Continuous production processes of dicamba methyl ester and dicamba methyl ester emulsifiable concentrate

A dicamba methyl ester and production process technology, applied in the field of pesticides, can solve the problems of high production cost, great human injury, complicated process route, etc., achieve product yield and purity improvement, improve production operation environment, and simple process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

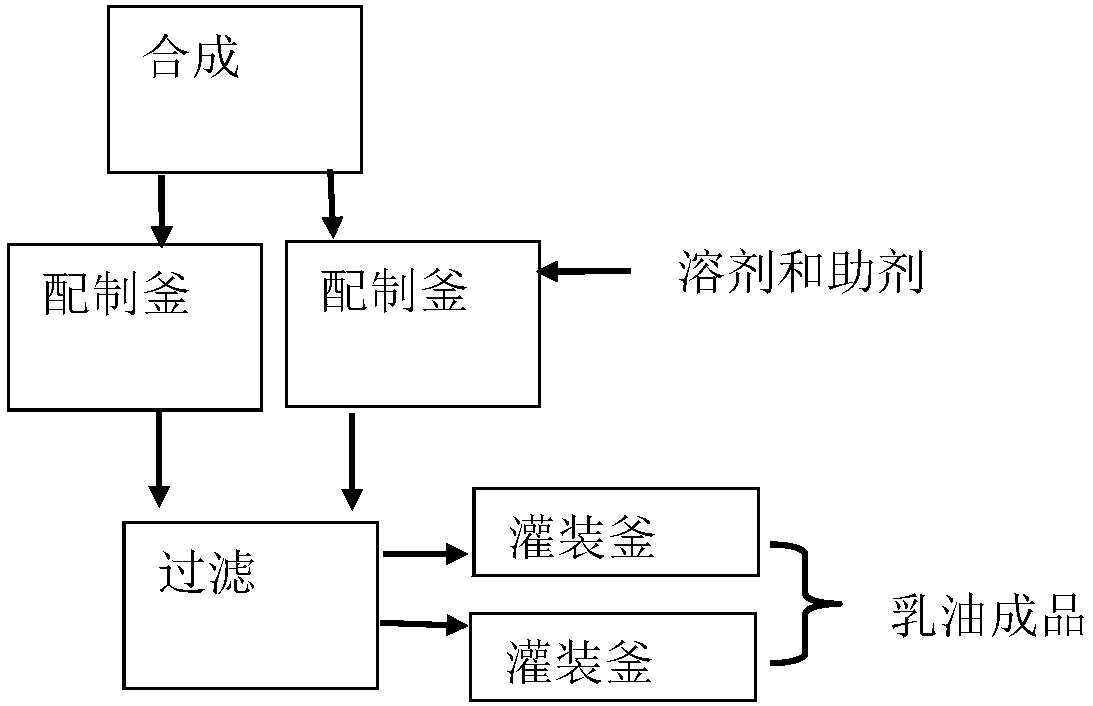

Image

Examples

Embodiment 1

[0075] Dissolve 90kg of salicylic acid in 900kg of 98% sulfuric acid at 5°C, keep it warm for 30 minutes until dissolved, add 63.6kg of bromine to generate 5-bromosalicylic acid, heat up to 35°C to pass chlorine, and synthesize 5-bromo-3 - Chlorosalicylic acid, add 360kg sulfur trioxide, 4.5kg iodine, heat preservation 50 ℃ and carry out reaction to synthesize 5-bromo-3,6-dichlorosalicylic acid, after the reaction is completed, dilute fuming sulfuric acid to 30% in terms of sulfuric acid concentration %, washed with water and dried to obtain 5-bromo-3,6-dichlorosalicylic acid. (From salicylic acid to 5-bromo-36-dichlorosalicylic acid yield is 75%)

[0076] Add 140kg of 5-bromo-3,6-dichlorosalicylic acid to 600kg of 10% liquid caustic soda, raise the temperature to 50°C until it is fully dissolved, add 60kg of tin metal powder, and react for 1 hour to control 5-bromo-3,6- Dichlorosalicylic acid is completely converted into 3,6-dichlorosalicylic acid, the metal powder is separa...

Embodiment 2

[0081] Dissolve 90kg of salicylic acid in 900kg of 98% sulfuric acid at 5°C, keep it warm for 30 minutes until dissolved, add 63.6kg of bromine to generate 5-bromosalicylic acid, heat up to 35°C to pass chlorine, and synthesize 5-bromo-3 - Chlorosalicylic acid, add 360kg sulfur trioxide, 4.5kg iodine, heat preservation 50 ℃ and carry out reaction to synthesize 5-bromo-3,6-dichlorosalicylic acid, after the reaction is completed, dilute fuming sulfuric acid to 30% in terms of sulfuric acid concentration %, washed with water and dried to obtain 5-bromo-3,6-dichlorosalicylic acid. (From salicylic acid to 5-bromo-36-dichlorosalicylic acid yield is 75%)

[0082] Add 140kg of 5-bromo-3,6-dichlorosalicylic acid into 600kg of 10% liquid caustic soda, raise the temperature to 50°C until it is completely dissolved, add 60kg of aluminum metal powder, and react for 1 hour to control 5-bromo-3,6 -Dichlorosalicylic acid is completely converted to 3,6-dichlorosalicylic acid, and the metal po...

Embodiment 3

[0087] Dissolve 90kg of salicylic acid in 900kg of 98% sulfuric acid at 5°C, keep it warm for 30 minutes until dissolved, add 63.6kg of bromine to generate 5-bromosalicylic acid, heat up to 35°C to pass chlorine, and synthesize 5-bromo-3 - Chlorosalicylic acid, add 360kg sulfur trioxide, 4.5kg iodine, heat preservation 50 ℃ and carry out reaction to synthesize 5-bromo-3,6-dichlorosalicylic acid, after the reaction is completed, dilute fuming sulfuric acid to 30% in terms of sulfuric acid concentration %, washed with water and dried to obtain 5-bromo-3,6-dichlorosalicylic acid. (From salicylic acid to 5-bromo-36-dichlorosalicylic acid yield is 75%)

[0088] Add 140kg of 5-bromo-3,6-dichlorosalicylic acid into 600kg of 10% liquid caustic soda, raise the temperature to 50°C until it is fully dissolved, add 60kg of zinc metal powder, and react for 1 hour to control 5-bromo-3,6 -Dichlorosalicylic acid is completely converted to 3,6-dichlorosalicylic acid, and the metal powder is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com