HA (humic acid)/starch polymer and composite microsphere and preparation methods thereof

A technology of composite microspheres and humic acid, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of high cost and achieve low production cost, strong adsorption performance, particle size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

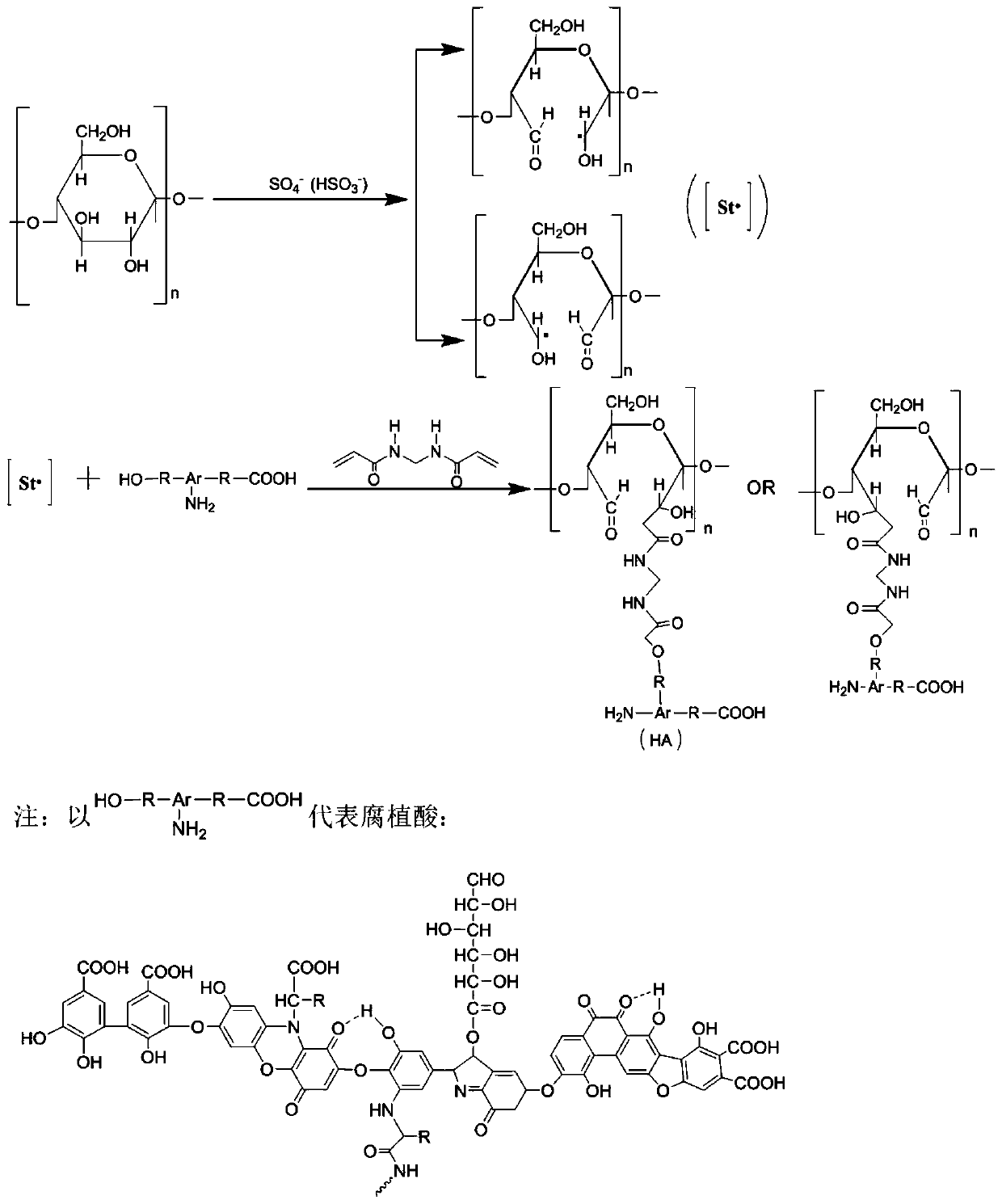

[0029] The invention discloses a preparation method of humic acid / starch composite microspheres. The specific preparation steps are:

[0030] 1) Weigh a certain quality of humic acid according to the mass ratio (humic acid: soluble starch is 5:5, 6:5, 7:5, 8:5, 9:5), stir and dissolve in 40% NaOH solution, Adjust the pH to 8-9 to prepare Solution A;

[0031] 2) According to the mass ratio of humic acid, weigh the corresponding mass of soluble starch, in 30mL of distilled water, heat and stir with solution A at 50°C to dissolve it into a homogeneous solution as the water phase, and prepare solution B;

[0032] 3) Add 0.2-0.6g of cross-linking agent N,N-methylenebisacrylamide and 0.4-0.8g of initiator potassium persulfate to solution B, keep cross-linking in a water bath at 40-70°C for 0.5-2h, and prepare Obtain solution C;

[0033] 4) Weigh 0.6-1.2g of Span-80, and weigh the corresponding mass of Tween-20 under the relative mass ratio (Span-80:Tween-20 is 3:1, 3:2, 1:1). Mix...

Embodiment 1

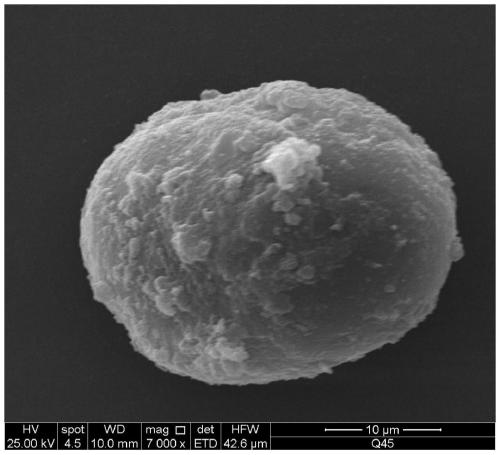

[0040] Weigh 1.5g of humic acid in a beaker, stir and dissolve in NaOH solution, adjust the pH to 8-9, and prepare solution A; weigh 1.5g of soluble starch according to the mass ratio of 5:5, and dissolve it in 30mL of distilled water , and solution A were heated and stirred in a three-necked flask at 50°C to dissolve it into a homogeneous solution as the water phase to prepare solution B; add 0.4 g of crosslinking agent N, N-methylenebispropylene Amide, 0.6g of initiator potassium persulfate, kept at 50°C for 1h in a water bath to prepare solution C; weighed 0.9g of Span-80, weighed 0.3g of Tween-20 at a relative ratio of 3:1, two Mix them together as an emulsifier, measure 80mL of liquid paraffin and dissolve it as an oil phase dispersant to prepare solution D; slowly add solution D dropwise into solution C, stir and emulsify at high speed for 0.5h, and then add 0.6g of trigger Add sodium bisulfite and continue the reaction for 4 hours; after the reaction, the product was al...

Embodiment 2

[0042] Weigh 1.8g of humic acid in a beaker, stir and dissolve in NaOH solution, adjust the pH to 8-9, and prepare solution A; weigh 1.5g of soluble starch according to the mass ratio of 6:5, and dissolve it in 30mL of distilled water , and solution A were heated and stirred in a three-necked flask at 50°C to dissolve it into a homogeneous solution as the water phase to prepare solution B; add 0.4 g of crosslinking agent N, N-methylenebispropylene Amide, 0.6g of initiator potassium persulfate, kept at 50°C for 1h in a water bath to prepare solution C; weighed 0.9g of Span-80, weighed 0.3g of Tween-20 at a relative ratio of 3:1, two Mix them together as an emulsifier, measure 80mL of liquid paraffin and dissolve it as an oil phase dispersant to prepare solution D; slowly add solution D dropwise into solution C, stir and emulsify at high speed for 0.5h, and then add 0.6g of trigger Add sodium bisulfite and continue the reaction for 4 hours; after the reaction, the product was al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com