Vacuum channel transistor and preparation method thereof

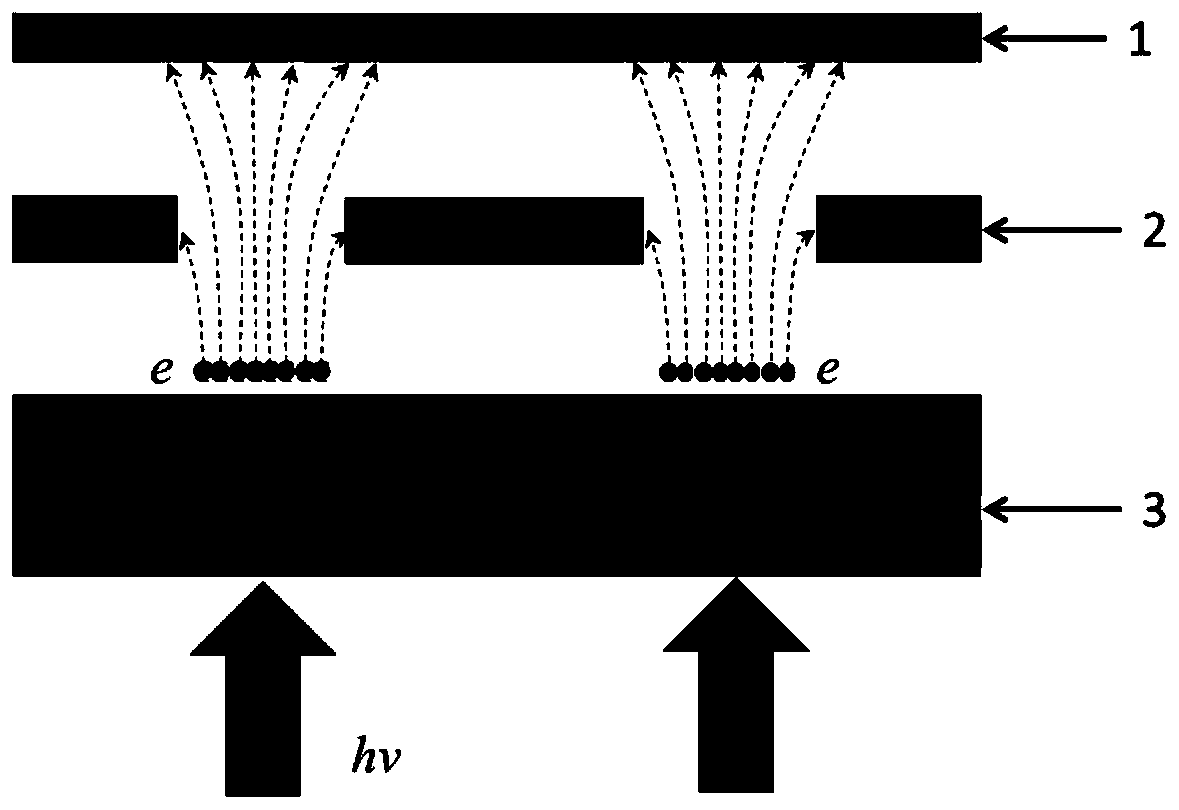

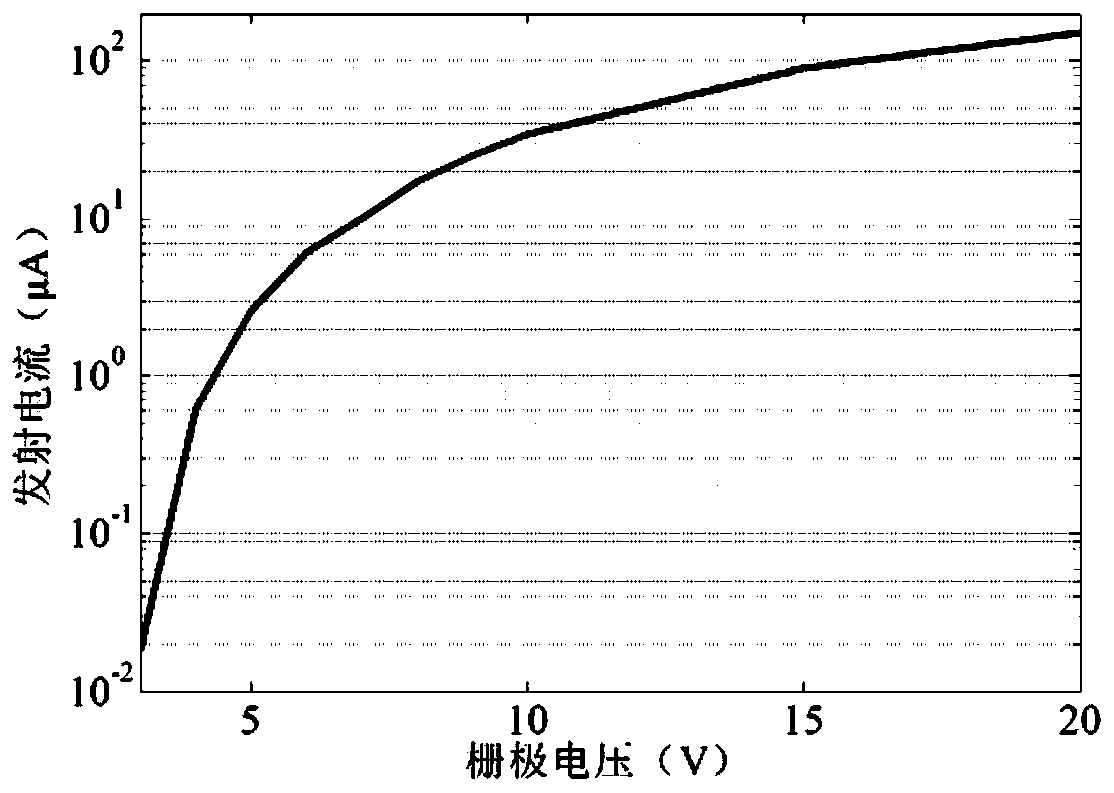

A transistor and channel technology, used in the field of vacuum channel transistors and their preparation, can solve the problems of low emission current density, difficult to improve, slow response speed, etc., and achieve high limit operating frequency, high thermal stability, and high switching ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to another aspect of the present invention, there is provided a method for preparing a photocathode vacuum channel transistor, comprising the following steps:

[0045] S1 uses organic solvents, acidic solutions and deionized water to clean the organic matter and oxides and other pollutants on the surface of the anode material;

[0046] S2 making a first insulating layer on the surface of the anode material obtained in the first step;

[0047] S3 making a gate conductive layer on the surface of the first insulating layer of the structure obtained in the second step;

[0048] S4 making a second insulating layer on the surface of the gate conductive layer of the structure obtained in the third step;

[0049] S5 using photolithography or ion beam focused etching technology to make a vacuum channel in the multilayer film material obtained in the fourth step;

[0050] S6 purifies and activates the first electrode;

[0051] In S7, the side of the structure obtaine...

example 1

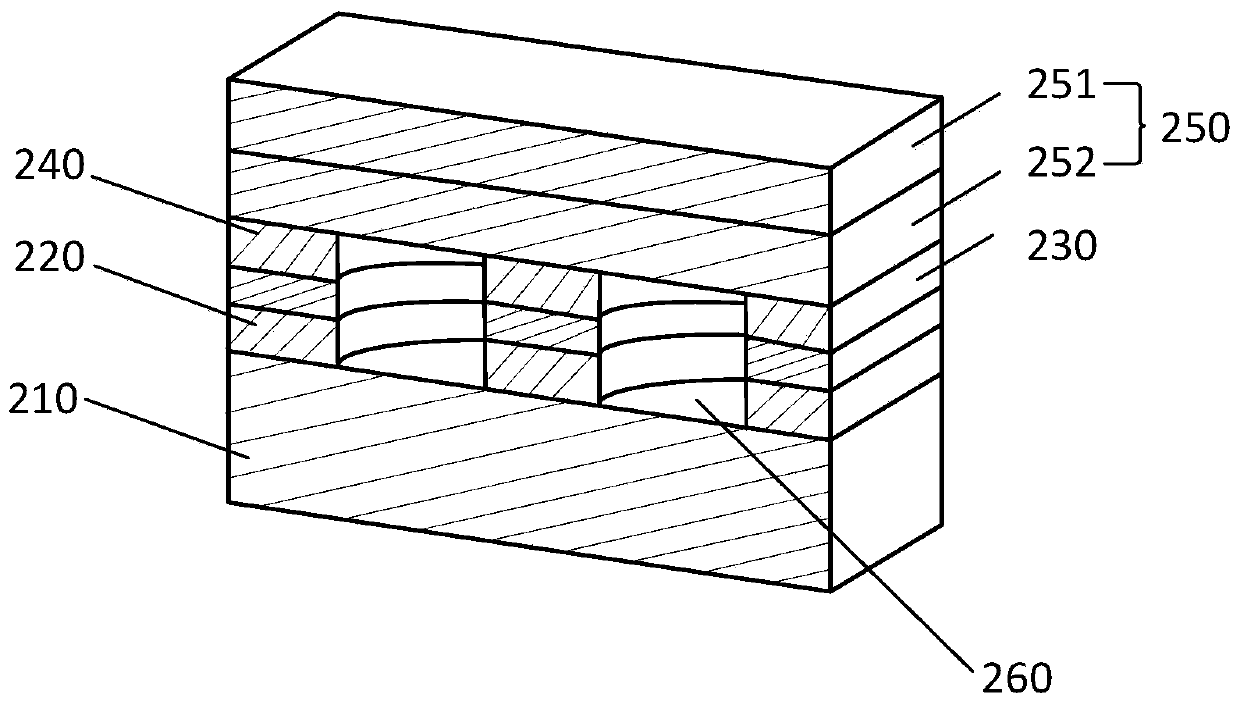

[0054] The vacuum channel transistor based on GaAs photocathode and its preparation method are as follows:

[0055] The anode material is selected as a single crystal silicon material with a thickness of 0.52mm; both insulating layers are SiO 2 material, the thickness is 5 μm; the gate layer is Si material, the thickness is 4 μm; the photocathode is GaAs photocathode, the cathode material thickness is 3 μm, the supporting substrate is a glass substrate with a thickness of 5 mm; the shape of the vacuum channel is a square column shape with a side length of 10 μm.

[0056] The preparation method of vacuum channel transistor based on photocathode is as follows:

[0057] Use acetone, absolute ethanol, acidic solution and deionized water to clean the silicon wafer surface organic matter and oxides and other pollutants;

[0058] Put the silicon wafer into the oxidation furnace, and oxidize the surface of the silicon wafer to form the first SiO 2 Insulation;

[0059] SiO obtained...

example 2

[0066] The vacuum channel transistor based on GaN photocathode and its preparation method are as follows:

[0067] The anode material is selected as Al material with a thickness of 1mm; both insulating layers are Al 2 o 3 Material, the thickness is 100nm; the gate is Mo metal material, the thickness is 100nm; the photocathode is GaN photocathode, the thickness of the cathode material is 80nm, the thickness of the glass support substrate is 0.46mm; the shape of the vacuum channel is circular, the diameter is 100nm .

[0068] The preparation method of vacuum channel transistor based on photocathode is as follows:

[0069] The first step is to use acetone, absolute ethanol, acidic solution and deionized water to clean the surface organic matter and oxides of the Al material;

[0070] The second step is to prepare the first Al on the surface of the Al material using ion sputtering deposition technology 2 o 3 Insulation;

[0071] In the third step, a Mo gate layer is prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com