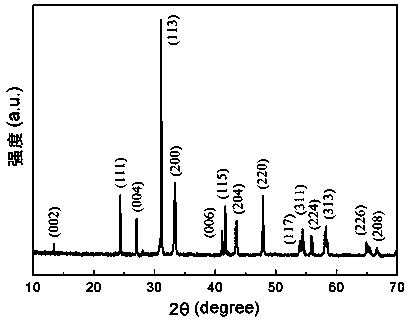

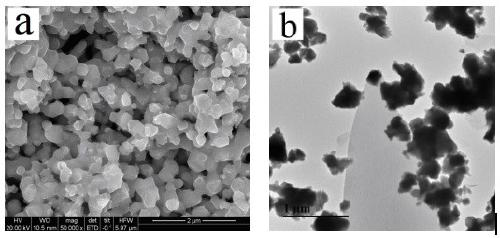

La2CuO4 catalyst material of nanometer structure and preparation method and application thereof

A nanostructure and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve lower reaction temperature, better catalytic performance, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 0.866gLa (NO 3 ) 3 ·6H 2 O, 0.242gCu (NO 3 ) 2 ·3H 2 O, 0.288gSDS and 0.005gCNTs were prepared with 50mL deionized water to prepare solution A, and ultrasonically dispersed for 5h; weighed 0.64gNaOH and prepared with 30mL deionized water to prepare solution B, and ultrasonically dispersed for 10min;

[0032](2) Under stirring conditions, add solution B dropwise to solution A to form precursor solution C, heat and stir at 60°C for 30 minutes; transfer precursor solution C to a polytetrafluoroethylene reactor and put it in an oven Medium heating reaction 6h, the temperature is 140 ℃;

[0033] (3) Take out the reacted product, filter out the precipitate, wash with deionized water and absolute ethanol respectively, and centrifuge three times to obtain the precipitate; heat the precipitate in an oven for 6 hours at 80°C, collect and obtain black product;

[0034] (4) Put the black product into a tube furnace for calcination, the calcination time is 3 hours, ...

Embodiment 2

[0038] (1) Weigh 0.866gLa (NO 3 ) 3 ·6H 2 O, 0.242gCu (NO 3 ) 2 ·3H 2 O, 0.288gSDS and 0.005gCNTs were prepared with 50mL deionized water to prepare solution A, and ultrasonically dispersed for 5h; weighed 0.8gNaOH and prepared with 30mL deionized water to prepare solution B, and ultrasonically dispersed for 10min;

[0039] (2) While stirring, add solution B dropwise to solution A to form precursor solution C, heat and stir at 60°C for 30 minutes; transfer precursor solution C to a polytetrafluoroethylene reactor and put it in an oven Medium heating reaction for 5h, the temperature is 160°C;

[0040] (3) Take out the reacted product, filter out the precipitate, wash with deionized water and absolute ethanol respectively, and centrifuge three times to obtain the precipitate; heat the precipitate in an oven for 6 hours at 80°C, collect and obtain black product;

[0041] (4) Put the black product into a tube furnace for calcination, the calcination time is 3 hours, the cal...

Embodiment 3

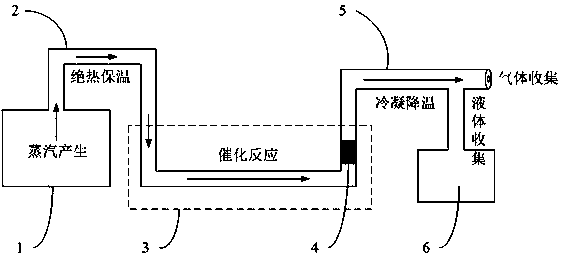

[0044] The invention provides a methanol decomposition hydrogen production device, the structure of the device is as follows image 3 As shown, it can be seen from the figure that the device includes a steam generating tank 1, a pipeline, and a condensate collecting tank 6; the pipeline includes a heating catalytic section 3 in the middle, a mixed steam introduction section 2 at both ends, and a reaction gas condensation section 5; wherein, the pipe body of the mixed steam introduction section 2 is covered with a thermal insulation protection layer, the heating and catalytic section 3 includes a heating section and a catalytic reaction section located in the heating section and close to the rear end of the heating section, and the catalytic reaction section is filled with The catalyst 4; the gas outlet of the reaction gas condensation section 5 is connected to the gas collection bag, and a condensate recovery branch pipe is arranged near the gas outlet, and the outlet of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com