Fireproof, antibacterial and mildew-resistant interior wall coating

An interior wall coating, anti-bacterial and anti-mildew technology, applied in the direction of fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of high toxicity, easy dissolution, poor durability, etc., and achieve good temperature and weather resistance, The effect of high processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

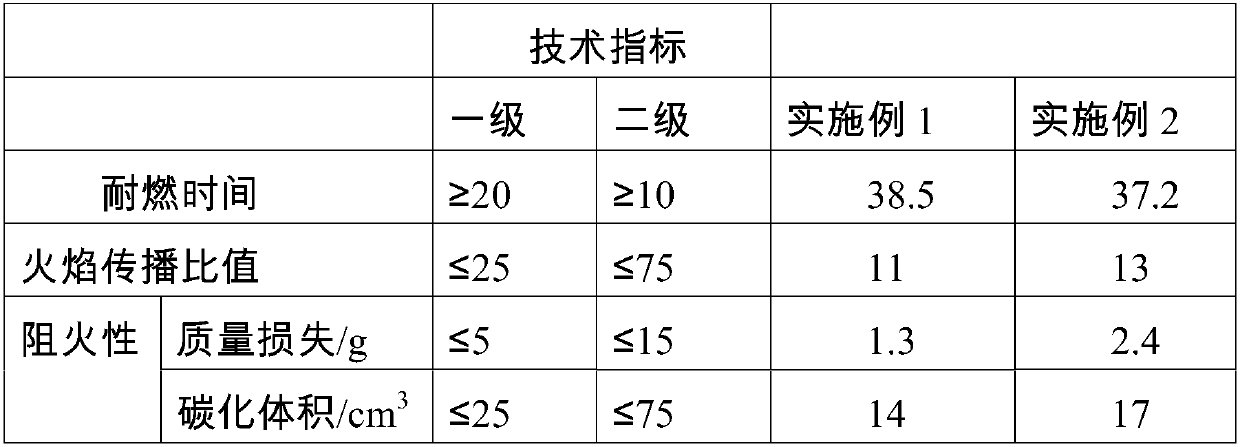

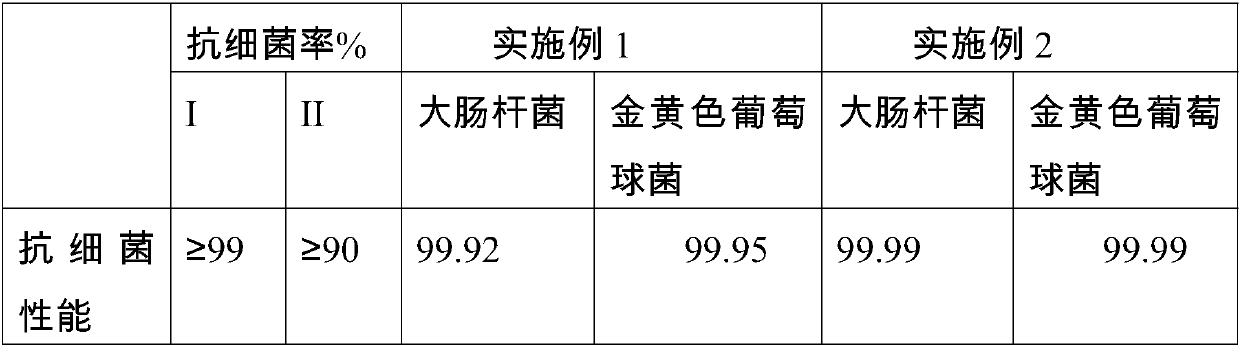

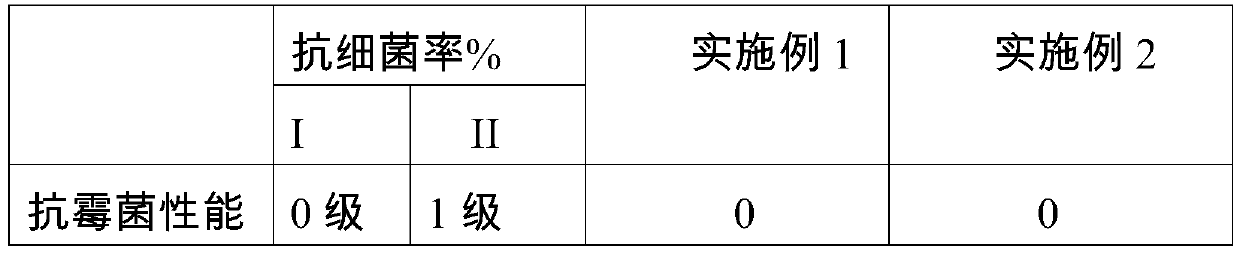

Embodiment 1

[0023] A fireproof, antibacterial, mildew-proof interior wall coating consists of the following components in parts by weight:

[0024] 15 parts of silicone acrylic resin, 10 parts of talcum powder, 8 parts of titanium dioxide, 10 parts of light calcium carbonate powder, 10 parts of kaolin powder, 8 parts of hydroxyethyl cellulose solution, 6 parts of polyvinyl alcohol, 0.5 parts of emulsified silicone oil, 0.5 parts of ethylene glycol, 0.5 parts of propylene glycol butyl ether, 0.5 parts of sodium alginate, 1 part of glyceryl tristearate, 15 parts of deionized water, 3 parts of silver-loaded zirconium phosphate antibacterial powder (JDGKP-003), phosphoric acid 7 parts of triphenyl ester.

Embodiment 2

[0026] A fire-proof, anti-bacterial, mildew-proof interior wall coating, which consists of the following mass fraction components:

[0027] 16 parts of silicone acrylic resin, 10 parts of talc powder, 8 parts of titanium dioxide, 9 parts of light calcium carbonate powder, 10 parts of kaolin powder, 8 parts of hydroxyethyl cellulose solution, 6 parts of polyvinyl alcohol, polyoxypropylene glyceryl ether 0.5 parts, 0.5 parts of ethylene glycol, 0.5 parts of propylene glycol butyl ether, 0.5 parts of casein, 1 part of monoglyceride stearate (GMS) and 17 parts of deionized water, 3 parts of silver-loaded zirconium phosphate antibacterial powder (JDGKP -003), 5 parts of triphenyl phosphate.

Embodiment 3

[0029] A fire-proof, anti-bacterial, mildew-proof interior wall coating, which consists of the following mass fraction components:

[0030] 30 parts of silicone acrylic resin, 15 parts of talcum powder, 10 parts of titanium dioxide, 12 parts of light calcium carbonate powder, 7 parts of kaolin powder, 5 parts of hydroxyethyl cellulose solution, 7 parts of polyvinyl alcohol, polydimethylsiloxane 0.3 parts of oxane, 0.6 parts of ethylene glycol, 0.8 parts of propylene glycol methyl ether acetate, 1 part of guar gum, 2 parts of ethylene bisstearamide (EBS), 20 parts of deionized water, silver-loaded zirconium phosphate antibacterial powder 5 parts (Jinda JDGKP-003), 10 parts of ammonium polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com