C-reactive protein preservation fluid, calibration product, quality control product and detection kit

A technology of reactive protein and protein protective agent, which is applied in the field of protein preservation, can solve problems such as wrong test results, waste, and can only be discarded, and achieve the effects of extending the validity period, reducing testing costs, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

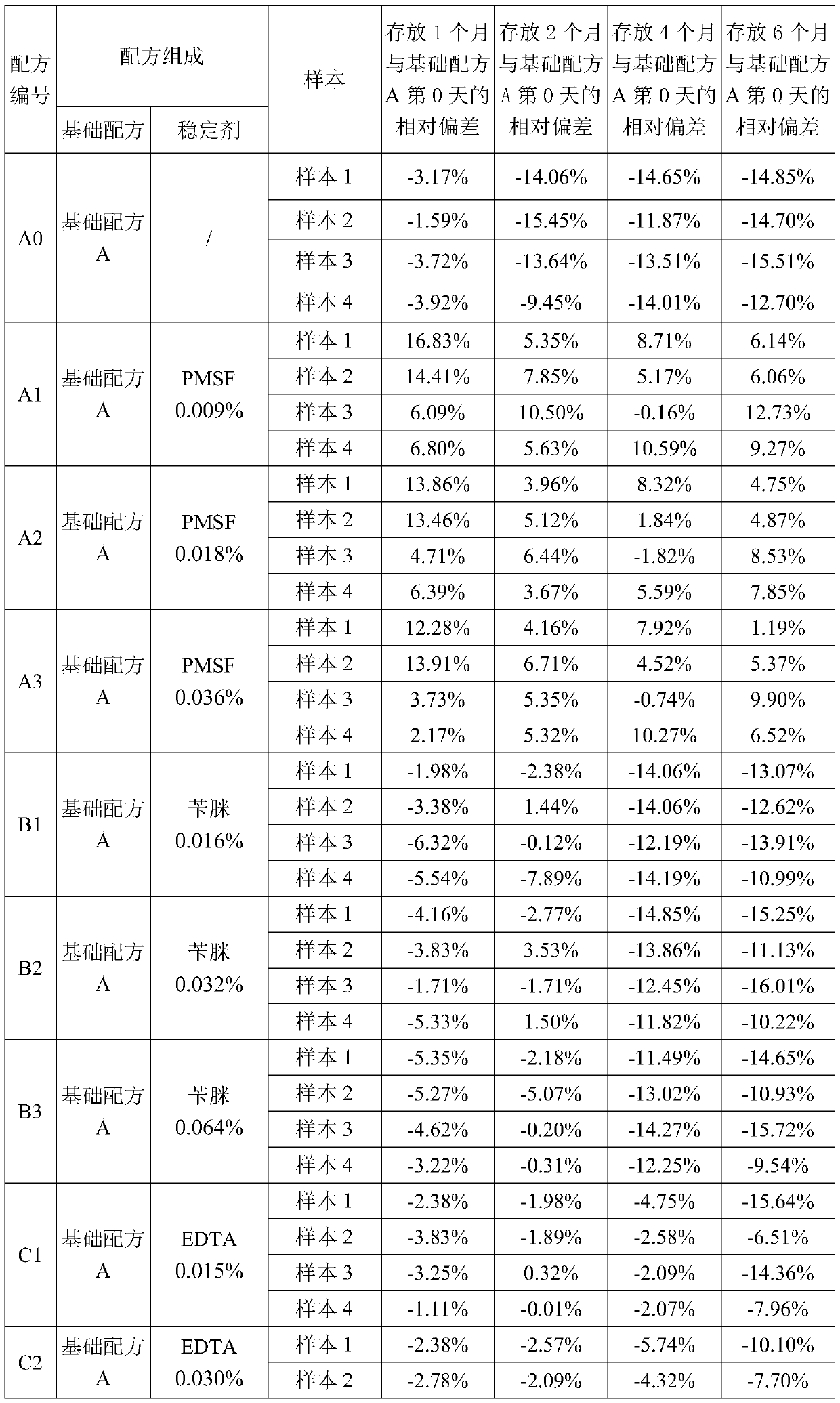

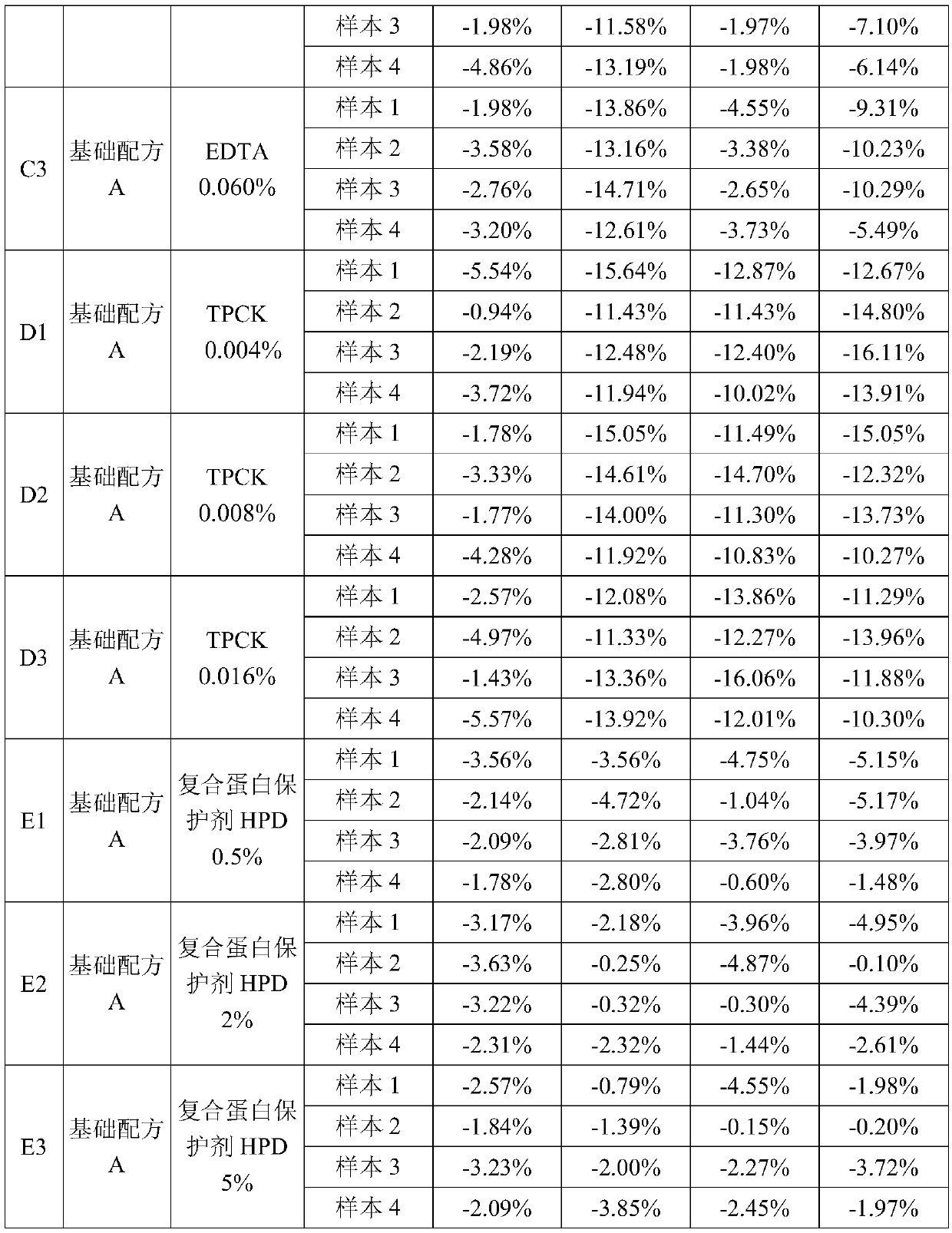

[0027] Using 20mmoL / L, pH 8.0 Tris buffer, 0.9% NaCl, 15% sorbitol, 3% sucrose, 0.1% TritonX-405 and 0.1% KroVin400 as the basic formula A, adding a stabilizer to the basic formula A to prepare C-reactive protein preservation solution.

[0028] Add C-reactive protein to the above-prepared C-reactive protein preservation solution to prepare samples to be tested with protein concentrations of 5mg / L, 20mg / L, 80mg / L and 180mg / L, respectively numbered as samples 1, 2, 3 and 4 , to investigate the change of the measured value of C-reactive protein concentration in each sample stored at room temperature for 6 months and the original C-reactive protein concentration value of the sample to be tested. The experimental results are shown in Table 1.

[0029] Table 1 Stability of C-reactive protein in C-reactive protein preservation solution for 1 month, 2 months, 4 months and 6 months under normal temperature conditions

[0030]

[0031]

[0032] In this example, the effects of usi...

Embodiment 2

[0034] C-reactive protein preservation solution was prepared with 20mmoL / L, pH 8.0 Tris buffer, 0.9% NaCl, 15% sorbitol, 3% sucrose, 0.1% TritonX-405, 0.1% KroVin400 and 2% complex protein protectant HPD.

[0035] Contrast solution: CRP (II) standard solution produced by Nippon Seiken Co., Ltd.

[0036]Take the C-reactive protein preservation solution prepared above, and prepare C-reactive protein test samples 1, 2, 3, and 4 of 5 mg / L, 20 mg / L, 80 mg / L, and 180 mg / L according to the concentration range of the sample to be tested. Take the above-mentioned contrast solution to prepare a solution corresponding to the above-mentioned C-reactive protein concentration as a comparative example, and investigate the bottle-opening stability and long-term stability of the two groups of C-reactive protein solutions. The specific experimental operation is as follows: divide the two groups of C-reactive protein solutions into 8 parts, three of which were opened for 4 hours, then covered an...

Embodiment 3

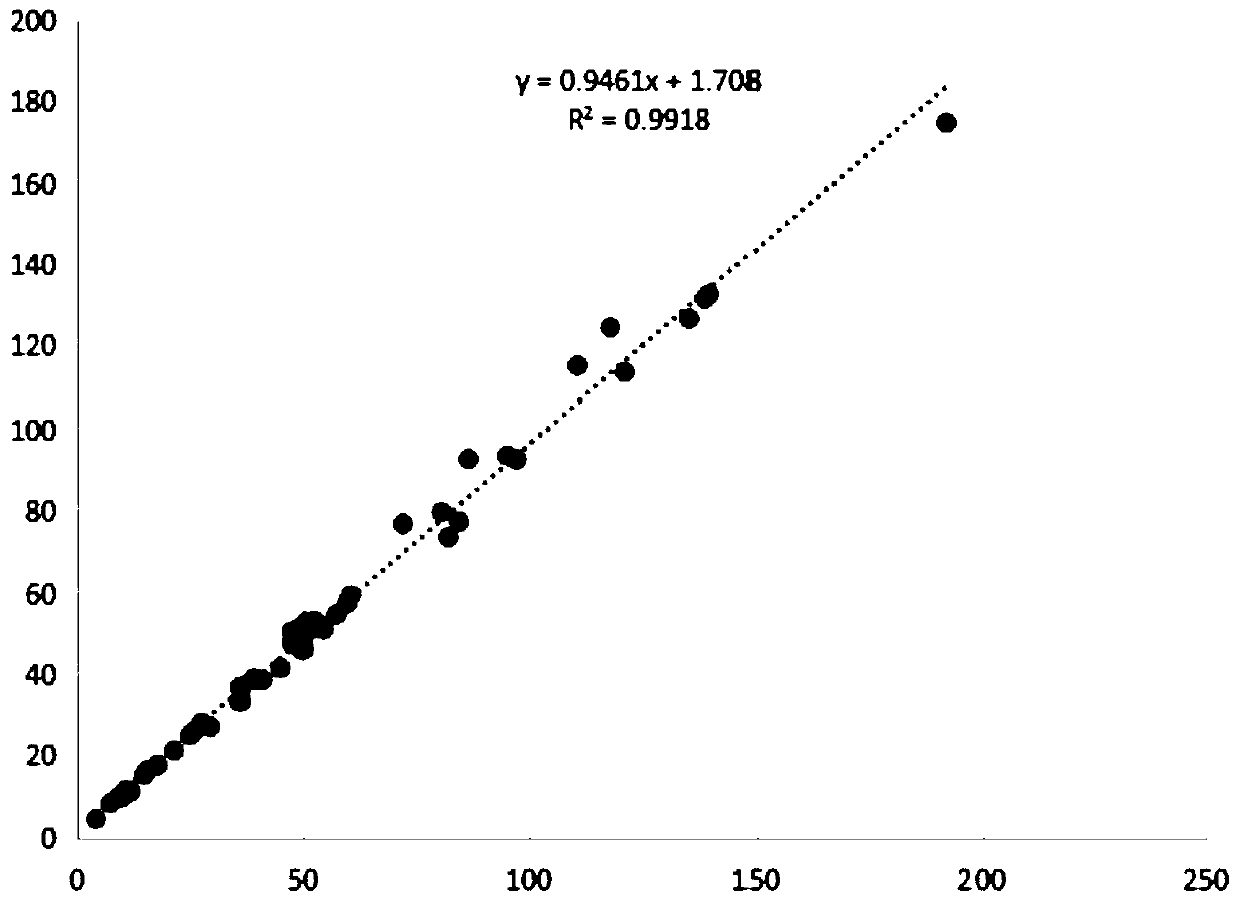

[0044] Embodiment 3: the accuracy analysis of C-reactive protein calibrator

[0045] Take 20mmoL / L pH 8.0 Tris buffer, 0.9% NaCl, 15% sorbitol, 3% sucrose, 0.1% TritonX-405, 0.1% KroVin400 and 2% compound protein protectant HPD to prepare C-reactive protein preservation solution C-reactive protein preservation solution, adding C-reactive protein at a concentration required for calibration to the C-reactive protein preservation solution to prepare a C-reactive protein calibrator. Use the above-mentioned C-reactive protein calibrator to calibrate the detection system, test 100 clinical samples, and then calibrate the detection system with the CRP (II) standard solution produced by Japan Seiken Co., Ltd., and test the 100 samples. The two sets of results were compared, and the comparison results were as follows: figure 1 shown. Experimental results show that the C-reactive protein calibrator of the present invention has the same accuracy as the CRP (II) standard solution produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com