Method of preparing uniformly carbon wrapped LiFePO4 nano composite material by using saccharomycete

A nano-composite material, yeast technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of unsatisfactory coating effect, complex reaction process, low electronic conductivity, etc. Simple synthesis process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

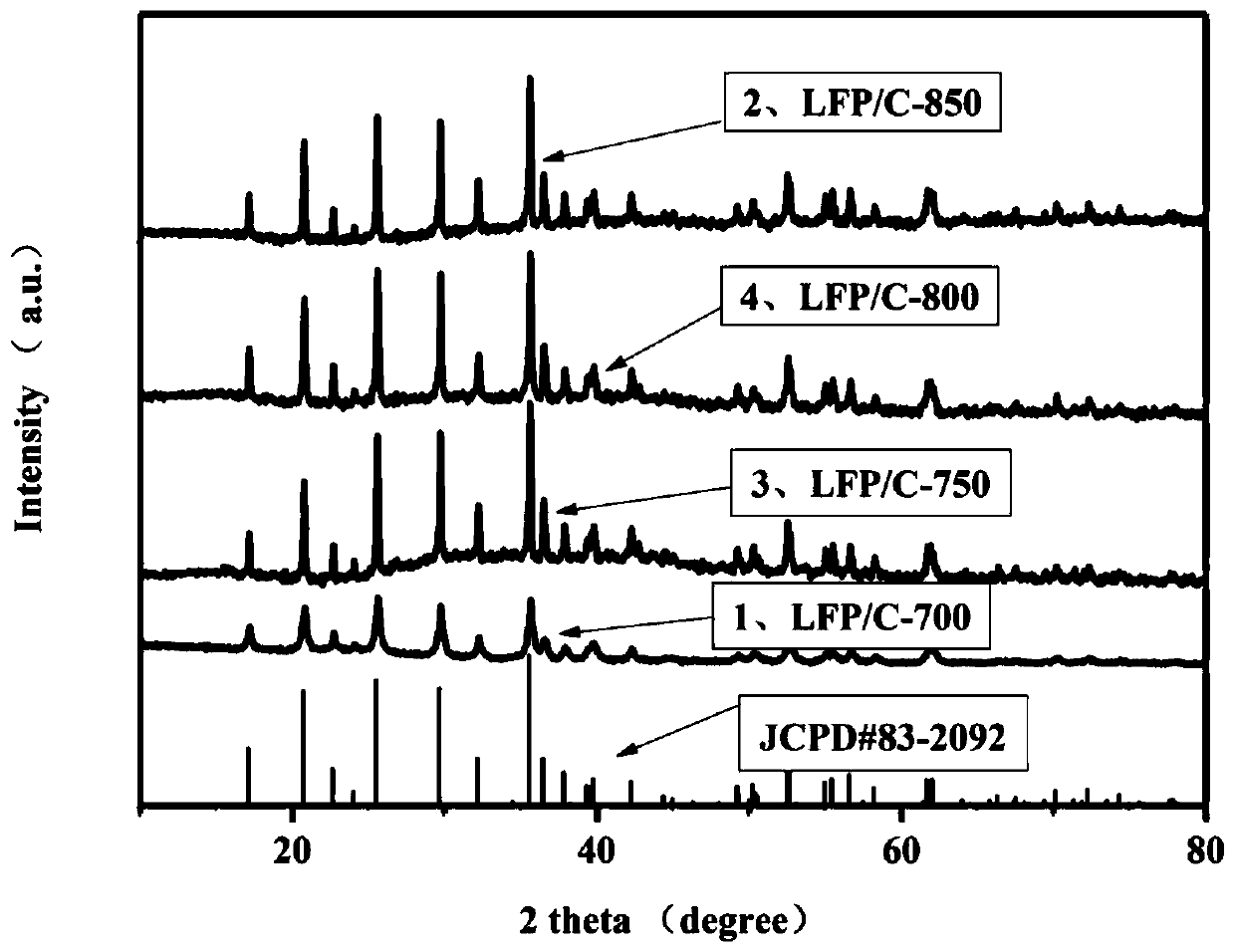

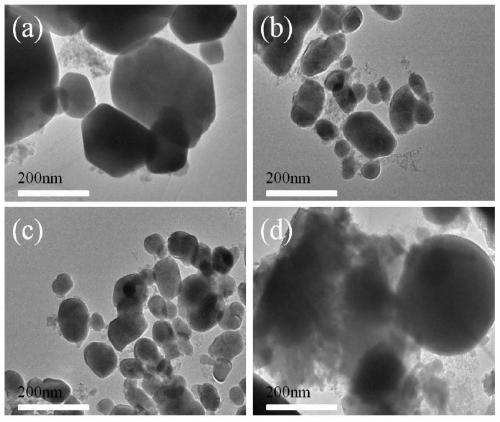

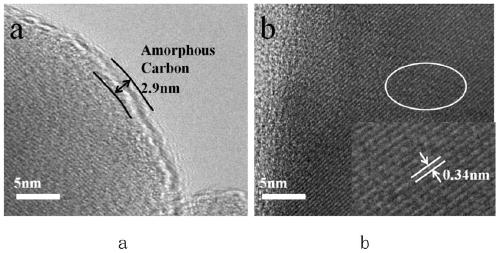

[0039] Preparation of composite materials when the sintering temperature is 800°C:

[0040] The present invention uses FeCl 2 4H 2 O, LiOH·H 2 O, NH 4 h 2 PO 4 And appropriate amount of citric acid monohydrate, dextrose and dry yeast as raw materials.

[0041] First weigh 2g of yeast and 4g of glucose, incubate in 100ml of water for 0.5 hours, the optimum temperature is 35°C, then centrifuge and wash 3 times to obtain pure active yeast cells. Weigh 1.9881g (0.01mol) FeCl 2 4H 2 O was dissolved in 80ml deionized water, and the washed yeast cells were added, and after magnetic stirring for 4 hours, 0.4196g (0.01mol) LiOH·H 2 O, 1.1505g (0.01mol) NH 4 h 2 PO 4 , 4.2028g (0.02mol) of citric acid monohydrate, the resulting solution was stirred at 80°C for 5h to form a sol, and the sol was dried in a drying oven at 120°C for 12h to form a gel. Grinding the gel in N 2 Sintered at 350°C for 4 hours under atmosphere, ground after natural cooling, and finally in N 2 Under th...

Embodiment 2

[0045] Preparation of composite materials when the sintering temperature is 700°C:

[0046] The preparation steps are the same as in Example 1, except that the sintering temperature is different. Example 2 The sintering temperature is 700°C, and the sample is marked as: LFP / C-700.

Embodiment 3

[0048] Preparation of composite materials when the sintering temperature is 750°C:

[0049] The preparation steps are the same as in Example 1, except that the sintering temperature is different. Example 2 The sintering temperature is 750°C, and the sample is marked as: LFP / C-750.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com