Titanium alloy and preparation method thereof

A technology of titanium alloy and titanium powder, which is applied in the field of titanium alloy and its preparation, can solve the problems of poor toughness of Ti-Fe alloy and achieve the effect of solving poor toughness, high strength and realizing continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the titanium alloy provided by the application comprises the following steps:

[0029] The titanium powder and iron powder are mixed according to the mass ratio of 99.5:0.5-95:5, followed by forming, sintering, thermal deformation processing and vacuum heat treatment in sequence; wherein, the sintering is carried out in a hydrogen-containing atmosphere.

[0030] Among them, the oxygen content of the titanium powder and the oxygen content of the iron powder are not more than 0.3wt%. The reason may be that the toughness of the titanium alloy is sensitive to the oxygen content. When the oxygen content is higher than 0.3wt%, the toughness of the material will be greatly reduced.

[0031] Usually, the strength and hardness of pure titanium are relatively low, and it is often necessary to add some alloying elements to make the strength and hardness meet the requirements of use. However, adding Fe to Ti will greatly reduce the toughness of the alloy. ...

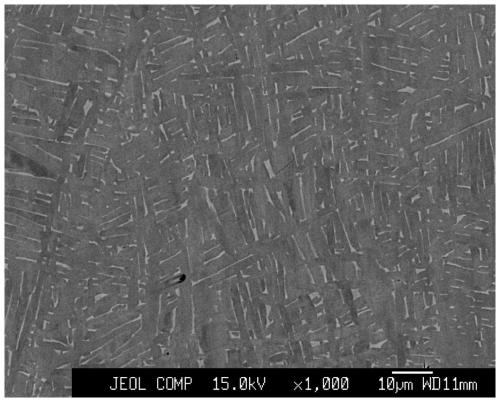

Embodiment 1

[0056] Using hydrogenated dehydrogenation Ti powder (oxygen content 0.2%) with an average particle size of 69 μm and 2.5 μm Fe powder (oxygen content 0.3%) as raw materials, the powder is weighed according to the mass ratio Ti:Fe=99.5:0.5. Mix on a mixer for 8 hours; put the powder into a rubber mold, and after being vibrated, shape it in a cold isostatic press with a pressure of 180 MPa and keep the pressure for 6 minutes; 100%), sintering at 1250°C, heat preservation for 2 hours, then lower the temperature to 250°C, heat preservation for 3 hours, and cool down to room temperature with the furnace to prepare the sintered billet; preheat the sintered billet at 950°C for 1 hour, then carry out hot rolling treatment, single deformation The amount is 10%, and the cumulative deformation is 50%; the degree of vacuum is 1×10 -2 Heat treatment is carried out in a Pa vacuum sintering furnace, the treatment temperature is 650 °C, the holding time is 8 hours, and the temperature is lowe...

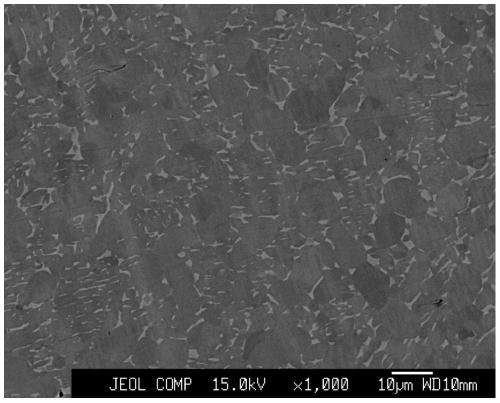

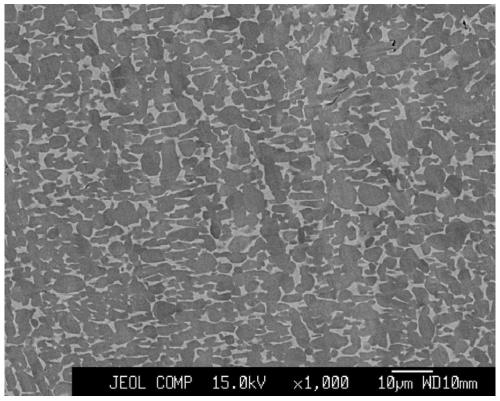

Embodiment 2

[0059] Using hydrogenated dehydrogenation Ti powder (oxygen content 0.2%) with an average particle size of 69 μm and 2.5 μm Fe powder (oxygen content 0.3%) as raw materials, the powder is weighed according to the mass ratio Ti:Fe=99:1. Mix on a mixer for 8 hours; put the powder into a rubber mold, and after vibration, shape it in a cold isostatic press with a pressure of 180 MPa and keep the pressure for 6 minutes; 10%), sintering at 1200°C, heat preservation for 1h, then cooling down to 300°C, heat preservation for 2h, cooling down to room temperature with the furnace, and preparing sintered billet; preheating the sintered billet at 960°C for 1h, then hot rolling, single The amount of deformation is 10%, and the cumulative amount of deformation is 60%; the degree of vacuum is 1×10 -2 Heat treatment is carried out in a Pa vacuum sintering furnace, the treatment temperature is 700 ° C, the holding time is 7 hours, and the temperature is lowered to room temperature with the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com