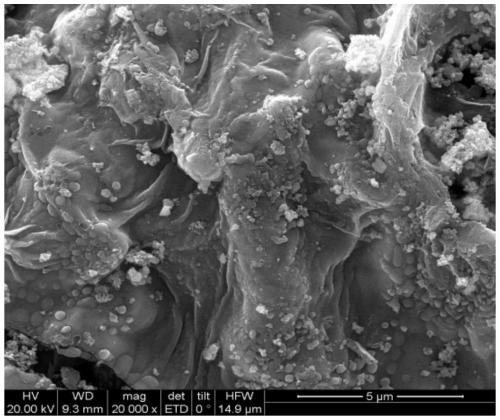

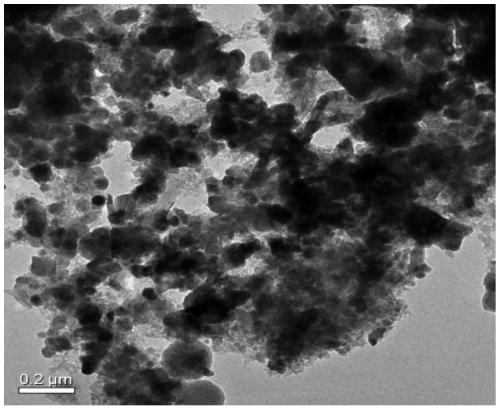

[0046] (1) Weigh 5g of distiller's grains and mix them with 100mL ultrapure water, stir at 25°C for 30min to disperse the distiller's grains completely and evenly in the water, then add 5.5g of MnSO 4 4H 2 O and 8g Fe 2 (SO 4 ) 3 Add it to distiller's grains water, and after all the solids are dissolved, adjust the pH value of the mixture to 10 with 5mol / L NaOH solution, and put the mixture in a 60°C drying oven to react for 4 hours;

[0047] (2) After separating the precipitate generated in the mixed solution (loaded manganese ferrite adsorbent precursor) from the mixed solution, wash and filter with ultrapure water several times, dry at 100°C for 24 hours, and 2 Under ambient conditions, put the precipitate in a quartz boat, put it into a tube furnace at a heating rate of 5°C / min and calcinate at 700°C for 1 hour to completely crystallize the metal;

[0048] (3) in N 2 After cooling the product obtained in step (2) to room temperature under ambient conditions, use an ag...

Embodiment 2

[0051] (1) Weigh 5g of distiller's grains and mix them with 100mL ultrapure water, stir at 25°C for 30min to completely and evenly disperse the distiller's grains in the water, then add 2.58g of MnSO 4 ·H 2 O and 14.8 g FeCl 3 ·6H 2 O was added to distiller's grains, and after all the solids were dissolved, the pH value of the mixed solution was adjusted to 9 with 5mol / L NaOH solution, and the mixed solution was put into a 50°C drying oven to react for 5 hours;

[0052] (2) After separating the precipitate (supported manganese ferrite adsorbent precursor) generated in the mixed solution from the mixed solution, wash and filter with ultrapure water several times, dry at 90°C for 30 h, and 2 Under ambient conditions, put the precipitate in a quartz boat, put it into a tube furnace with a heating rate of 5°C / min and calcinate at 600°C for 2h to completely crystallize the metal;

[0053] (3) in N 2 After cooling the product obtained in step (2) to room temperature under ambien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com