Preparation method of photo-induced deformation liquid crystal polymer film based on helicene molecules, polymer film and device

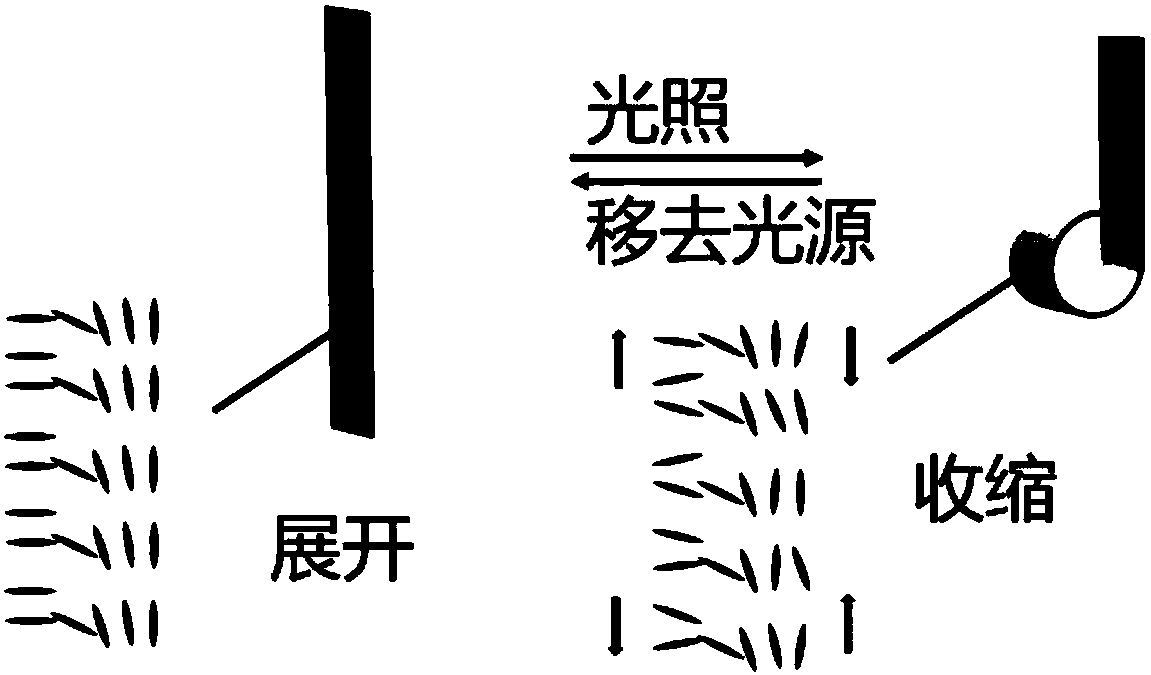

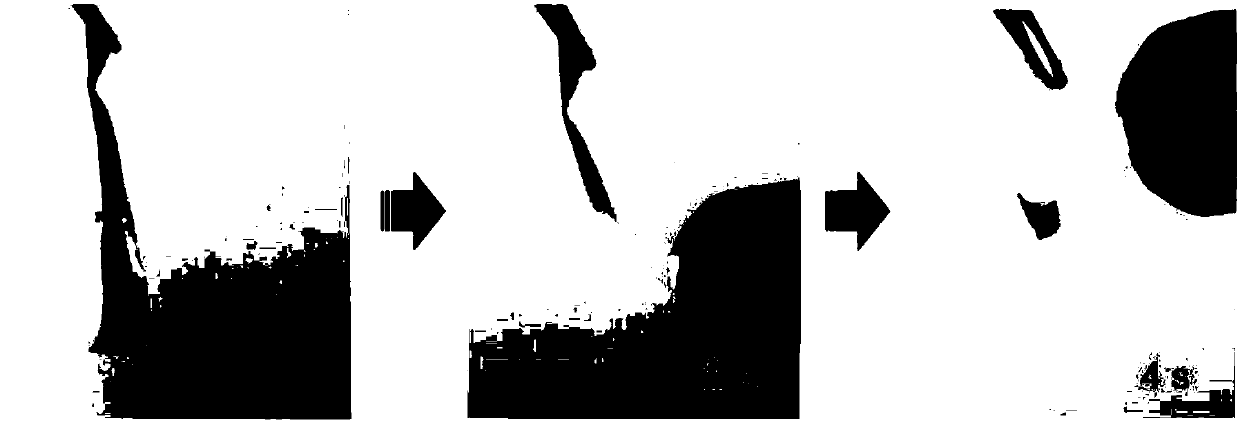

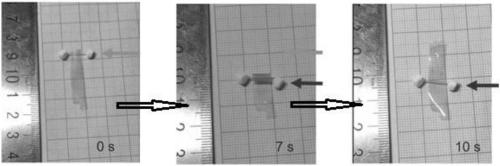

A liquid crystal polymer, photodeformation technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as limiting molecular applications, and achieve the effect of improving performance, excellent performance, fast photoresponse curling and recovery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example illustrates the synthesis of 4-(6'-propenyloxyhexyloxy)-4-methoxyphenol ester.

[0050] 1. Dissolve p-hydroxybenzoic acid (6.9g, 50mmol), potassium iodide (8.3g, 50mmol) and sodium hydroxide (5.6g, 140mmol) in 120ml deionized water, stir and heat to 75°C, after it is fully dissolved, 120ml of ethanol solution dissolved with 1-bromohexanol (10.8g, 60mmol) was added dropwise, the reaction temperature was raised to 90°C for 24h, the reaction product was poured into a large amount of deionized water acidified with hydrochloric acid (pH=3), and the white The precipitate was collected and recrystallized from ethanol to obtain 4-(6-hydroxyhexyloxy)benzoic acid.

[0051] 2. Dissolve 4-(6-hydroxyhexyloxy)benzoic acid (3.24g, 13.6mmol) in 40ml of dioxane, add N,N-dimethylaniline (2.47g, 20.4mmol), stir and heat to After 60°C, acryloyl chloride (1.85g, 20.4mmol) was slowly added dropwise and reacted for 2h; the reaction product was poured into deionized ice water aci...

Embodiment 2

[0054] This example illustrates the synthesis of 4-(6'-propenyloxyhexyloxy)-4-cyanophenolate.

[0055] 1. Dissolve p-hydroxybenzoic acid (6.9g, 50mmol), potassium iodide (8.3g, 50mmol) and sodium hydroxide (5.6g, 140mmol) in 120ml deionized water, stir and heat to 75°C, after it is fully dissolved, 120 ethanol solution dissolved with 1-bromohexanol (10.8g, 60mmol) was added dropwise, the reaction temperature was raised to 90°C for 24h, and the reaction product was poured into a large amount of deionized water acidified with hydrochloric acid (pH=3). The precipitate was collected and recrystallized from ethanol to obtain 4-(6-hydroxyhexyloxy)benzoic acid.

[0056] 2. Dissolve 4-(6-hydroxyhexyloxy)benzoic acid (3.24g, 13.6mmol) in 40ml of dioxane, add N,N-dimethylaniline (2.47g, 20.4mmol), stir and heat to After 60°C, acryloyl chloride (1.85g, 20.4mmol) was slowly added dropwise and reacted for two hours; the reaction product was poured into deionized ice water acidified with h...

Embodiment 3

[0059] This example illustrates the synthesis of 1,4-bis(4-(6'-propenyloxyhexyloxy)benzoyloxy)-2-toluene.

[0060] 1. Dissolve p-hydroxybenzoic acid (6.9g, 50mmol), potassium iodide (8.3g, 50mmol) and sodium hydroxide (5.6g, 140mmol) in 120ml deionized water, stir and heat to 75°C, after it is fully dissolved, 120 ethanol solution dissolved with 1-bromohexanol (10.8g, 60mmol) was added dropwise, the reaction temperature was raised to 90°C for 24h, and the reaction product was poured into a large amount of deionized water acidified with hydrochloric acid (pH=3). The precipitate was collected and recrystallized from ethanol to obtain 4-(6-hydroxyhexyloxy)benzoic acid.

[0061] 2. Dissolve 4-(6-hydroxyhexyloxy)benzoic acid (3.24g, 13.6mmol) in 40ml of dioxane, add N,N-dimethylaniline (2.47g, 20.4mmol), stir and heat to After 60°C, acryloyl chloride (1.85g, 20.4mmol) was slowly added dropwise and reacted for two hours; the reaction product was poured into deionized ice water acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com