ZnO nanomaterial hybridized acrylic emulsion, polyacrylic copolymer emulsion water-based paint, waterproof roll and preparation method of polyacrylic copolymer emulsion water-based paint

A nanomaterial, water-based coating technology, used in antifouling/underwater coatings, coatings, film/flaky adhesives, etc., can solve problems such as poor adhesion, increase adhesion, improve adhesion Adhesive strength, effect of improving hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

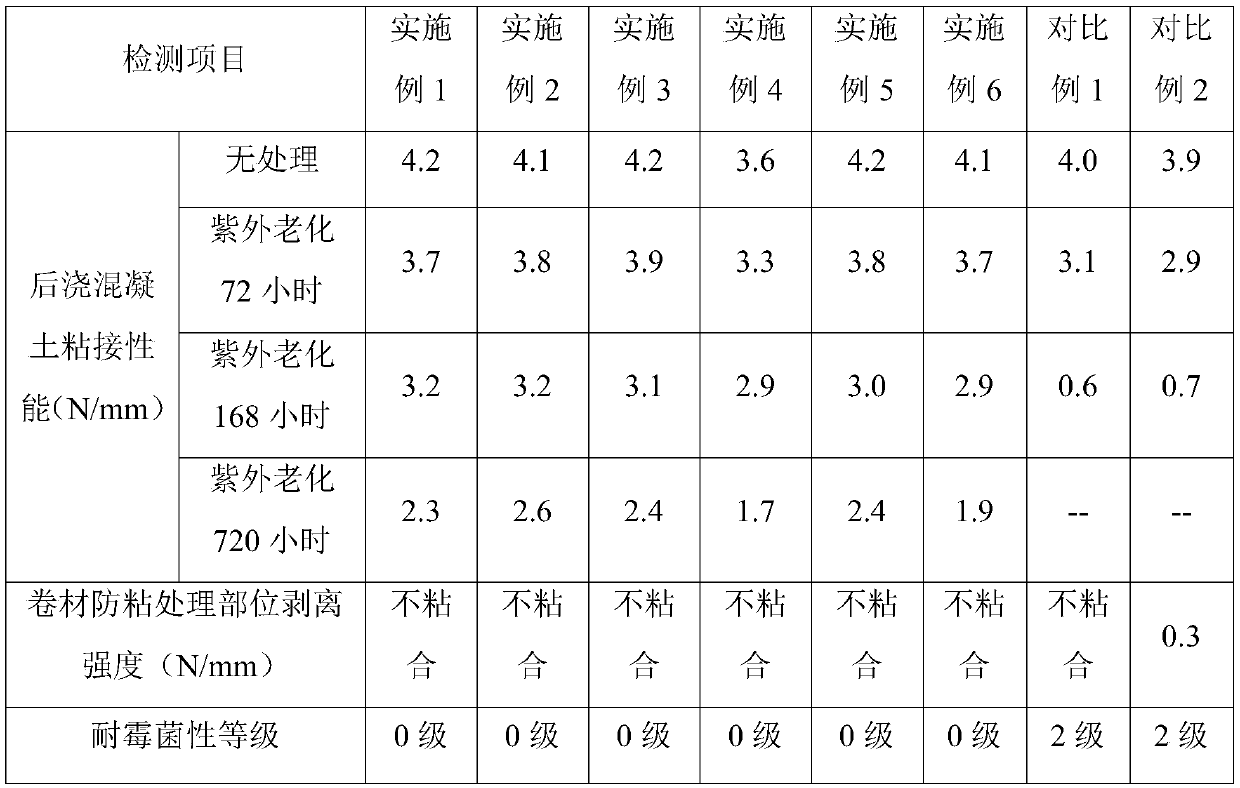

Examples

Embodiment 1

[0052] Preparation of Nano-ZnO Hybrid Emulsion

[0053] 1) Add 0.2 parts of polyphosphate to 10 parts of deionized water, start the agitator and add 1.5 parts of nano-ZnO material, then disperse at high speed for 20 minutes, then treat with ultrasonic instrument for 20 minutes, and set aside;

[0054] 2) Add 5 parts of sodium dodecylsulfonate, 38.85 parts of deionized water and 0.15 parts of ammonium persulfate into the reaction kettle, raise the temperature to 70°C under stirring, and then continuously add 0.15 parts of ammonium persulfate, 2 Parts of styrene, 5 parts of acrylic acid, 15 parts of butyl acrylate, 22.5 parts of methyl methacrylate;

[0055] 3) Add the nano ZnO suspension of step 1) after the polymerization reaction begins;

[0056] 4) After the dropwise addition, keep warm at 45° C. for 3 hours, cool, neutralize with ammonia, filter, and discharge.

[0057] Preparation of polymer coating

[0058] 1) Accurately weigh and add 10 parts of deionized water, add 1...

Embodiment 2

[0067] Preparation of Nano-ZnO Hybrid Emulsion

[0068] 1) Add 0.8 parts of polyphosphate to 8.5 parts of deionized water, start the agitator and add 3 parts of nano-ZnO materials, then disperse at high speed for 20 minutes, then treat with an ultrasonic instrument for 20 minutes, and set aside;

[0069] 2) Add 5 parts of sodium dodecylsulfonate, 38.85 parts of deionized water and 0.15 parts of ammonium persulfate into the reaction kettle, raise the temperature to 70°C under stirring, and then continuously add 0.15 parts of ammonium persulfate, 2 Parts of styrene, 5 parts of acrylic acid, 15 parts of butyl acrylate, 22.5 parts of methyl methacrylate;

[0070] 3) Add the nano ZnO suspension of step 1) after the polymerization reaction begins;

[0071] 4) After the dropwise addition, keep warm at 45° C. for 3 hours, cool, neutralize with ammonia, filter, and discharge.

[0072] Preparation of polymer coating

[0073] 1) Accurately weigh and add 10 parts of deionized water, ad...

Embodiment 3

[0082] Preparation of Nano-ZnO Hybrid Emulsion

[0083] 1) Add 0.3 parts of polyphosphate to 9.5 parts of deionized water, start the agitator and add 2 parts of nano-ZnO materials, then disperse at high speed for 20 minutes, then treat with an ultrasonic instrument for 20 minutes, and set aside;

[0084] 2) Add 5 parts of sodium dodecylsulfonate, 38.85 parts of deionized water and 0.15 parts of ammonium persulfate into the reaction kettle, raise the temperature to 70°C under stirring, and then continuously add 0.15 parts of ammonium persulfate, 2 parts of acrylonitrile, 5 parts of acrylic acid, 15 parts of butyl acrylate, 22.5 parts of methyl methacrylate;

[0085] 3) Synchronously add the nano-ZnO suspension of step 1) after the polymerization reaction starts;

[0086] 4) After the dropwise addition, keep warm at 45° C. for 3 hours, cool, neutralize with ammonia, filter, and discharge.

[0087] Preparation of polymer coating

[0088] 1) Accurately weigh and add 10 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com