Comprehensive utilization system and process for sulfur-containing natural gas development

A technology of natural gas and process, which is applied in the field of comprehensive utilization system and process for the development of sour natural gas, which can solve the problems of large desulfurization agent circulation, large investment in Claus process, and low recovery value, so as to achieve no chemical consumption and simple process , the effect of increasing sales revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

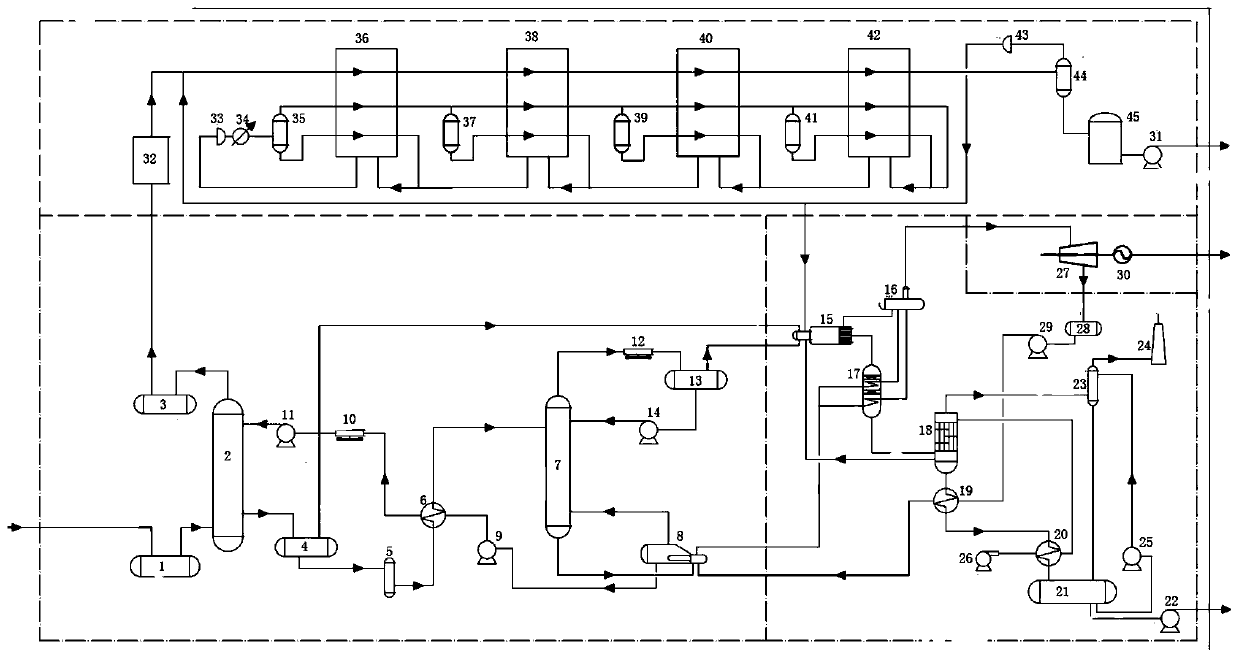

[0035] In this embodiment, the development and comprehensive utilization of a certain sour natural gas single well is taken as an example to further describe the invention and the device in detail.

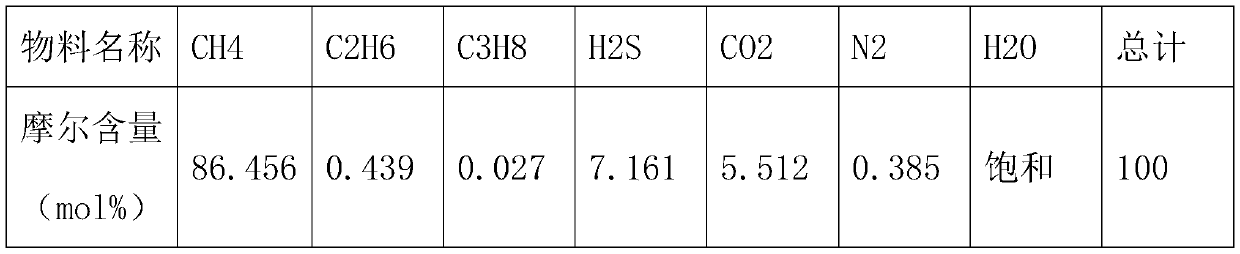

[0036] The natural gas production capacity of a sour natural gas single well is 15×104Nm3 / d; the source pressure of sour natural gas is 5.0MPa, the source temperature is 20°C, and the gas composition is shown in Table 1 below.

[0037] Table 1: Gas composition list of a certain sour natural gas well

[0038]

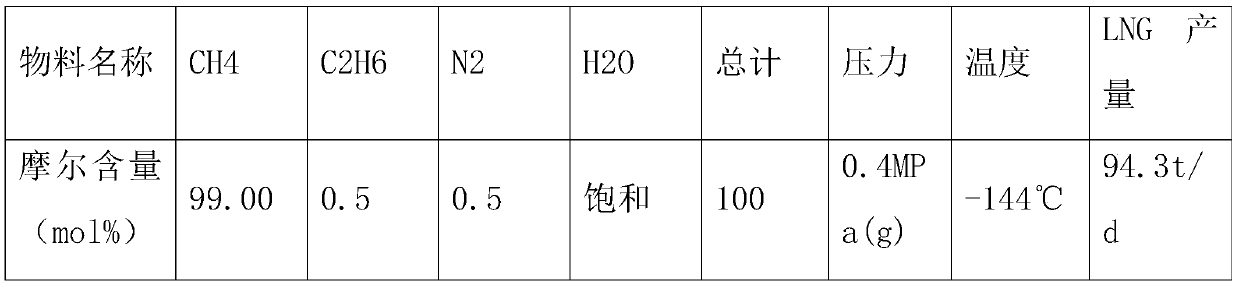

[0039] Table 2: Sour Natural Gas LNG Temperament and Product Parameters

[0040]

[0041] The desulfurization and application process of a sour natural gas single well natural gas is as follows:

[0042] Sour natural gas (containing H2S 7.161%, CO 2 5.512%) first pass through the gravity sedimentation separator 1 to remove the entrained liquid droplets and solid impurities; then enter the absorption tower 2 and contact with the MDEA liquid at 40 ° C in countercurren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com