PCT-based antibacterial flame-retardant simulation wig fiber and preparation method thereof

A wig and neopentyl technology, applied in the field of artificial wigs, can solve the problems of long cooling time, low cooling efficiency and high cost, achieve excellent hydrolysis resistance and chemical resistance, reduce the harm to human health, and reduce the effect of cost output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

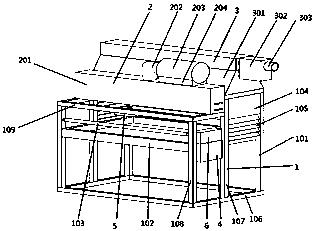

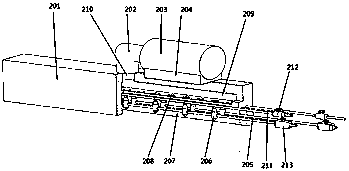

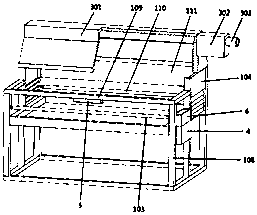

Image

Examples

Embodiment 1

[0038] A PCT-based antibacterial flame-retardant simulation wig, comprising the following steps:

[0039] (1) The raw materials by weight percentage are: PCT 80%, maleic anhydride 0.1%, polyacrylate 0.8%, chlorinated paraffin 0.1%, barium metaborate 2.7%, polyacrylate pentabromobenzyl 2.6%, three (three) Bromeopentyl) phosphate 2.5%, ethylene bis stearamide 0.2%, nanometer calcium carbonate 0.1%, nanometer silver antibacterial agent 1%, quaternary phosphonium salt 1.7%, α-conservone 2.7%, chitosan oligosaccharide 4 %, alum 1.5%;

[0040] Described PCT is the PCT that intrinsic viscosity is 0.68 and 0.74 mixed by weight ratio 1:2;

[0041] (2) The raw materials are dehumidified and dried at 50°C, 60°C, and 70°C in sequence; the total time for dehumidifying and drying is 18 hours, and the water content of the raw materials is controlled at 50ppm-80ppm;

[0042] (3) Grinding the dried raw materials in step (2), the particle size of the pulverized raw materials is 100 mesh, and ...

Embodiment 2

[0049] A PCT-based antibacterial and flame-retardant artificial wig:

[0050] The raw materials are: PCT 60%, maleic anhydride 0.5%, polyacrylate 1%, chlorinated paraffin 0.5%, barium metaborate 6%, polyacrylate pentabromobenzyl 5%, tribromoneopentyl base) phosphate ester 5%, ethylene bis stearamide 0.5%, nano calcium carbonate 0.5%, nano silver antibacterial agent 3%, quaternary phosphonium salt 4%, α-keto 4.5%, chitosan oligosaccharide 5.5%, alum 4%;

[0051] Described PCT is the PCT that intrinsic viscosity is 0.68 and 0.74 mixed by weight ratio 1:2;

[0052] (2) The raw materials are dehumidified and dried at 60°C, 70°C, and 80°C in sequence; the total time for dehumidifying and drying is 15 hours, and the moisture content of the raw materials is controlled at 50ppm-80ppm;

[0053] (3) Grinding the dried raw materials in step (2), the particle size of the pulverized raw materials is 200 mesh, and putting the pulverized raw materials into a dry powder granulator for granu...

Embodiment 3

[0060] A PCT-based antibacterial and flame-retardant artificial wig:

[0061] The raw materials are: 70% PCT, 0.2% maleic anhydride, 0.9% polyacrylate, 0.3% chlorinated paraffin, 5% barium metaborate, 4% pentabromobenzyl polyacrylate, three (tribromoneopentyl base) phosphate 4%, ethylene bis stearamide 0.4%, nano calcium carbonate 0.2%, nano silver antibacterial agent 2%, quaternary phosphonium salt 3%, α-keto 3.5%, chitosan oligosaccharide 4%, alum 2.5%;

[0062] Described PCT is the PCT that intrinsic viscosity is 0.68 and 0.74 mixed by weight ratio 1:2;

[0063] (2) The raw materials are dehumidified and dried at 55°C, 65°C, and 75°C in sequence; the total time for dehumidifying and drying is 17 hours, and the moisture content of the raw materials is controlled at 50ppm-80ppm;

[0064] (3) Grinding the dried raw materials in step (2), the particle size of the pulverized raw materials is 150 mesh, and putting the pulverized raw materials into a dry powder granulator for gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com